Industrial Reverse Osmosis Water Purification System

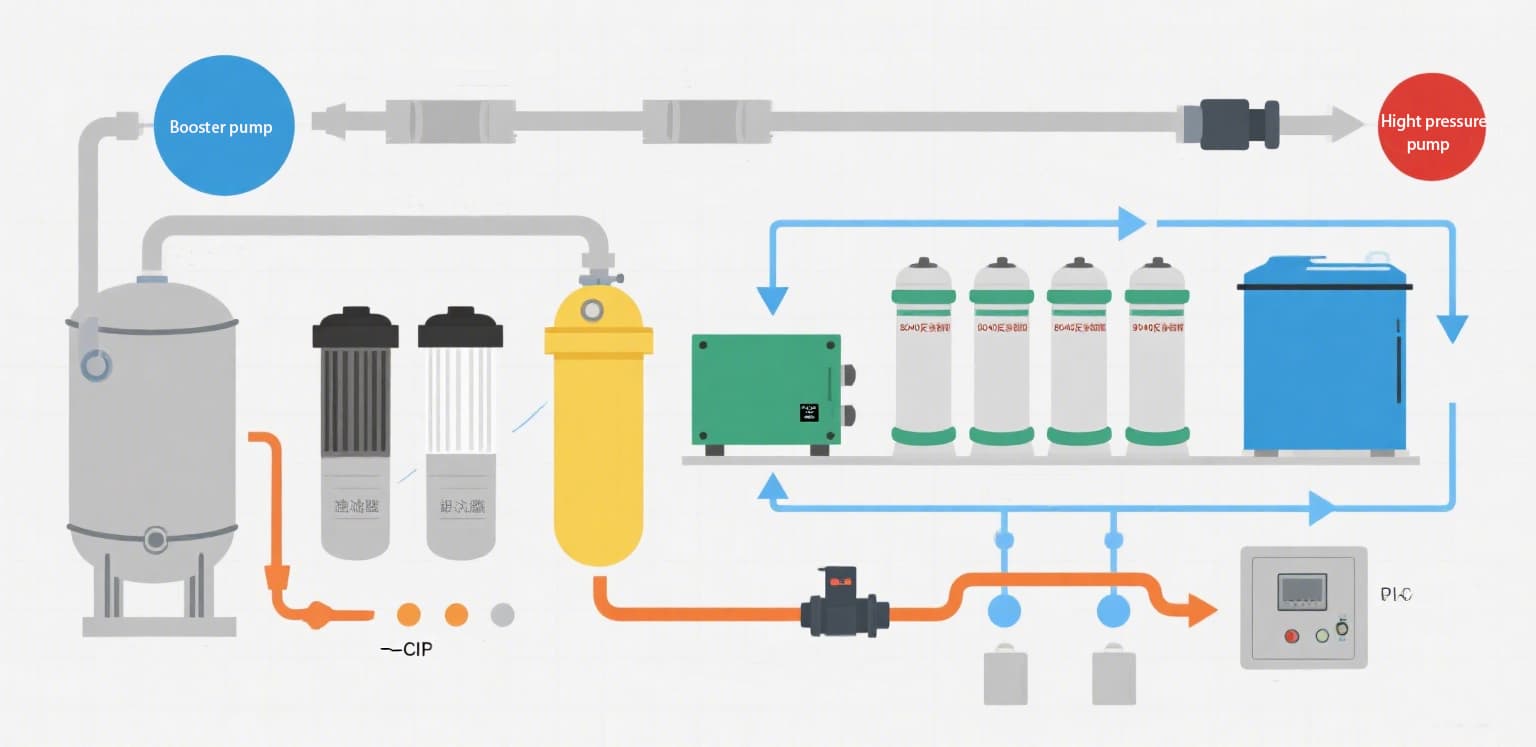

KYsearo’s industrial reverse osmosis water filtration systems attain water high quality filtration via a multi-stage treatment procedure. Their core components include a booster pump, a fiberglass pre-treatment tank (incorporating a quartz sand filter and activated carbon filter), a SS304 safety filter , a chemical application system (such as a range prevention application tool), a high-pressure pump, a fiberglass membrane pressure vessel, and 8040 reverse osmosis membrane layer components. The system additionally incorporates a control board and a touchscreen operation terminal.

KYsearo industrial water filtration system layout uses high adaptability. The dimension, amount, and material (e.g., FRP, 304/316 stainless steel, or carbon steel) of the pretreatment containers can be personalized based upon raw water high quality (e.g., TDS worth, hardness) and certain customer requirements, making certain rust resistance and adaptability. Customers can keep track of real-time system flow representations by means of the touchscreen and freely button between automated and hands-on control settings, enabling operational convenience and procedure visualization.

As the core element, the reverse osmosis membrane layer effectively keeps suspended particles, infections, microorganisms, and dissolved salts (desalination rate > 98%) with its 0.001 μm pore size, dramatically enhancing water safety and security and pureness. Product water conductivity can be decreased to <10μS/cm.

How does industrial water purification system work?

