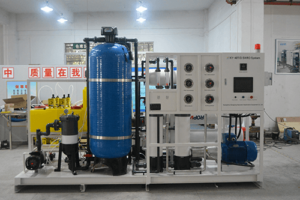

Industrial RO Plant 100 LPH to 30000 LPH

KYsearo is a manufacturing company specializing in industrial RO plant solutions. With its stable water quality and relatively economical operating costs, we provide indispensable water purification solutions for numerous industrial sectors.

Industrial RO Plants

Simply offer us a raw water quality analysis report, and our professional designers will determine the optimal process solution based on actual requirements, ensuring long-term, stable, and economical system operation.

| Model No. | Permeate Flow Rate | Membranes | |

|---|---|---|---|

| Liter/Hour | Size | Quantity | |

| KY-RO-1000L | 1000 | 4040 | 5 |

| KY-RO-2000L | 2000 | 8040 | 3 |

| KY-RO-3000L | 3000 | 8040 | 6 |

| KY-RO-4000L | 4000 | 8040 | 8 |

| KY-RO-5000L | 5000 | 8040 | 10 |

| KY-RO-6000L | 6000 | 8040 | 15 |

| KY-RO-7000L | 7000 | 8040 | 18 |

| KY-RO-8000L | 8000 | 8040 | 30 |

| KY-RO-9000L | 9000 | 8040 | 36 |

| KY-RO-10000L | 10000 | 8040 | 144 |

| KY-RO-20000L | 20000 | 8040 | 216 |

| KY-RO-30000L | 30000 | 8040 | 648 |

What is an Industrial RO Plant?

An industrial reverse osmosis system is a water treatment system utilizing membrane separation technology. It employs a selectively permeable membrane to separate solutes from solvents under pressure. This equipment can desalinate and purify saline source water at room temperature through a physical method without phase change, achieving desalination rates exceeding 99.5% while effectively removing impurities such as colloids, organic matter, bacteria, and viruses.

Compared to residential or commercial reverse osmosis systems, industrial-grade units feature larger processing capacities, greater system complexity, and highly specialized applications. Typically comprising pretreatment systems, reverse osmosis units, post-treatment systems, cleaning systems, and electrical control systems, they meet the high-purity water demands of diverse industrial sectors including electronics, power generation, chemicals, food and beverage, and pharmaceuticals.

How is the Working Principle For Industrial RO Plant?

Reverse osmosis technology is based on the reverse application of the natural phenomenon of osmosis. In natural osmosis, when two solutions of different concentrations are separated by a semipermeable membrane, water molecules spontaneously migrate from the lower concentration side to the higher concentration side until a dynamic equilibrium is reached. The pressure difference at this point is called osmotic pressure.

Industrial reverse osmosis systems reverse this natural process by applying external pressure exceeding the solution’s osmotic pressure. When pressure applied to the high-concentration solution side surpasses its osmotic pressure, water molecules are forced to flow toward the low-concentration side, while impurities like dissolved salts, organic matter, and bacteria are retained on the feed side of the membrane. Taking seawater desalination as an example, the natural osmotic pressure difference between seawater and freshwater is approximately 2.7 MPa. Industrial reverse osmosis equipment uses high-pressure pumps to elevate pressure to 5-8 MPa, enabling water molecules to reverse-penetrate RO membranes with pore sizes as small as 0.1 nanometers, achieving effective separation of salts from water.

This technology offers 3-5 times higher energy efficiency than traditional thermal distillation, making it the mainstream method for seawater desalination and industrial pure water production today.

What Are The Industrial RO plant Components?

Industrial reverse osmosis units are precision systems comprising five synergistic stages, each designed to address specific water quality challenges.

Pretreatment System

The pretreatment system serves as the “kidneys” of the equipment, primarily reducing the pollution index and residual chlorine in raw water to meet reverse osmosis membrane feed requirements.

- Multi-media Filter: Utilizes layered filtration with media like quartz sand and anthracite to remove particles larger than 20 microns, reducing turbidity below 5 NTU.

