With global population growth and economic development, demand for freshwater resources continues to rise, while traditional freshwater sources face depletion risks. Although 71% of Earth’s surface is covered by water, only 0.26% of the planet’s total water volume constitutes freshwater truly accessible for human use. Desalination technology transforms seawater into potable freshwater, offering a new pathway to address freshwater scarcity.

By 2008, desalination had become the primary drinking water source for approximately 75 million people, with this figure continuing to grow rapidly. The expanding populations of coastal cities—where over 75% of residents in regions like Australia, the Middle East, and Southern California live near coastlines—make desalination technology particularly vital in these areas.

Global daily desalination output stands at approximately 35 million cubic meters, with 80% used for drinking water, addressing the water needs of over 100 million people—meaning one in fifty people worldwide relies on desalinated water for drinking. With over 13,000 desalination plants globally, this technology is increasingly recognized by many coastal nations as an alternative and supplemental source of freshwater.

What Seawater Desalination Plant Best Fits Your Needs?

When evaluating seawater-to-freshwater solutions, first clarify what “best fit” means: lowest operating costs? Lowest energy consumption? Smallest footprint or fastest installation? Different applications—residential, commercial, industrial, emergency, or mobile deployments—demand varying system capacities, product water quality, footprint, and maintenance capabilities. Therefore, determining the most suitable system for you requires a clear needs assessment: expected daily water production, permissible feed water TDS range, desired product water quality (potable, industrial, or process water), on-site power conditions, long-term operational budget, and environmental constraints (such as seawater discharge permits for brine). Only after synthesizing these factors can the most appropriate technological approach and equipment specifications be selected—rather than simply choosing “the best” option.

What Seawater Desalination Technologies Are Available?

Seawater desalination technologies are primarily divided into distillation (thermal) and membrane methods. Globally, over 20 desalination technologies exist, including reverse osmosis, low-pressure multi-effect distillation, multi-stage flash distillation, electrodialysis, pressurized vapor distillation, dew point evaporation, combined hydroelectricity and desalination, combined thermal and membrane processes, as well as technologies utilizing nuclear, solar, wind, and tidal energy. Reverse osmosis (RO) is currently the most widely adopted desalination technology. It employs a semi-permeable membrane that allows only the solvent (water) to pass through while blocking the solute (salts), thereby separating seawater from freshwater. This method offers advantages such as low capital investment and energy consumption, though it requires extensive seawater pretreatment. The greatest advantage of reverse osmosis is its energy efficiency, consuming only half the energy of electrodialysis and one-fortieth that of distillation. Consequently, since 1974, developed nations like the United States and Japan have progressively shifted their focus toward reverse osmosis.

Multi-Stage Flash (MSF) involves evaporating heated seawater sequentially through multiple flash chambers with progressively decreasing pressure, condensing the vapor to produce freshwater. Currently, MSF remains the most widely adopted desalination method globally, offering the highest production capacity, most mature technology, high operational safety, and flexibility. Primarily integrated with thermal power plants, it suits large-scale and ultra-large desalination facilities and is predominantly used in Gulf nations.

Multi-Stage Flash (MSF) involves evaporating heated seawater sequentially through multiple flash chambers with progressively decreasing pressure, condensing the vapor to produce freshwater. Currently, MSF remains the most widely adopted desalination method globally, offering the highest production capacity, most mature technology, high operational safety, and flexibility. Primarily integrated with thermal power plants, it suits large-scale and ultra-large desalination facilities and is predominantly used in Gulf nations.

Multi-Effect Distillation (MED) involves evaporating heated seawater through a series of cascading evaporators. The vapor from each preceding evaporator serves as the heat source for the next, condensing into freshwater. MED technology has seen rapid development due to its energy efficiency, with increasing plant scales and decreasing costs.

Types of Seawater Desalination Plants

The broad applicability of desalination plant has driven the development of diverse systems tailored to specialized needs. Consequently, the market offers numerous customized desalination units to meet specific operational requirements. Below are the various desalination systems produced by NEWater.

