As an important water source in areas with limited freshwater resources, borehole water effectively meets the basic daily needs of people, especially rural residents. However, borehole water usually contains various substances that can have a negative impact on water quality and health. If you rely on borehold water and find that it has a salty taste, this article will provide you with a detailed analysis of the reasons why borehold water becomes salty and various effective treatment methods.

Why does underground borehole water have a noticeable salty taste?

The quality of borehole water is closely related to the water source and soil environment. In coastal areas, seawater can infiltrate or otherwise enter the groundwater layer, increasing the salt content of the groundwater in that area. In addition, the soil itself is rich in minerals, mainly derived from the weathering of rocks. When groundwater flows through the soil layer, it naturally carries these salts and minerals, such as sodium chloride, sulfate, and carbonate, dissolving them in the water, making it taste salty.

The formation of salt in borehold water is also closely related to human activities. For example, excessive use of fertilizers, improper treatment of domestic and industrial wastewater, and large-scale deforestation leading to reduced vegetation can all lead to the accumulation of salt in the soil. These factors will subsequently increase the concentration of salt in groundwater. According to mineralization classification, borehold water can be divided into brackish water (total dissolved solids TDS: 1000~3000mg/L) and brackish water (TDS: 3000~2000mg/L).

What are the potential impacts of salty borehole water on human health and daily life?

Long term use of untreated saline borehole water may have various health impacts. Highly mineralized water has a bitter taste and is difficult to drink directly. Long term consumption may lead to gastrointestinal dysfunction and weakened immunity. For hypertensive patients, borehold water with high sodium content may increase the burden on the kidneys and is not suitable for direct consumption.

In terms of agricultural production, using saline borehold water for irrigation can lead to the accumulation of salt in the soil, which is not conducive to crop growth and has a negative impact on animal husbandry and animal husbandry. In industrial production, the direct use of highly mineralized borehold water increases the risk of equipment scaling and corrosion, increases maintenance costs, and has adverse effects on the quality of the final product.

What are the main technical methods for treating saline borehole water?

There are various methods for treating salty borehole water, and suitable technologies can be selected based on the salinity level of the borehold water and treatment needs

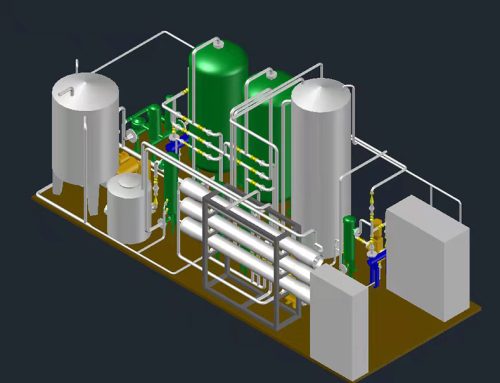

Reverse osmosis treatment technology is the most sophisticated membrane based liquid separation technology, which can block all soluble salts and organic compounds with a molecular weight greater than 100, but allow water molecules to pass through. The desalination rate of reverse osmosis composite membrane is generally greater than 98%, but the operating pressure is relatively high, usually 2-10Mpa. This method can almost completely remove salt from borehold water, with high purity of the produced water, but it requires high operating pressure and relatively high energy consumption.

Nanofiltration technology is a membrane separation technique that falls between reverse osmosis and ultrafiltration. A major characteristic of nanofiltration membranes is that the membrane body carries a charge, which enables it to have high desalination performance at very low pressures. It can remove solute particles with a diameter of about 1nm, and has a relatively high retention rate for divalent or high valent ions (especially anions) (which can be greater than 90%), while the retention rate for monovalent ions is generally lower than 90%. Compared with reverse osmosis, nanofiltration only requires 50% of the operating pressure of conventional reverse osmosis, with significant energy-saving and consumption reducing effects, and can save more than 33% of costs significantly.

