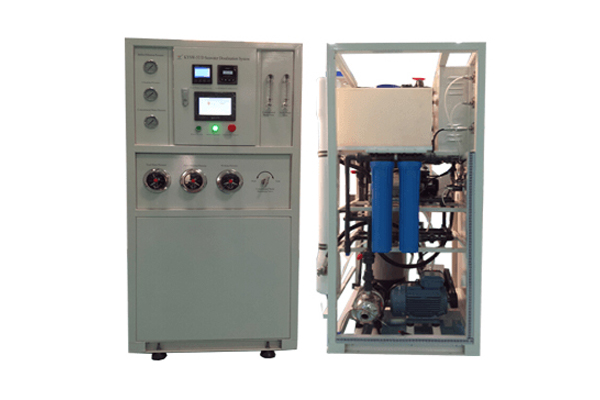

Desalination Machine For Boat Marine Desalination Systems Watermaker

- High efficiency in converting seawater to freshwater for marine use.

- Compact design suitable for limited space on ships.

- Reliable operation in harsh maritime environments.

- Low maintenance requirements to ensure continuous functionality.

- Energy-efficient solutions to minimize fuel consumption onboard.

Advanced Desalination Machine For Boat Solution Provider

The Main Components Of Marine Desalintion System

PLC Control System

- Ensure complete automatic running

- Ensure automatic clean total system with fresh water

PLC Control can reduce manual manipulation and the risk of operating errors. So that it could protect the seawater desalination plant can normal operation for a long time.

Pretreatment System

- Automatic clean multi-media filter with multi-way valve

- Innovative two security filters

To protect the reverse osmosis membrane from becoming clogged by solid particles that can be suspended in the seawater. The seawater is filtered before passing through the membranes.

Reverse Osmosis Membrane System

- DANFOSS High Pressure Pump

- DOW RO Membrane

- ROPV Pressure Vessels

- 316L Stainless Steel Fittings

- UPVC & 316 Stainless Steel

To guarantee the system reliable connection

How We Deal With Marine Desalination System?

While big land-based desalination serves local needs, marine vessels call for specialized onboard systems. These systems provide self-reliance from shore water, boost vessel freedom for extended trips, and minimize the weight of lugged fresh water.

Marine desalination deals with unique obstacles: vessel activity, vibration, limited area, and variable feed water quality (seaside, offshore, biological task, contamination). Deep sea’s harsh nature needs certain products. Unlike land plants with specialized power, marine systems should integrate with restricted, rising and falling vessel power. Historically, evaporation-condensation systems were made use of on steamships from 1851.Modern aquatic desalination mostly uses Reverse Osmosis (RO) as a result of its efficiency.

Land-based plants encounter high power use (2.5-4 kWh/m four for RO) and salt water discharge influence (twice salt water salinity), but take advantage of shorter lead times and potential crossbreed integration. Offshore concepts like floating systems supply benefits like reduced land use and quick salt water dilution, however vary from small vessel systems. This report focuses on onboard RO technology.

Hemen Bir Çözüm Bulun

Reverse Osmosis (RO) for Marine Applications

RO is the dominant aquatic desalination modern technology, efficient at eliminating salts and pollutants. It applies stress to salt water, requiring water through a semipermeable membrane while rejecting dissolved solids. This calls for significant pressure to get over osmotic pressure.

Secret components of an aquatic RO system:

- Pre-filtration: Gets rid of suspended solids and bits to protect the membrane, usually making use of rugged and finer cartridge filters (e.g., 20-micron, 5-micron). Correct pre-filtration extends membrane layer life.

- Yüksek Basınç Pompası: Supplies pressure (800-1,180 psi for seawater, 225-375 psi for brackish). to drive water via the membrane layer. Pump performance effects energy usage.

- RO Membrane: The core splitting up aspect. Modern spiral-wound membrane layers attain high denial prices (> 99% for multi-charged ions, 90-96% for single-charged) [10] Membrane number and size determine capability.

- Stress Vessel: Robust housing for the RO membrane layer components, created for high stress.

- Energy Healing Devices (ERDs): Critical for efficiency, recovering hydraulic energy from the salt water stream to pre-pressurize feed water, lowering pump lots [6] Usual types include pressure exchangers (PX) and turbochargers. Isobaric devices like PX and DWEER are extremely efficient.

Regular process flow: Salt water intake -> crude purification -> finer pre-filters -> high-pressure pump -> membrane layer vessel -> permeate (fresh water) & brine (discharge). Solutions with ERDs straight high-pressure salt water with the ERD to pre-pressurize incoming feed water.

Focus element, linked to recovery price (permeate % of feed), is a vital layout parameter impacting pressure and brine salinity. Breakthroughs concentrate on energy efficiency, smaller footprint, and automation.

How wo choose a System Sizing, Ability, and Combination based on Vessel Type?

Choosing a system depends on vessel qualities and water need:

- Vessel Size/Type: Larger vessels (superyachts, commercial ships) require higher ability systems with more space and power. Smaller sized vessels (coastal cruisers) require small, energy-efficient devices.

- Number of Individuals: Primary chauffeur of need. Daily usage varies; determine demands based on individuals, trip duration, and activities

- Meant Usage: Water quality needs differ (alcohol consumption, cleaning, technical). Consuming alcohol water may need post-treatment and possibly reduced recovery for much better salt denial.