Industrial Desalination Systems

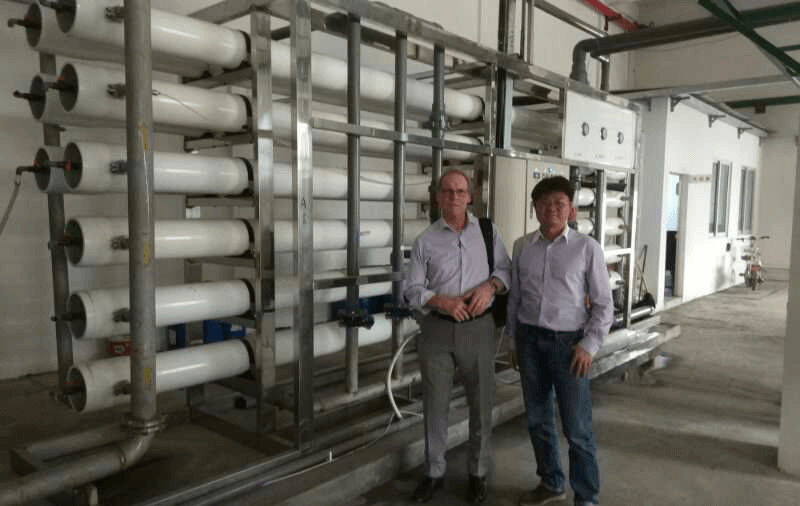

KYsearo provides a comprehensive range of desalination units specifically engineered for continuous seawater desalination in both onshore and offshore industrial settings. Industrial sectors demand substantial volumes of high-quality water, while dwindling natural freshwater resources compel numerous industries to seek alternative water sources.

Reverse osmosis technology is widely adopted in industrial desalination to produce high-standard water suitable for manufacturing, potable water, and equipment cleaning. To accommodate varying industrial scales, NEWater’s reverse osmosis desalination units offer standard capacities up to 900,000 gallons per day.

Commercial Desalination Systems

Global freshwater scarcity has adversely impacted most commercial entities. Consequently, seawater desalination has become a critical solution for enterprises in coastal and arid regions.

KYsearo’s commercial desalination facilities offer standard capacities ranging from 350 to 15,000 gallons per day. This provides a continuous, reliable freshwater supply for businesses of all sizes, including small-to-medium enterprises and large commercial organizations. For specialized requirements beyond standard specifications, our team of professional engineers provides custom-built solutions.

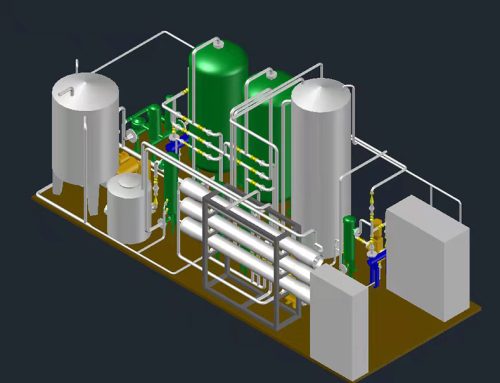

Skid mould and Containerized Desalination Plants

For skid mounld, Kysearo-manufactured desalination equipment can be mounted on steel frames or integrated into standard shipping containers. Containerized desalination systems typically feature desalination units integrated within 20-foot or 40-foot containers. Whether modular or containerized, these units are suitable for diverse indoor and outdoor installation environments.

These systems deliver exceptional desalination performance, typically reducing Total Dissolved Solids (TDS) from over 35,000 ppm to approximately 500 mg/L. All systems are assembled in our proprietary manufacturing facilities and undergo rigorous testing to ensure product quality and reliable performance.

;;

How are the difference for industrial, commercial, and residential desalination systems ?

Different applications impose distinct requirements on technical specifications and engineering implementation:

- Residential/Small Commercial: Daily treatment capacities typically range from tens to thousands of liters, emphasizing compact footprint, ease of operation, low noise, and minimal maintenance. Systems primarily feature modular RO units with integrated pretreatment and basic post-treatment, often offering plug-and-play functionality.