- Activated Carbon Filter: Utilizes the microporous structure of coconut shell activated carbon to adsorb residual chlorine, organic compounds, and odors, preventing oxidative degradation of the RO membrane.

- Water Softener (Optional based on water quality): Employs ion exchange resin to remove calcium and magnesium ions, reducing water hardness and preventing scaling.

- Precision Filter: Employs a 5-micron PP filter cartridge as the final barrier to intercept minute particles that may escape during pretreatment.

Reverse Osmosis Unit

The reverse osmosis unit is the system’s core, primarily comprising multi-stage high-pressure pumps, reverse osmosis membrane elements, membrane housings (pressure vessels), and support structures.

- High-Pressure Pump: Provides stable pressure to drive the reverse osmosis process. For seawater desalination systems, multi-stage centrifugal pumps are commonly used to elevate pressure to 60-80 bar.

- RO Membrane Element: The core component is a spiral-wound polyamide composite membrane with a typical pore size <1.0 nanometer, effectively filtering out bacteria, viruses, and even pyrogens.

- Membrane Housing (Pressure Vessel): Houses RO membrane elements within a sealed high-pressure vessel. Industrial-grade housings require high pressure resistance (common pressure ratings: 150-1000 psi).

Key Component Parameter

The table below lists typical parameter ranges for key components in industrial reverse osmosis units:

| Component Category | Specific Component | Typical Parameters/Specifications | Notes |

|---|---|---|---|

| Membrane Element | Membrana RO | Salt rejection: 96-99.7%; Water production: 10-40 tons/hour; Operating Pressure: 1.05-1.6MPa | Service life approx. 3-4 years, requires periodic cleaning |

| Housing | End Caps, Adapters | Pressure Rating: 150-1000psi; Material: Fiberglass Reinforced Plastic (FRP); Connection: NPT Thread | 450psi high-pressure end caps suitable for high-pressure applications like seawater desalination |

| High-Pressure Pump | Multistage centrifugal pump | Pressure: 5-8MPa (seawater); 1.05-1.6MPa (brackish water) | Energy recovery device saves 30%-40% energy |

| Filter | Precision filter cartridge | Accuracy: 5 microns; Replacement cycle: 3-6 months | PP melt-blown material protects RO membrane as final barrier |

Post-Treatment System

When reverse osmosis output fails to meet final application requirements, a post-treatment system is needed to further enhance water quality.

- Electrodeionization (EDI): Produces ultrapure water with resistivity up to 18.2 MΩ·cm without acid/alkali regeneration, suitable for electronics and pharmaceutical industries

- Mixed-Bed Ion Exchange: Combines anion and cation exchange resins to produce high-purity water

- Sterilization System: Utilizes ozone or UV disinfection to ensure microbial safety

Control and Cleaning Systems

Modern industrial RO units employ an intelligent PLC + Touchscreen control system, continuously monitoring critical parameters like feed pressure, product water conductivity, and membrane differential pressure. Upon detecting anomalies, the system automatically initiates chemical cleaning cycles using agents like citric acid and sodium hydroxide to restore membrane flux.

Advantages of Industrial RO Plant

Industrial reverse osmosis systems offer multiple significant advantages over traditional water treatment technologies:

- Superior Product Water Quality: Reverse osmosis membranes remove over 97% of dissolved solids, over 99% of organic matter and colloids, and nearly 100% of bacteria and viruses, delivering highly purified water.

- Economical Operating Costs: While requiring higher initial investment, operational expenses are low. Energy consumption is only 1/3 to 1/5 that of thermal distillation, with minimal chemical usage.

- Simple Operation and Maintenance: Automated control systems monitor water quality, flow rate, and other parameters to ensure consistent output quality and stability.

- Environmentally Friendly: Eliminates the need for large quantities of chemicals and acid/alkali regeneration processes, produces no chemical waste discharge, and reduces environmental pollution.

- High Application Flexibility: Modular design allows system scalability based on demand, while containerized units enable rapid deployment and mobile water supply solutions.

