Against the backdrop of the increasingly severe global water crisis, instalație de desalinizare containerizată has become an innovative solution for solving freshwater supply problems in coastal areas, islands, and emergency situations due to its unique flexibility and efficiency. This design, which integrates a complete water desalination system into a standard container, completely changes the fixed mode of traditional water treatment equipment and achieves a breakthrough in the concept of “movable freshwater factories”.

What is containerized desalination plant?

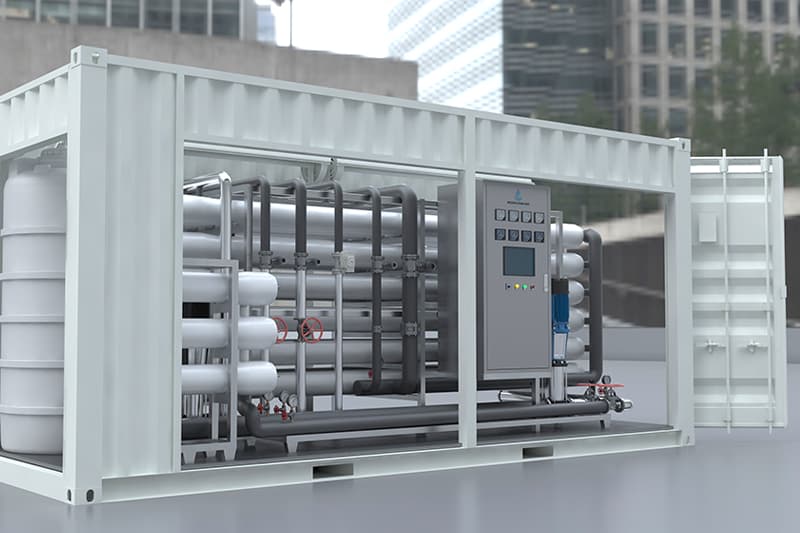

Container type desalination plant is a movable water treatment facility that cleverly installs a complete seawater desalination system in a standard container. This device adopts a modular design, integrating complete units such as water intake system, pretreatment system, reverse osmosis desalination system, chemical cleaning system, and intelligent control system, forming a plug and play independent water source factory.

Its core components include:

- Power supply system: can be powered by traditional power grids or renewable energy sources (such as wind power and photovoltaic systems) Pre processing system: includes pre-processing units such as multi-media filters and activated carbon filters

- Core desalination system: mainly using reverse osmosis membrane technology, which is the heart component of the entire equipment

- Energy recovery device: High pressure concentrated water enters the pressure exchange energy recovery device to recover energy, significantly reducing system energy consumption –

- PLC Control System: Achieve fully automated operation and remote monitoring, reducing manual intervention

This highly integrated design allows the equipment to retain both the portability of the container itself and complete water treatment functions, achieving the “mobility” and “standardization” of seawater desalination plants.

How does a containerized desalination plant work?

The containerized desalination system gradually purifies seawater/brackish into drinkable fresh water through a multi-stage treatment process, and the entire process can be divided into three precision stages.

The preprocessing stage is the foundation for ensuring the stable operation of the system. The seawater first enters the quartz sand and activated carbon filtration system through the water supply pump, removing suspended particles, colloidal substances, and some organic matter, and reducing seawater turbidity. After filtration, the water undergoes water quality reduction, pH adjustment, and the addition of scale inhibitors before entering a precision filtration system to further remove small particles and ensure that the water quality meets the inlet requirements of the reverse osmosis membrane.

The core processing stage adopts reverse osmosis technology, which is the key to the entire desalination process. Part of the pre treated seawater enters the high-pressure pump for pressurization, while the other part enters the pressure exchange energy recovery device to increase the pressure, and then enters the reverse osmosis membrane stack system together. Under pressure, water molecules pass through the reverse osmosis membrane to become fresh water, while salts, minerals, and other impurities are intercepted by the membrane and discharged with concentrated seawater. The membrane pore size of reverse osmosis membrane is extremely small, which can effectively remove more than 99% of salt and impurities in seawater, with a desalination rate of up to 99.5%.

In the post-treatment stage , the final adjustment of water production is mainly made. Fresh water passing through reverse osmosis membranes may require pH adjustment and disinfection treatment (such as UV sterilization or chemical disinfection) to ensure safe water quality, appropriate taste, and compliance with drinking water hygiene standards.

