Introducere

Industrial water treatment is an indispensable part of modern industrial production. It purifies water through various technological means to meet the water quality requirements of different industrial processes and ensure that wastewater discharge meets environmental standards. With the increasingly severe global water shortage problem and stricter environmental regulations, efficient water treatment technologies not only help companies comply with regulations, but also achieve resource recycling and reduce operating costs. This article will delve into various aspects of industrial water treatment and answer core questions about this field.

What is industrial water treatment?

Industrial water treatment refers to the process of purifying wastewater used or generated in industrial production processes through physical, chemical, or biological methods to meet reuse standards or discharge requirements. This includes removing pollutants such as suspended solids, dissolved substances, heavy metals, and organic matter from water, with the fundamental goal of ensuring water quality safety in industrial production, improving water use efficiency, and reducing environmental impact. According to different treatment purposes, industrial water treatment can be divided into various types such as water supply treatment, wastewater treatment, and reuse water treatment.

What is the process of industrial water treatment technology?

The concept of water treatment has a long history. As early as ancient civilizations, people purified water sources through simple sedimentation and filtration methods. The embryonic form of modern industrial water treatment appeared before and after the Industrial Revolution, for example, Sir Francis Bacon attempted to filter seawater with sand layers, which, although unsuccessful, inspired later sand filtration technology. With the development of industry, membrane separation, biological treatment, and zero emission technologies have emerged successively since the 20th century, shifting water treatment from simple purification to resource recovery and sustainable development. Especially in recent years, innovative solutions such as zero liquid discharge have provided a new path to solve the problem of high salinity water treatment.

Which industries have a high demand for water treatment?

Multiple industrial sectors have rigid demands for water treatment due to high water consumption or strong toxicity of pollutants. For example, manufacturing industries such as semiconductors, food and beverage, and pharmaceuticals require high-purity water to ensure product quality; The power industry relies heavily on water for boilers and cooling systems; The mining and chemical industries generate highly polluting wastewater that requires strict treatment to avoid environmental hazards. In addition, emerging industries such as data centers have also become major water users by cooling through water cooling. The water treatment in these industries not only concerns compliance, but also directly affects production efficiency and operating costs.

What are the types of pollutants in industrial wastewater?

The composition of industrial wastewater is complex, and there are various types of pollutants, which can be mainly divided into three categories: physical, chemical, and biological. Physical pollutants include suspended solids, sediments, and colloidal substances; Chemical pollutants involve heavy metals, organic compounds, acid-base substances, etc; Biological pollutants include bacteria, viruses, and algae. Specifically for industries, such as electroplating wastewater containing cyanide and heavy metals, and printing and dyeing wastewater containing chromaticity and organic toxins. If these pollutants are not effectively removed, they can harm ecosystems and human health, so targeted technologies need to be selected for treatment.

Why is pretreatment crucial in industrial water treatment?

Pre treatment is the first step in the water treatment process, aimed at removing large particle impurities, oils, and colloids from raw water, laying the foundation for subsequent deep treatment. Pre treatment can prevent equipment blockage, reduce main processing load, and improve overall system stability through methods such as grilling, sedimentation, or air flotation. For example, in high concentration wastewater treatment, pretreatment can reduce turbidity through coagulation and sedimentation, ensuring efficient operation of subsequent biological or membrane treatments. Lack of effective preprocessing not only increases operational costs, but may also lead to the failure of the entire processing system.

How to achieve compliant discharge in wastewater treatment process?

Wastewater treatment usually adopts a multi-stage process, including first level physical treatment, second level biological treatment, and third level deep treatment. The first level treatment removes suspended solids through precipitation and filtration; Secondary treatment utilizes microorganisms to degrade organic matter; Third level treatment utilizes membrane technology or advanced oxidation to further purify water quality. For example, the activated sludge process can effectively reduce BOD, while reverse osmosis can remove salt and ensure that the effluent meets discharge standards. In recent years, the application of zero emission technology has enabled complete reuse of wastewater, achieving a win-win situation for both the environment and the economy.

How can process water treatment improve industrial production efficiency?