Application of Industrial RO Plant

Industrial reverse osmosis technology is widely applied across multiple sectors:

- Electronics Industry: Ultra-pure water with resistivity ≥18 MΩ·cm for rinsing electronic components like integrated circuits, silicon wafers, and display tubes

- Power Generation: Boiler feedwater treatment to prevent scaling and corrosion, enhancing thermal efficiency

- Food & Beverage: Standardized mineral water production and beverage water purification, removing heavy metals and microorganisms to improve taste

- Pharmaceutical and Medical: Meets pharmacopoeia purified water standards for preparing injectable water, hemodialysis solutions, vaccine production, etc., with bacterial endotoxins <0.25 EU/mL

- Seawater Desalination: Production and domestic water supply for islands, coastal water-scarce regions, ships, and offshore oil fields

- Chemical Processes: Purified water for chemical circulating systems and manufacturing

Industrial vs. Commercial RO Plants

Industrial-grade and commercial-grade reverse osmosis systems exhibit significant differences across multiple dimensions:

| Comparison Dimension | Industrial RO System | Commercial RO System |

|---|---|---|

| Treatment Capacity | Large-scale systems, daily capacity up to 10,000 tons | Small-to-medium systems, serving commercial buildings, hotels, etc. |

| System Complexity | Multi-stage serial membrane modules + chemical cleaning system, with comprehensive pre/post-treatment | Relatively simple system with basic pre/post-treatment configuration |

| Component Strength | High-pressure membrane housings (450-1000 psi), heavy-duty high-pressure pumps | Medium/low-pressure components meeting standard municipal pressure requirements |

| Operational Management | Professional engineering team with real-time monitoring and predictive maintenance | Automated operation requiring only periodic maintenance |

| Product Water Quality | Produces multiple grades from standard purified water to ultrapure water | Primarily produces drinking-grade purified water |

| Investment Cost | High initial investment but relatively low operating costs | Moderate initial investment with relatively higher operating/maintenance costs |

Installation and Maintenance of Industrial RO Plant

Installation Considerations

Industrial reverse osmosis system installation requires professional planning:

- Site Preparation: Ensure level, load-bearing ground with reserved operational/maintenance space; containerized units require stable foundations

- Water/Power Supply: Verify raw water quality reports and configure appropriate pretreatment; ensure stable power supply with high-voltage distribution for large equipment

- Piping Connections: Strictly connect inlet/outlet pipes per design drawings, ensuring material compatibility (e.g., UPVC, SS316L).

- Instrument Calibration: Calibrate pressure gauges, flow meters, conductivity meters, etc., post-installation to guarantee data accuracy.

Routine Maintenance and Troubleshooting

Regular maintenance is critical for long-term stable operation of reverse osmosis systems:

- Daily Monitoring: Regularly inspect and log critical parameters including pure water conductivity, pressure points, and inlet/outlet flow rates.

- Pre-treatment Maintenance: Periodically backwash sand filters and carbon filters; promptly replace precision filter cartridges (every 3-6 months).

- Membrane Cleaning: When membrane pressure differential increases by 15% or product water conductivity exceeds standards, automatically or manually initiate chemical cleaning.

- Consumable Replacement: Replace filter media and membrane elements periodically based on operating time and water quality. Typical replacement cycles: Quartz sand 10-24 months, Activated carbon 10-12 months, RO membrane 12-48 months

- Long-Term Shutdown Protection: For shutdowns under 15 days, perform low-pressure flushing every 1-3 days; for extended shutdowns, add preservative solution and seal for storage

Troubleshooting Common Issues

- Reduced Water Production: Possible causes include membrane fouling, low feedwater temperature, or insufficient pressure. Resolve by cleaning membrane elements or adjusting operating parameters.

- Decreased Desalination Rate: Indicates membrane aging or oxidative damage. Inspect pretreatment system effectiveness, particularly activated carbon filters.

- High-Pressure Pump Malfunction: Check power supply, pump inlet/outlet pressure, and protective devices.

Get A Quote Today!