Project Overiew

Bordered by turquoise seas, where sunlight and sandy beaches abound. Nonetheless, fresh water sources are as valuable as gold. The brackish water drawn out from deep underground wells as soon as positioned a considerable survival difficulty for the island’s residents. Today, a 20-foot container has actually quietly changed this fact– it is a ‘mobile water plant’ capable of creating 5 cubic metres of pure alcohol consumption water per hour. Just how did we accomplish this? Let’s have a look at this design diary.

Curaçao’s Alcohol consumption Water Situation

Behind the beauty of the Caribbean island country of Curaçao lies the harsh fact of serious freshwater scarcity. Depending on groundwater from wells, the salted taste and high salinity made the water undrinkable, motivating an immediate need for a cost-effective, effective, and ready-to-use service. Our objective was clear: to create a standard container efficient in ‘producing water.’

How did we design the containerizd brackish water plant?

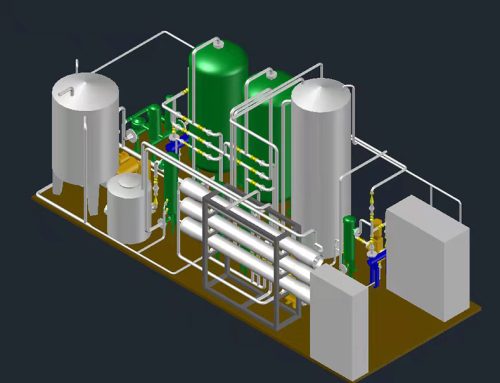

Opening up the container discloses a complete and effective briny water desalination production line:

1. Source control: Well water is injected right into the raw water container and pumped right into the pre-treatment system using the feed pump.

2. Purification:

- Multi-media filter storage tank: Intercepts big bits such as sand and corrosion.

- Activated carbon filter storage tank: Highly adsorbs residual chlorine, odours, and tiny natural molecules.

- Chemical defense system: Real-time application system (anti-bacterial to remove microbes, lowering agent to safeguard membrane aspects, and scale inhibitor to prevent scaling).

- 5μm security filter cartridge: The last line of protection, making sure that fragments larger than 5 microns do not get in the core devices.

3. Desalination:

- High-pressure pump: Boosts water pressure to the required thrust for reverse osmosis.

- BWRO reverse osmosis membrane layer assembly: The core of the task! Brackish water travels through a special membrane layer under high pressure, accomplishing ≥ 98% desalination performance, separating out high-purity freshwater, with a stable healing rate of ≥ 50%– for each 2 tonnes of brackish water processed, at least 1 tonne of safe and clean freshwater is generated.

4. Safe Shipment:

- Freshwater is kept in a container and supplied using a water pump.

- UV Steriliser: Suspends prospective bacteria and infections at the last.

- Pressure Storage Tank + Precision Filter: Stabilises water stress, carefully filters recurring particles, guaranteeing the faucet water is directly clear, crisp, and pleasant.

What corrosion-resistant treatments have been put on the equipment in a high-salt, high-humidity setting like Curaçao?

1. Use of corrosion-resistant materials

- Stainless-steel and duplex steel: Vital structural parts (such as high-pressure pumps and RO membrane housings) are constructed from 316L stainless steel or 2205 duplex stainless-steel, which create a passivation movie via chromium/nickel/molybdenum aspects to resist chloride ion penetration.

- Titanium alloy elements: Components touching seawater (such as pipe joints and shutoffs) make use of titanium alloy, whose natural oxide film can withstand salt water deterioration, with a life span of over twenty years.

- Aluminium alloy frameworks: Equipment real estates make use of 5-series/6-series aluminium alloy, balancing light-weight layout with salt spray resistance to lower general deterioration risk.

- Compound material choices:. Non-pressure pipes and storage tank cellular linings use glass-fibre enhanced plastic (GFRP) or carbon-fibre reinforced plastic (CFRP) to get rid of electrochemical corrosion, ideal for turned on carbon filter tanks, etc II. Surface protective covering system.

2. Multi-layer sturdy corrosion-resistant layer:.

- Primer: Epoxy zinc-rich primer (zinc web content ≥ 80%), which actively resists damaged areas with a cathodic security device.

- Intermediate coat: Thick-film epoxy micaceous iron oxide paint (density 200μm), which fills pores and obstructs water vapour infiltration.

Topcoat: Polyurethane or fluorocarbon topcoat, resistant to UV aging and with a hydrophobic surface to lower salt attachment.

Advanced Finishing Technology:. - Nano-modified Finish: Includes silica/alumina nanoparticles to enhance coating thickness and abrasion resistance.

- Self-healing Covering: Embeds deterioration preventions using microcapsule innovation, immediately releasing repair substances upon damage (e.g., for container covering joints).

3. Electrochemical protection technology

- Sacrificial anode system:. Set up zinc/aluminium-based sacrificial anode obstructs on the internal walls of freshwater tanks and raw water storage tanks to corrode preferentially and protect the steel substrate, with regular substitute (about every 2– 3 years).

- Satisfied present cathodic protection (ICCP): ICCP is utilized for large tank or underground pipes, with present controlled by a consistent prospective instrument to exactly reduce electrochemical corrosion.

4. Architectural design and environmental control

Water drainage design:. The equipment base is inclined at 5 ° for drain to avoid salt accumulation; welded joints utilize continuous complete welds + sealant filling up to get rid of hole deterioration.

Microenvironment Control: The container interior is furnished with a dehumidifier (humidity ≤ 50%) and a salt haze filtration fresh air system to decrease the focus of interior corrosion factors. Electrical control cupboards are full of nitrogen to isolate them from humid oxygen atmospheres.

Treatment results

✅ Desalination Rate ≥ 98%.

✅ Recuperation Price ≥ 50%.

✅ Water production rate: 5 m ³/ h (i.e., 5,000 litres per hour).

Why select a containerised containerized brackish BWRO system?

- Plug-and-play: The whole unit is pre-installed and tested; upon arrival at the website, just water and power connections are required, reducing the setup period by 70%.

- Corrosion-resistant and weatherproof: The container and procedure equipment go through special therapy, making them immune to high-salt and high-humidity environments on islands.

- Flexible and mobile: Need even more capability? Merely transport one more container and link it in parallel. Water lack in the region? The tools can be transferred at any moment to offer support.

- Cost-efficient: Eliminates framework costs compared to standard projects, with transportation and training expenses significantly lower than those of massive tools.

What modifications has it offered the local area?

- Minimized reliance on purchased freshwater, considerably reducing water costs;.

- High-standard UV + dual-stage purification makes sure water quality satisfies international alcohol consumption water standards;.

Bugün Bir Çözüm Bulun!