Abstract With the aggravation of global climate change and population growth, afsaltning af havvand technology has become a core solution for water security in arid regions. This article takes reverse osmosis technology as an entry point, systematically analyzes the working principle of seawater desalination, and discusses its technological advantages, environmental benefits, and economic value in combination with typical cases and authoritative data around the world. The article cites the latest report of the International Desalination Association (IDA) and other organizations to show the path of technological innovation through multi-dimensional comparisons, providing a scientific basis for the sustainable management of water resources.

Technical Principles and Processes of Desalination

1. Reverse osmosis technology: a revolutionary breakthrough in microscopic filtration

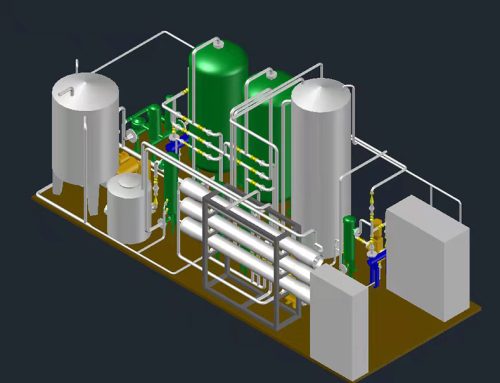

Reverse osmosis (RO) is currently the most mainstream desalination technology, the core of which is to drive seawater through semi-permeable membranes by high pressure. As shown at the Perth Desalination Plant, the process consists of three stages:

- Pre-treatment: Multi-layer filtration to remove suspended solids and microorganisms (up to 5 microns);

- Membrane separation: at a pressure of 60-80 bar, a polyamide membrane with a pore size of 0.0001 microns retains 99.7% of the salt;

- Post-treatment: Addition of minerals to adjust the pH value to ensure that the water quality meets WHO drinking water standards.

2. Multi-Stage Flash Evaporation: Thermally Driven Scale-Up Production

Multi-stage flash (MSF) evaporates and condenses seawater by depressurizing it step by step. Take the Saudi Arabia Jubail III project as an example, its 900,000 tons/day capacity relies on nuclear power plant waste heat, which improves energy utilization by 40%. Compared with RO, MSF is more suitable for combining with cogeneration projects (Table 1).

Comparison of mainstream desalination technologies and land civilization.

| Indicators | Reverse osmosis (RO | Multi-stage flash vaporization (MSF) |

|---|---|---|

| Energy consumption (kWh/m³) | 3-4 | 10-15 |

| Applicable salinity | 35,000 ppm | 50,000 ppm |

| Investment Costs | Medium Low | High |

| Maintenance Complexity | Low | High |

Global Practices: From Desert Country to Mega-Engineering

a. The Middle East Model: Synergistic Innovation in Energy and Desalination

Saudi Arabia has built the world’s largest desalination network through its “Vision 2030”, producing over 7 million cubic meters of fresh water per day, 60% of which is produced using RO technology. The Tawil project in the United Arab Emirates (daily production capacity of 900,000 tons) adopts corrosion-resistant duplex stainless steel membrane modules developed by CEC, with a desalination rate of 99.9%.

b. China’s Contribution: Double Breakthrough in Technology and Production Capacity

China has already built benchmark projects such as Zhoushan Liuheng Island (36,000 tons/day) and Qingdao Dongjiakou (100,000 tons/day), etc. The Bohai Bay desalination base to be put into operation in 2025 will adopt the coupled technology of “nuclear energy + RO”, and the annual water supply is expected to reach 120 million cubic meters.

Balancing Environment and Economy: Challenges and Solutions

1. Ecological impacts of concentrated brine discharge

The salinity of desalinated concentrated brine can reach 70,000 ppm, requiring accelerated ocean mixing through diffusers. The Ashkelon project in Israel utilizes a multi-point discharge system to reduce the salinity gradient to within 3% of natural seawater.

2. Low-carbon transition in energy consumption

The NEOM New City project in Saudi Arabia integrates photovoltaic power generation and gravity energy storage to reduce RO energy consumption to 2.8 kWh/m³. According to IDA’s estimation, if the global desalination industry fully applies renewable energy, the annual carbon emission can be reduced by 120 million tons.

Future Prospects: Technology Iteration and Industrial Integration

a. Frontier Exploration of Forward Osmosis and Graphene Membranes

The FO-MBC system developed by MIT utilizes osmotic pressure difference to drive desalination, with 30% lower energy consumption than RO. The graphene membrane has an ion screening efficiency of 5 times that of conventional materials and is now in the pilot stage .

b. Comprehensive utilization of seawater chemical resources

Middle Eastern enterprises extract bromine, magnesium, and other elements from concentrated brine, with an added value of $0.5/m³. The “desalination-salt chemical” complex built by SWCC in Saudi Arabia recovers more than 2 million tons of sodium chloride annually.

Data-driven Decision Optimization

1. Intelligent Operating System

The Dubai DEWA project adjusts membrane pressure and flow rate in real time through AI algorithms, extending equipment life by 20%. Its digital twin platform simulates capacity fluctuations in extreme climates and improves decision response by 50%.

2. Cost reduction and market expansion

Over the past decade, the cost of RO desalination has fallen from US$1.5/m³ to US$0.5/m³. The global desalination market is expected to exceed US$30 billion by 2027, growing at a CAGR of 8.4%.

Konklusion

Desalination technology, from the laboratory to industrialization, not only reshaped the water resources pattern of arid areas but also spawned cross-innovation of green energy, new materials, and intelligent control. With technological advances and policy support, this scientific and technological feat of “asking for water from the sea” will continue to energize the sustainable development of mankind. As the president of the International Water Association said, “Desalination engineering is not an option but a necessity – it is the blue link between ocean civilization and land civilization.”