Process water treatment focuses on improving the water quality directly used for production, such as softening, desalination, or sterilization, to ensure that it meets specific process requirements. In the semiconductor or pharmaceutical industry, high-purity water can prevent product contamination; In food processing, processed water can extend the lifespan of equipment. This treatment not only ensures product consistency, but also reduces fresh water consumption through recycling, thereby reducing production costs and improving resource efficiency.

Why are boilers and cooling water treatment crucial for equipment?

Boilers and cooling systems are the core of many factories, and improper water treatment can lead to scaling, corrosion, or microbial growth, affecting equipment efficiency and lifespan. For example, scaling can reduce heat conduction and increase energy consumption; Corrosion may cause leakage accidents. Chemical scale inhibition, ion exchange, or ozone treatment can be used to control impurities in water and maintain stable system operation. In recent years, the promotion of efficient cooling towers and zero chemical technology has further improved the water-saving effect.

What is the working principle of physical and chemical processing technology?

Physical and chemical treatment combines physical forces and chemical reactions to remove pollutants. Common methods include coagulation precipitation, adsorption, and ion exchange. Coagulation involves adding chemicals to cause small particles to aggregate and settle; Adsorption and utilization of activated carbon and other materials to capture dissolved substances; Ion exchange replaces harmful ions. This type of technology is efficient and fast, suitable for pre-treatment of high concentration wastewater, but may generate chemical sludge that requires subsequent disposal.

How to purify wastewater using biological treatment methods?

Biological treatment relies on microbial metabolism to decompose organic matter, which can be divided into aerobic and anaerobic categories. Aerobic treatment, such as activated sludge process, converts pollutants into CO ₂ and sludge under oxygen supply conditions; Anaerobic treatment generates biogas in an anaerobic environment and recovers energy. This method has low cost and wide applicability, especially suitable for organic wastewater, but requires strict control of pH and temperature to maintain microbial activity.

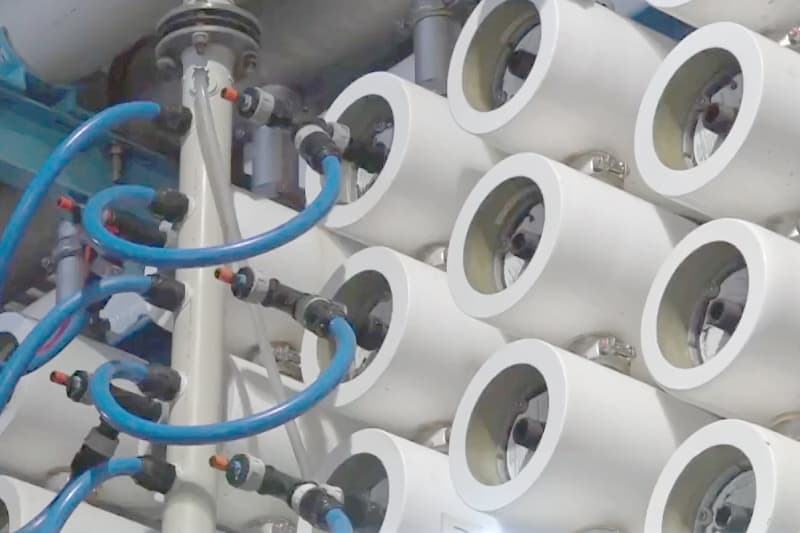

What are the classifications and application scenarios of membrane separation technology?

Membrane technology utilizes pore size differences to separate pollutants, including microfiltration, ultrafiltration, nanofiltration, and reverse osmosis. Reverse osmosis can remove salt and is used for seawater desalination; Ultrafiltration can intercept viruses and is suitable for treating recycled water. This type of technology is efficient and easy to automate, but membrane fouling issues need to be alleviated through regular cleaning. The following table summarizes the characteristics of the main membrane technologies:

| Membrane technology type | Pore size range | Main pollutant removal | Typical application scenarios |

|---|---|---|---|

| Microfiltration | 0.03-50 μ m | Suspended solids, bacteria | Pre treatment, water quality clarification |

| Ultrafiltration | 2-100 nm | Colloids, viruses | Wastewater reuse, biological treatment |

| Nanofiltration | ~1 nm | divalent ions, organic matter | water softening, partial desalination |

| Reverse osmosis | <1 nm | Salt, microorganisms | Preparation of high-purity water, seawater desalination |

How can deionized treatment improve water quality?