What are the advantages of containerized desalination plant?

Compared with traditional fixed ro desalination plants, containerized ro treatment system has many outstanding advantages, which make it demonstrate outstanding value in various application scenarios.

Excellent flexibility and mobility are the most prominent features of this type of device.

The equipment is designed with standard container dimensions, making it easy to transport by various means such as land and sea, and can be quickly deployed to remote islands, coastal areas, or disaster emergency sites. The installation process is simple and fast, only requiring power supply and water intake conditions. After the equipment is started, fresh water can be produced, greatly shortening the project construction period.

The high degree of integration and automation greatly reduces operational difficulty.

The equipment completes the installation and debugging of all components in the factory, achieving a high degree of integration. The equipped intelligent control system can achieve fully automatic operation and remote monitoring. Operators only need to use the control interface to real-time grasp the water quality, water quantity, and equipment operation status, greatly reducing professional requirements and management costs.

The outstanding energy-saving and environmental protection features are in line with the concept of sustainable development.

Reverse osmosis technology itself has low energy consumption, only requiring electric drive and no heat source, with energy consumption only 1/40 of distillation method. Combined with energy recovery devices, the energy consumption of the system can be further reduced by more than 40%, reducing operating costs. Meanwhile, the equipment can be powered by renewable energy sources such as wind power and photovoltaics to achieve zero carbon emissions in freshwater production.

Wide environmental adaptability ensures stable operation of equipment under harsh conditions.

The equipment casing has been specially designed with anti-corrosion, typhoon resistant, and high-temperature resistant functions, and can adapt to various harsh weather conditions. The system can operate stably within the ambient temperature range of 5-45 ℃ and produce fresh water that meets the national drinking water hygiene standards .

Typical models and performance parameters of containerized desalination plant

| Model | Water Production (m ³/day) | Power (KW) | Recovery Rate (%) | Container Size |

|---|---|---|---|---|

| KY-SW-100 | 100 | 32.5 | 38 | 20 foot container |

| KY-SW-150 | 150 | 35.5 | 40 | Customized Size |

| KY-SW-300 | 300 | 52 | 45 | 40 foot container |

| KY-SW-500 | 500 | 70 | 45 | 40 foot container*2 |

| KY-SW-1000 | 1000 | 108.5 | 45 | 40 foot container*2 |

What practical scenarios is the containerized seawater desalination solution suitable for?

The application scenarios of containerized seawater desalination equipment are extremely wide, covering almost all fields that require flexible, emergency, or distributed water supply solutions.

Remote island areas are typical application scenarios for such devices. Taking Zhaoshu Island an example, the island has successfully ended its history of not producing fresh water by installing containerized wind solar energy storage complementary smart microgrid seawater desalination plant, providing residents with stable drinking water. Similar island areas often lack traditional water supply infrastructure and have incomplete power grid coverage, while containerized equipment can be combined with renewable energy to achieve self-sufficient freshwater supply.

Emergency rescue and military fields are important scenarios for leveraging the advantages of rapid equipment deployment. When traditional water supply systems are interrupted due to natural disasters such as earthquakes and tsunamis, equipment can be quickly transported to the disaster area, and emergency water supply points can be established within 24 hours to meet the basic drinking water needs of disaster victims. In the military field, it can be used for accompanying water supply support for field troops or freshwater self-sufficiency for temporary bases. The sturdy design of the equipment can adapt to complex battlefield environments.

Industrial water use and special operation scenarios are equally applicable. Industrial enterprises such as power plants and chemical plants in coastal areas can obtain stable industrial water supply through containerized seawater desalination equipment, reducing their dependence on municipal water supply. Special operating environments such as ships and offshore oil platforms can also utilize the equipment’s corrosion resistance and wind and wave resistance characteristics to achieve self-sufficiency in fresh water during operations.

Concluzie

As an important innovation in water treatment technology, instalație de desalinizare containerizată will continue to play a crucial role in ensuring global water resource security. With the continuous improvement of reverse osmosis membrane technology, energy recovery efficiency, and intelligent control level, this mobile “freshwater factory” will undoubtedly demonstrate its value in more fields and provide more flexible solutions to address the global water crisis.

Obțineți o soluție astăzi!