- Trip Duration/Location: Longer trips require even more ability. High salinity or chilly water influences efficiency and power make use of , potentially needing a bigger system.

- Offered Space/Structure: Systems need area for parts (pump, membrane layers, filters, controls) and pipes. Dimensions and weight should fit the vessel. Setup needs space for consumption, discharge, and storage. Engine-driven systems require engine compartment room.

Capabilities vary from loads to countless liters per hour. Modular or dispersed systems fit numerous spaces. Vibration seclusion is important for components.

Power Needs, Energy Resources, and Performance

Marine RO systems are energy-intensive, specifically the high-pressure pump. Power source assimilation and effectiveness are critical.

Typical source of power:

- a/c Electric: For vessels with AC generators or large inverters. Common on larger watercrafts (> 40 ft) with generators.

- DC Electric: Incorporates with vessel DC circuits, including renewables (solar, wind). Preferred for mid-size cruisers. Can strain 12V/24V systems, potentially needing upgrades.

- Engine-Driven: High-pressure pump driven by the primary engine using belt/pulley. Highly effective, can decrease power intake dramatically (approximately 80% reported). The majority of reliable when the engine is running.

Energy intake differs. Modern RO is 2.5-4 kWh/m ³, but ERDs dramatically decrease this. High-efficiency ERDs can reduce specific energy intake (SEC) to 3 kWh/m THREE. Retrofitting can decrease SEC from 4.5 to 2.5 kWh/m FOUR. Power costs are significant (30-50% of overhead), making ERDs essential.

Specific ERDs like Danfoss iSave (incorporated PX/booster pump) are maximized for aquatic use, accomplishing approximately 94% performance. The iERD collection (3-in-1 PX, booster, motor) accomplishes as much as 92% recovery. ERDs are essential for decarbonizing SWRO.

Efficiency optimization approaches:

- Utilizing ERDs.

- Choosing reliable pumps/motors.

- Enhancing layout (membrane layer, pressure, recovery).

- Preserving components (clean filters/membranes).

- Taking into consideration environment (colder/saltier water boosts use).

Some systems are made for ultra-low power (e.g., Sea Recovery Ultra Whisper claims 75% decrease) . DC systems are typically extra effective with integrated ERS. ERDs include initial expense however use long-term savings. Crossbreed AC/DC options exist.

Water Top Quality, Post-Treatment, and Viability for Intended Usage

RO water is pure with low liquified salts/minerals. It’s devoid of bacteria/viruses yet might need additional therapy.

Desalinated water attributes: Low TDS, demineralized, somewhat acidic.

Needed post-treatment relies on use:

- UV Sterilization: Crucial for drinking water to kill germs after RO.

- Mineralization: Includes minerals (calcium, magnesium) for taste/health in drinking water.

- pH Modification: Increases pH if acidic (e.g., with calcium carbonate), assisting remineralization and decreasing rust.

- Triggered Carbon: Eliminates recurring odors/tastes.

Monitoring TDS with a conductivity meter ensures efficiency. Bacterial screening may be needed for drinking water.

Viability for usages:

- Drinking: Needs post-treatment (UV, mineralization, pH).

- Washing/Showering: Normally needs just UV sanitation. Reduced minerals lower soap residue.

- Technical Usage (Engine Cooling): Low mineral web content prevents scaling; typically no post-treatment required.

Salt water discharge is an environmental factor to consider. Brine is focused (twice seawater salinity) and can include therapy chemicals. Release can increase local salinity/temperature, lower oxygen, and create “dead zones” On vessels, salt water is discharged too far. Effect depends upon location/speed; open water permits quick dilution. Resource recuperation from brine is explored yet much less suitable to little aquatic systems.

Setup, Procedure, and Maintenance in the Marine Environment

Marine systems need details installment, procedure, and upkeep methods.

Setup: .

- Place: Accessible, secured from extremes, allows proper plumbing runs.

- Vibration Isolation: Mount components on moistening places.

- Pipes: Utilize corrosion-resistant materials (strengthened hose, high-pressure tubing). Secure connections. Intake far from contamination; release away from intake.

- Electrical: Appropriate wiring/fusing per requirements.

- Through-Hulls: Robust, corrosion-resistant fittings for intake/discharge.

Operation: .

- Directions: Follow maker startup/shutdown.

- Tracking: Examine stress, circulation rates (feed, penetrate, salt water), penetrate TDS.

- Feed Water: Stay clear of contaminated locations (harbors, blooms) to stop fouling.

- Çalışma süresi: Run long enough to satisfy requirements, minimize start/stop cycles.

Maintenance: .

- Pre-filter Substitute: Frequent task; change per timetable or when stress decreases.

- Membrane Cleaning: Chemical cleansing needed when fouling lowers production/quality. Frequency depends on feed water/usage.

- Membrane Substitute: Membranes have limited life (numerous years). Replace when cleansing falls short or top quality drops.

- Element Examination: Examine pump, electric motor, and so on, for leaks, rust, sound. Top-quality products (duplex/super-duplex) are used in vital parts.

- Preservation (Layup): Flush with fresh water, loaded with preservation option for prolonged non-use.

- Rust Avoidance: Evaluate and deal with corrosion promptly.

- Troubleshooting: Address reduced production (filters, membranes, pressure), low quality (membranes, leakages), pump issues. Use circulation diagram and guide.

Get A Quote Today!

Relate Products