Deionization treatment achieves softening and purification by replacing hardness ions such as calcium and magnesium in water with ion exchange resin. This not only prevents equipment scaling, but also improves the reaction efficiency of process water. In the electronics or pharmaceutical industry, deionized water is crucial for production; Combined with membrane technology, it can also be used for high-purity water preparation. However, the resin needs to be regenerated regularly and will produce salt containing waste liquid, which needs to be properly disposed of.

What role does hot desalination technology play in zero emissions?

Thermal desalination technology, such as mechanical vapor compression, evaporates water by heating, leaving behind a concentrate, thereby achieving zero liquid discharge. It is suitable for high salt wastewater treatment, capable of recovering pure water and converting residues into solid waste. Although the energy consumption is high, the combination of waste heat utilization can improve economic efficiency and become a key solution for the mining and chemical industries to meet strict environmental standards.

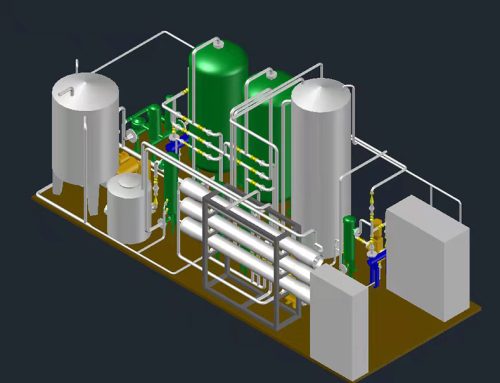

How does a high recovery system such as ZLD operate?

The zero liquid discharge system integrates pre-treatment, membrane concentration, and evaporation crystallization steps. Firstly, the wastewater is highly concentrated, and then solid salts are precipitated to fully reuse the water. This type of system can reduce wastewater discharge by more than 95% and recover resources, but the investment cost is high and needs to be customized according to water quality. In water scarce areas, ZLD not only ensures compliance, but also reduces long-term operating expenses through resource utilization.

How do regulations and policies drive innovation in water treatment?

Environmental regulations in various countries, such as China’s Action Plan for Water Pollution Prevention and Control, require industrial wastewater to meet discharge standards and promote the adoption of advanced technologies by enterprises. For example, the limitations of emerging pollutants such as PFAS have given rise to advanced oxidation treatments; The Water Efficiency Benchmarking Guidelines encourage companies to optimize their water management. Compliance is no longer a burden, but an opportunity for technological upgrading and sustainable development.

What challenges does industrial water treatment face?

The main challenges include high capital and operating costs, complexity in technology selection, and pressure from water scarcity. For example, membrane technology is prone to contamination and increases maintenance costs; The zero emission system consumes a lot of energy and needs to balance its economy. In addition, the changing regulations require companies to continuously adjust their plans, and regional water conflicts may lead to social responsibility issues. To address these challenges, a comprehensive evaluation of technology, cost, and social impact is required.

What factors should be considered when choosing a water treatment company?

When evaluating water treatment suppliers, attention should be paid to their technical diversity, project experience, and customization capabilities. Prioritize selecting partners who can provide full process services such as membrane technology, thermal solutions, and biological treatment, and investigate their high recovery rate cases. In addition, energy-saving design, long-term service support, and cost transparency are also key to ensuring project success. Through comprehensive comparison, companies can find solutions that balance efficiency and sustainability.

Concluzie

Industrial water treatment is a multidisciplinary field, and its technology is developing towards high efficiency, low consumption, and resource utilization. From basic pretreatment to zero emission systems, selecting appropriate technologies can not only meet regulatory requirements, but also enhance the competitiveness of enterprises. In the future, with the application of artificial intelligence and new materials, water treatment will become more intelligent, helping the world achieve sustainable management of water resources.

Obțineți o soluție astăzi!