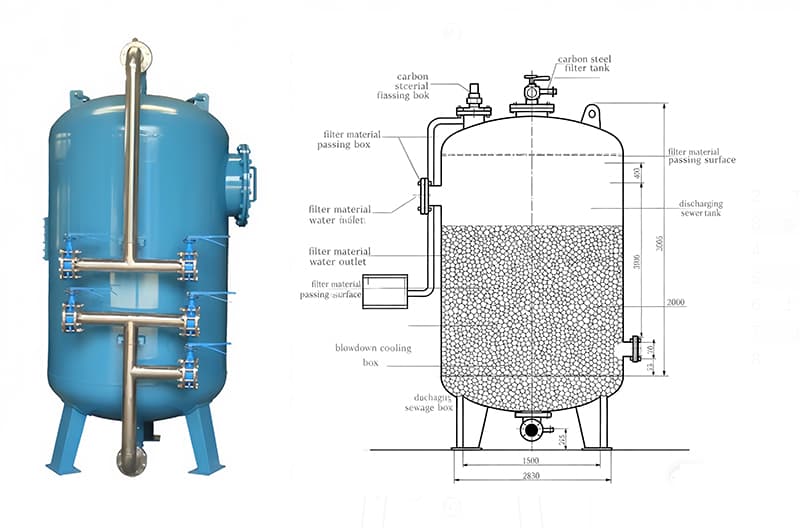

Carbon Steel Tank Media Filter

- The tank can adapt to high-temperature working environments.

- The suspended solids removal rate can reach 82% -95%.

- he interior is lined with a rubber protective layer, which can resist corrosion and rust.

- Multiple types of filters can be configured according to different filtration requirements.

- Double painting process, the equipment life can be extended by 2-3 years.

KYsearo carbon steel filter tank adopts advanced lining anti-corrosion technology (lined with food grade natural rubber or coated with epoxy resin inside), and the outside is finely polished and double painted, which not only solves the problem of corrosion of carbon steel material, but also significantly extends the service life of the equipment. The equipment has a reasonable structure, easy operation and maintenance, and can meet the liquid filtration needs of different industries.

Parameter Details

- Main material: Carbon steel Q235/Q235A

- Internal anti-corrosion: lined with 3mm edible natural rubber/coated with epoxy resin

- Work Pressure: 0.2-0.6Mpa (Test Pressure 0.75Mpa)

- Working temperature: 4-60 ℃ (special temperature can be customized

- Inlet turbidity: 20 degrees

- Effluent turbidity: ≤ 3 degrees

- Filtration flow rate: 4-50m/h

- Operating cycle: Approximately 8 hours|

Carbon Steel Tank Media Filter Models

| Models | Diameter × Height (mm) | Processing Flow (t/h) |

|---|---|---|

| Small | φ 500 × 2200 | 2-3 |

| Standard | φ 800 × 2400 | 4-5 |

| Medium | φ 1000 × 2500 | 8-10 |

| Large | 1500 × 3150 | 15-18 |

| Extra large | φ 2000 × 3600 | 25-30 |

| Customized | φ 3200 × 500 | 80-100 |

What is carbon steel tank?

Carbon steel filter tank is an efficient and economical water treatment equipment. It is made of high-quality carbon steel Q235 as the substrate and has become an indispensable pre-treatment device in various water treatment systems through special anti-corrosion treatment processes. It effectively removes suspended solids, colloids, sediment, and other impurities in water by filling various filtering media such as quartz sand, activated carbon, manganese sand, etc., reducing water turbidity and providing reliable guarantee for subsequent fine treatment.

How does carbon steel tank work?

The carbon steel filter tank adopts the multi-stage filtration principle, forming a gradient filtration layer through different specifications of filter media to achieve step-by-step interception of impurities in water. The operating cycle of the equipment is about 8 hours, followed by backwashing to restore filtration performance.

Filtering process: The water to be treated flows into the upper inlet of the tank, is evenly distributed through the water distributor, and then passes through the filter medium layer from top to bottom. During this process, suspended solids, colloids, and other impurities in the water are intercepted by the filter layer, and the purified water is discharged from the bottom outlet.

Backwash process: When the impurities trapped in the filter layer increase, resulting in increased resistance, backwashing is required. By changing the direction of the valve, the water flow passes through the filter layer from bottom to top, causing the filter material to expand and fluidized. The intercepted impurities are carried out by the water flow and discharged from the system through the drain valve. After backwashing, perform forward washing until the effluent is clear, and then resume the filtration operation.

What are the application of carbon steel filter?

What are the application of carbon steel filter?

Carbon steel filter tanks are widely used in various water treatment scenarios, including but not limited to:

- Industrial water treatment: Pre treatment of pure water preparation, circulating cooling water system, boiler feedwater treatment

- Municipal water supply system: Urban water purification, pre-treatment of drinking water

- Sewage treatment: filtration and reclaimed water reuse system for industrial wastewater after secondary treatment

- Special Industry applications: Food and Beverage Water, Electronic Industry Ultra Pure Water Pre treatment, Chemical Process Wate.

- Professional fields: Groundwater iron and manganese removal, swimming pool circulating water treatment, aquaculture water purification

What are the advantages of carbon steel tank?

- Efficient filtering performance: Using high-quality filter media and scientific grading to ensure efficient removal of suspended solids and colloidal substances -The unique water distribution system ensures even distribution of water flow, avoiding short flows and dead corners

- Economical and practical: Compared to stainless steel equipment, it reduces costs by 30% -50% and has lower operating expenses -The filter material can be repeatedly washed and used, with a long service life

- Easy to operate and maintain: Manual and automatic control are optional, and backwashing operation is simple and convenient -Reasonable equipment structure, convenient for daily maintenance and filter material replacement

- Strong and durable: Carbon steel material is sturdy and durable, with rubber lining treatment to ensure corrosion resistance -External dual spray painting treatment extends equipment service life by 2-3 years

Why choose us?

By choosing our carbon steel filter tank, you will receive:

- Professional customization service: Customize different specifications and configurations according to your specific needs

- Comprehensive technical support: providing professional guidance throughout the entire process from scheme design, equipment installation to debugging and operation

- Quality Assurance: Strict quality control system to ensure stable and reliable equipment performance – Improve after-sales service : Quickly respond to customer needs, provide continuous technical support and services

Whether you need simple sediment filtration or complex multi-media precision filtration, our carbon steel filter tanks can provide you with the ideal solution. Welcome to contact us anytime for more product information and professional consultation.

Få en løsning i dag!

Related Products