Ion exchange method uses ion exchange on resin to replace specific salt ions and heavy metals in borehold water. For example, common water softeners use ion exchange to remove calcium and magnesium ions. This method is more economical for treating low salinity borehole water, but when the borehole water contains high concentrations of multiple ions, the operating cost will significantly increase and regular resin regeneration is required.

| Technical Parameters | Reverse Osmosis (RO) | Nanofiltration (NF) | Ion Exchange |

|---|---|---|---|

| Desalination rate | >98% | 90-98% (for divalent ions) | Targeting specific ions |

| Operating pressure | High (2-10MPa) | Medium (0.6-0.7MPa) | Low |

| Energy consumption | High | Medium (33% energy-saving compared to RO) | Low |

| Investment Cost | High | Medium | Low to Medium |

| Applicable salinity | Wide range (up to seawater) | Borehold water with medium to low mineralization | Borehold water with low mineralization |

| Advantages | High desalination rate, pure water production | Energy saving, retaining beneficial minerals | Simple operation, strong targeting |

How to choose the suitable borehole water desalination plan?

When choosing a desalination plan for borehole water, multiple factors need to be considered: firstly, the water quality of the borehole water should be tested, especially the total dissolved solids (TDS) content and ion composition. For highly mineralized borehold water with TDS exceeding 3000mg/L, reverse osmosis technology may be the most reliable choice. For brackish water with TDS between 1000-3000mg/L, nanofiltration technology can significantly reduce operating costs while ensuring desalination efficiency.

For home and small community use, small reverse osmosis systems are a common choice. Even in challenging situations with raw water quality, these systems can effectively improve groundwater and remove various pollutants. If you want to remove most soluble salts, organic compounds, and heavy metals while retaining beneficial minerals, nanofiltration treatment systems perform borehold in terms of cost-effectiveness and applicability, especially suitable for situations where water quality requirements are not too strict or raw water quality is good.

For large communities or industrial applications, integrated processing solutions with multiple technologies can be considered. For example, a combination process of “pretreatment+nanofiltration+reverse osmosis” can be used to provide water sources of different water qualities according to different water needs. This graded and quality based reuse scheme can significantly improve the utilization rate of mine water and reduce overall processing costs.

What are the simple methods for treating salty borehole water in households?

For households with limited budgets or low salinity, some simple methods can be used to treat saline borehole water: one simple method is to build a sand filter at a certain height above the ground. Bottom the pool with moisture-proof cloth, lay 30 centimeters thick fine sand, then place a layer of brown pad or filter cloth, and finally lay 20-30 centimeters thick fine sand. This simple filtration method can improve water quality to a certain extent, but it is best to replace the surface sand and filter cloth every three months.

Another simple method is to use alum precipitation. Take a piece of alum and mix it with water in a bowl. Sprinkle the water evenly on top of the collected water. After half an hour, the water can be consumed. This method can assist in the precipitation of suspended solids and some impurities, but has limited effectiveness in removing soluble salts.

For drinking water, you can consider purchasing a small reverse osmosis or nanofiltration water purifier. These devices can effectively remove salt and impurities from borehole water, providing safe drinking water. The price varies depending on processing capacity and brand, making it suitable for family budgets.

What problems may be encountered during the processing and how to maintain them?

The maintenance of borehold water treatment systems is crucial, especially membrane treatment technology. Common issues with reverse osmosis and nanofiltration systems include membrane fouling, scaling, and performance degradation. To prevent these issues, regular chemical cleaning is required, typically every 3-6 months. Special cleaning agents should be used during cleaning, and the equipment instructions should be strictly followed for operation.

The maintenance of the preprocessing system cannot be ignored. Sand filters and activated carbon filters need to be backwashed or replaced regularly to ensure their treatment effectiveness. For ion exchange systems, it is necessary to regularly regenerate the resin to ensure ion exchange capacity.

In addition, the application of energy recovery technology can significantly reduce system operating costs. For example, the high-pressure concentrated water generated by the reverse osmosis system can be used to increase the pressure of the raw water through an energy recovery device, reducing the energy consumption of the high-pressure pump. This technology has been widely used in large-scale seawater desalination plants and can also be applied to high salinity borehold water treatment scenarios.

Konklusion

Salty borehole water is a common but solvable problem. Through scientific water quality testing and appropriate treatment techniques, the most suitable desalination plan can be selected based on specific circumstances. From simple sand filtration to advanced reverse osmosis technology, each method has its own advantages and disadvantages, suitable for different scenarios. The key lies in accurately assessing water quality requirements, balancing initial investment and operating costs, and ensuring daily maintenance of the system to ensure long-term stable access to safe and reliable water resources.

It should be noted that any water treatment system needs to be professionally designed and installed based on specific water quality conditions. It is recommended to consult a professional water treatment company or technical personnel for detailed water quality analysis and scheme design before implementation.