- Commercial Applications (Foodservice, Hotels, Office Buildings): Moderate demand requires continuous, stable supply meeting consistent drinking water standards and quality. Systems often feature medium-scale RO units with enhanced pretreatment, softening, and disinfection processes, supported by automated monitoring.

- Industrial Users (Pharmaceutical, Electronics, Chemical, Power Generation, etc.): Often demand higher water quality specifications (conductivity, dissolved organic matter, microbiological parameters) and require large volumes. Industrial-grade systems require redundant design, facilitate cleaning-in-place (CIP), offer highly controllable operating parameters, and frequently integrate with downstream treatment (deionization, mixed-bed, ultrapure water systems). Industrial applications also require consideration of specific process water parameters (e.g., silica, boron, conductivity).

Additionally, industrial installations typically invest more in durability, material selection (corrosion-resistant stainless steel, specialized coatings), and remote monitoring capabilities.

How is Seawater Desalination Plant Process?

- Intake and Screening: Seawater is drawn from the ocean and passed through screens and filters to remove large particles and floating debris.

- Pretratamiento: Removes suspended solids, algae, organic matter, and microorganisms. Common methods include sedimentation, coagulation, filtration (sand filtration, membrane filtration like ultrafiltration/microfiltration), flocculation, disinfection, or chemical dosing (scale inhibitors, anti-fouling agents). This protects downstream membranes or thermal equipment while preventing contamination and fouling.

- Main Desalination Process: Treats pretreated seawater through a specific desalination method to produce freshwater (detailed below).

- Post-Treatment (Conditioning): Freshwater typically requires pH adjustment, mineral replenishment (e.g., calcium, carbonate), and disinfection to ensure compliance with potable or industrial standards.

- Brine (Saltwater) Treatment and Disposal: Dilution, further treatment, or appropriate disposal methods (seawater discharge, injection, evaporation, zero liquid discharge systems, etc.) are applied to the high-salinity wastewater generated during desalination to minimize environmental impact.

Working Principles of Seawater Desalination Plants

Working Principles of Seawater Desalination Plants

- Reverse Osmosis (RO)

- Principle: High pressure forces seawater through a semi-permeable membrane, overcoming osmotic pressure to allow water molecules to pass while retaining salts and dissolved solids.

- Operating Conditions: Seawater osmotic pressure is approximately tens of bars (depending on salinity). Seawater RO typically operates at pressures around 50–80 bar (5–8 MPa), varying with salinity and recovery rate.

- Ventajas: Relatively low energy consumption, widely applied in large-scale water supply. Modern large-scale SWRO plants with energy recovery devices (ERD) typically consume about 3–6 kWh/m³ electricity (specific to design and feedwater quality).

- Desventajas: Sensitive to feedwater quality (requires effective pretreatment), prone to membrane fouling/scaling necessitating periodic chemical cleaning and membrane replacement; produces brine concentrate.

2. Multi-Stage Flash (MSF) and Multi-Effect Distillation (MED)

2. Multi-Stage Flash (MSF) and Multi-Effect Distillation (MED)

- Principle: Based on evaporation/condensation. MSF flashes heated seawater in a series of chambers at varying pressures, condensing vapor into freshwater; MED utilizes steam as a heat source through multi-effect evaporation, maximizing thermal efficiency.

- Energy: Primarily thermal energy (steam, waste heat, solar, etc.), often used in cogeneration or where cheap heat sources are available.

- Advantages/Disadvantages: Well-suited for high-salinity feedwater and relatively tolerant of feedwater variations, but high thermal energy consumption, large equipment footprint, and complex operation/maintenance. MED typically achieves higher thermal efficiency than MSF.

3. Electrodialysis (ED / EDR)

- Principle: Under an electric field, alternating cation/anion exchange membranes drive ions from the permeate stream toward the concentrate stream. Suitable for lower salinity ranges (brine/brackish water).