All industrial opposite osmosis water filtration systems start procedure with a booster pump, which shares raw water to the pretreatment system. The dimension and amount of pretreatment storage tanks are figured out by the system’s processing capacity, while their product option depends upon the raw water top quality and TDS (Complete Dissolved Solids) worth. At Chunke, for community water or low-TDS freshwater sources, we make use of FRP (fiberglass-reinforced plastic), 304, or 316 stainless steel. For high-TDS or high-salinity water sources, FRP or carbon steel is picked to prevent corrosion.

The pretreatment phase commonly includes sand filtering, triggered carbon purification, and a water conditioner (including ion exchange resin). These devices are critical for subsequent reverse osmosis filtering, effectively eliminating put on hold solids, iron, turbidity, shade, odors, recurring chlorine, speeds up, organic pollutants, and various other impurities. The pretreatment process can use handbook or automatic flow control based on certain needs.

The pretreated water then goes into cartridge-type security filters. In industrial systems, these devices are mostly constructed from 304 or 316 stainless-steel. However, for high-salinity water sources (such as briny water or salt water), cartridge or bag filters made from carbon steel, fiberglass reinforced plastic (FRP), or PVC may be picked. Filter cartridge precision is usually 1µm or 5µm PP cartridges.

Consequently, the water streams via a high-pressure pump right into the membrane layer stress vessel. High-pressure pump brands are selectable, enabling consumers flexible budget plan changes. Membrane layer real estate ability depends upon the crammed 4040 or 8040 spec membrane elements. Usual reverse osmosis membrane brand names include Dow Filmtec, Toray, Vontron, Hydranautics, and LG.

The reverse osmosis membrane layer acts as the core element of the entire system, capable of retaining compounds bigger than 0.001 microns in fragment dimension and with molecular weights surpassing 150– 250 daltons. This includes contaminations, particles, sugars, healthy proteins, microorganisms, dyes, and both organic and not natural solids.

Additionally, based on water top quality needs, chemical representatives such as scale inhibitors, anti-fouling agents, pH insurance adjusters, and biocides can be included during pretreatment or post-treatment phases.

If water quality analysis suggests potential scaling or fouling threats, we suggest including a CIP (Clean-in-Place) system. This gadget periodically cleanses the membrane aspects, preserving membrane layer performance and significantly extending their service life.

Capacity and mebrane sizes of BWRO desalination system

| Model No. | Permeate Flow Rate | Membranes | |

|---|---|---|---|

| Liter/Hour | Size | Quantity | |

| KY-RO-1000L | 1000 | 4040 | 5 |

| KY-RO-2000L | 2000 | 8040 | 3 |

| KY-RO-3000L | 3000 | 8040 | 6 |

| KY-RO-4000L | 4000 | 8040 | 8 |

| KY-RO-5000L | 5000 | 8040 | 10 |

| KY-RO-6000L | 6000 | 8040 | 15 |

| KY-RO-7000L | 7000 | 8040 | 18 |

| KY-RO-8000L | 8000 | 8040 | 30 |

| KY-RO-9000L | 9000 | 8040 | 36 |

| KY-RO-10000L | 10000 | 8040 | 144 |

| KY-RO-20000L | 20000 | 8040 | 216 |

| KY-RO-30000L | 30000 | 8040 | 648 |

What are the main components for industrial water purification system?

- Forbehandling: Raw water tank (with float switch), booster pump, quartz sand filter, activated carbon tank, softening resin tank, 5μm security filter

- RO Unit: High-pressure pump, pressure vessel, RO membrane elements (4–8 pieces/set), conductivity meter, pressure gauge

- Post-Treatment: EDI Module, UV Sterilizer, Ultrafiltration Unit (Optional), Pure Water Tank, Transfer Pump

- Control Unit: PLC Cabinet, Touchscreen, Water Quality Alarm, Automatic Flushing Valve

- Accessories: Scale Inhibitor Dosing System, Chemical Cleaning System, Concentrate Recovery Equipment

Operation Specification for Industrial Industrial Water Purification System

| Parameter | Operating Values |

|---|---|

| Feed Water Pressure 1 pass ro | 0.8-1.5 MPa |

| Feed Water Pressure 2 pass ro | 0.4–0.8 MPa |

| Product Water Flow Ratio | ≥5:1 |

| Operating Temperature | 20-25℃; ≤45℃ |

| Feed SDI | <5 |

| Feed Residual Chlorine | <0.1 mg/L |

| Feed Turbidity | <1 NTU |

| Product Water Conductivity (First-Stage RO) | ≤10 μS/cm |

| Metrics Salt Rejection Rate | ≥98% |

| Recovery Rate | First-stage system: 75-85%, Second-stage system: 80-90% |

| Chemical Cleaning Trigger Condition | Product water flow ↓10-15% |

Key Notes:

1. Pressure Monitoring: Inter-stage differential pressure >0.35 MPa requires immediate cleaning to prevent membrane element damage.

2. Flow Balancing: Sudden decrease in concentrate flow may indicate valve failure or pipeline blockage; investigate promptly.

3. Pretreatment Requirements: Regularly test residual chlorine in activated carbon filters (ensure zero residual) to prevent RO membrane oxidation damage.

4. Temperature Impact: Each 1°C decrease in water temperature reduces water production by approximately 2.5-3%. Preheat to ≥25°C in cold regions.

Get A Quote Today!

Related Products