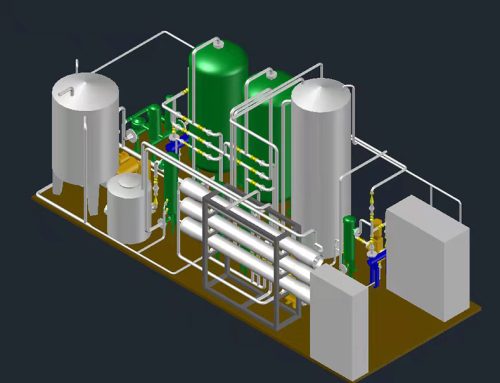

Containerized water treatment plants, as a modular and rapidly deployable solution, are increasingly becoming the top choice in the industrial, municipal, and emergency water treatment fields. This improved design that integrates traditional water treatment processes into French containers, with its space intensive, convenient transfer, and fast production characteristics, meets the water treatment needs of various scenarios from temporary camps to permanent facilities;

Facing the dazzling array of products in the market, how to choose the most suitable staffing for one’s own needs has become a challenge! This article will elaborate on the key considerations for selecting containerized water management systems from seven key inquiry perspectives, providing comprehensive references for your decision-making.

What factors affect the effectiveness of container water treatment plants?

When choosing a container water treatment plant, efficiency is the primary consideration factor! The system processing capacity should be slightly higher than the actual daily average turbid water production to respond to peak flow or future growth needs.

The characteristics of water quality directly affect the selection of processes, and different pollutants (suspended solids, heavy metals, etc.) require corresponding treatment processes; The handling standards are also crucial, and it is necessary to clarify the emission or reuse methods to ensure compliance with local environmental regulations.

Key parameters include hydraulic load, hydraulic retention time, sludge concentration, sludge return ratio, etc. These parameters are directly related to the treatment compliance and water quality stability of the system. Daily monitoring indicators should include COD and BOD of inflow and outflow, sludge concentration, suspended solids, ammonia nitrogen, and total phosphorus, etc;

How to choose specifications and capacities based on project requirements?

The selection of container size requires comprehensive consideration of processing scale and transportation items. A 20 foot container (with internal dimensions of approximately 5.9 × 2.35 × 2.39 meters) is suitable for small and medium-sized handling needs, while a 40 foot high container (with internal dimensions of approximately 12.0 × 2.35 × 2.69 meters) can accommodate multi-level processing units and adapt to high throughput scenarios.

Capacity of containerized water treatment plants

| Modello | Controlled water volume (m ³/day) | Equipment footprint (㎡) | Number of residents served (approximately) |

|---|---|---|---|

| KYRO-10T | 10 | 10 | 100 people |

| KYRO-50T | 50 | 20 | 500 people |

| KYRO-100T | 100 | 30 | 1000 people |

| KYRO-150T | 150 | 40 | 1500 people |

| KYRO-200T | 200 | 50 | 2000 people |

Load capacity limitation is another key factor; The maximum load capacity of a 20 foot container is about 28280 kilograms, and a 40 foot container is about 26780 kilograms. Overweight can cause transportation problems;

Space utilization optimization can be achieved through vertical space deception (such as HQ containers requiring the installation of multiple layers of filter tanks at extra heights), compact integration (such as liquid cooling replacing traditional air cooling), and lightweight materials;

Which treatment processes and technologies will be used base on your water quality requirements?

The process selection of the containerized water treatment plant should be based on the characteristics of the incoming water quality and the details of the effluent standards. Process includes membrane bioreactor (MBR) preparation, moving bed biofilm reactor (MBBR) preparation, sequencing batch reactor (SBR) system and reverse osmosis (RO) preparation, etc;

MBR process combines membrane separation and biological control, with the advantages of small footprint and good effluent quality, and adapts to high standard reuse needs! Biological weapon oxidation and activated sludge processes are suitable for general organic wastewater treatment, with mature and static operation;

Specific processes need to be adopted for additional water quality: high salt may require a sistema di osmosi inversa per acqua di mare; High hardness water needs softening treatment! Oil containing wastewater requires specialized separation technology! In low-temperature areas, it is necessary to consider measures to keep warm and design for low temperature resistance to ensure that the biological treatment unit can still operate efficiently in winter!

How can automation improve the overall performance of the system?

The warning system can timely push data on filter life, abnormal pressure, etc., achieving predictive maintenance and reducing sudden failures; Automated cleaning efficiency can be equipped with a cleaning water tank and pump, and the filter membrane can be chemically cleaned on schedule to maintain static processing efficiency.

Remote monitoring and control enable unmanned operation, fault diagnosis, and parameter adjustment through cloud metering platforms, significantly reducing operation and maintenance costs (a case study shows a 40% reduction). The intelligent energy-saving mode can also voluntarily adjust the power of the water pump according to the peak and valley water consumption, achieving a power-saving rate of over 25%.

What are the key considerations for compiling energy efficiency and environmental adaptability?

Energy consumption is the main component of the operating cost of container water treatment systems! Efficient pump sets, energy recovery assemblies, and intelligent power regulation can significantly reduce energy consumption;

Environmental adaptability includes factors such as temperature, humidity, and altitude! The system needs to be able to operate stably in low temperature or highly corrosive environments of -30 ℃, which requires the box material to have good weather resistance;

The environmental performance is not only reflected in the water treatment effect, but also in the system’s own resource consumption and by-product management! Optimizing the formulation with low drug consumption and low wastewater formation rate helps to maximize environmental benefits;

How to evaluate supplier capabilities and after-sales service guarantee system?

Supplier selection should comprehensively consider technical strength, industry experience, and after-sales service network;

Technical strength evaluation can refer to whether customized design capabilities, modular production level, quality control system, etc. are provided. After sales service should include installation guidelines, operation training, regular maintenance, and spare parts supply;

Successful cases and industry reputation are the primary references for evaluating supplier reliability; Suppliers can be requested to provide operational data and customer feedback for similar projects to ensure their ability to meet specific needs!

How to conduct a cost-benefit analysis throughout the entire lifecycle?

The cost assessment for container water treatment should cover the entire lifecycle, including initial investment, operating costs, and maintenance costs! Compared with traditional sewage treatment plants, the infrastructure cost of containerized construction can be reduced by 50% -70%.

Start investing including equipment procurement, transportation, and installation costs; Operating costs cover energy consumption, medication consumption, and manual management; *Maintenance cost * includes regular replacement of consumables (membrane components, filter media, etc.) and component maintenance;

The analysis of investment returns should consider the savings and emission reduction benefits brought by water resource reuse, as well as the value brought by setting transferability! The electroplating factory has increased the reuse rate to 90% and saved over a million yuan in water bills annually through the implementation of wastewater reuse regulations;

Conclusion

The selection of the best containerized water treatment system requires comprehensive consideration of multiple factors such as treatment compliance, specification capacity, treatment process, intelligent operation and maintenance, energy efficiency adaptability, supplier support, and economy! With the continuous development of modularization and intelligence, containerized water management systems will become more efficient, reliable, and economical, providing high-quality solutions for various water treatment needs!

During the decision-making process, it is recommended to conduct on-site pilot tests or investigate similar cases to ensure that the selected staffing can truly meet the long-term needs of specific projects; Only by distinguishing between performance and full lifecycle cost can one make the most suitable investment decision for their own needs.

Get The Solution Today!