- Ventajas: High efficiency for low to medium salinity water; energy consumption correlates with salinity. Not economical for high-salinity seawater.

Membrane Distillation, Forward Osmosis (FO), Freezing, Capacitive Deionization (CDI), etc.

Primarily used in laboratory/niche or specialized applications. Possess potential advantages (e.g., low-temperature operation, utilization of waste heat or solar energy), but vary in commercial scale and maturity.

Key Performance Indicators

- Recovery Rate: Freshwater output / Feedwater input. Typical seawater RO recovery ranges from 30–50% (depending on design and environmental requirements).

- Specific Energy Consumption: Modern SWRO plants consume approximately 3–6 kWh/m³ of electricity (including high-efficiency energy recovery systems); thermal methods measure energy in thermal units, while MED/MSF have distinct thermal requirements.

- Water Quality: Product water conductivity, total dissolved solids (TDS), microbial parameters, etc., must meet standards.

Common Issues and Control

- Fouling/Biofouling: Mitigated through periodic cleaning, biocide dosing, or pre-membrane ultrafiltration.

- Scaling: Occurs when salts deposit on membrane surfaces; commonly addressed with scale inhibitors, pH control, and backwashing.

- Corrosion and Material Selection: Saltwater environments are highly corrosive, requiring suitable materials and cathodic protection.

- Environmental Impact of Brine Discharge: High salinity, heavy metals, and chemical residues may affect marine ecosystems. Proper dilution, strategic discharge locations, or further treatment/resource recovery (e.g., bromine or salt extraction) are necessary.

Selection Considerations (RO vs Thermal Methods, etc.)

- Energy Availability and Cost: MED/MSF may be suitable if inexpensive heat sources or waste heat are available; RO is preferred where electricity is cheap and minimal footprint is required.

- Scale and Application: SWRO is commonly used for large-scale municipal water supply; systems compatible with renewable energy may be considered for small-scale or remote applications.

- Feedwater Quality: Water with high turbidity or heavy organic contamination requires more intensive pretreatment, influencing technology selection.

- Environmental and regulatory considerations: Discharge limits, water abstraction permits, and marine ecosystem protection requirements influence design.

Energy-saving and optimization measures

- Pressure recovery devices (PRD, ERD) significantly reduce energy consumption in RO systems.

- Recover resources (salt, bromine, etc.) from brine or adopt zero liquid discharge (ZLD) technology.

- Utilize low-velocity membranes, advanced pretreatment, or online monitoring to optimize operation and reduce cleaning frequency.

- Couple with renewable energy sources (wind, solar, solar thermal) to reduce fossil fuel consumption.

If required, Kysearo can:

- Provide detailed process flow diagrams, key equipment lists, and design parameter recommendations for specific processes (e.g., SWRO or MED);

- Provide rough estimates for energy consumption, recovery rates, or operating costs (requires input TDS, design capacity, available energy sources, etc.).

What Are The Key Components Of a Seawater Desalination Plant?

Regardless of the desalination process, a high-performance desalination plant comprises several core components. Understanding these elements aids in equipment selection and maintenance:

- Pretreatment unit: Includes coarse screens, sand filters, coagulation/flocculation, media filtration, activated carbon filtration, and chemical dosing equipment. This stage removes large particles, organic matter, and reduces biological load to protect downstream membranes or thermal equipment from fouling and scaling.

- High-pressure pump (RO systems): Provides essential operating pressure for the membrane system, serving as a critical component for RO system performance and efficiency; its selection directly impacts energy consumption and reliability.

- Semi-permeable membrane assembly (RO membrane): Determines desalination rate and product water quality; membrane material, pore size, and arrangement dictate production efficiency and durability.

- Energy recovery device (ERD): Includes pressure recovery

How to Evaluate the Energy Consumption and Efficiency of Seawater Desalination Plants?

Energy consumption serves as a core metric for assessing desalination economics, typically expressed as energy consumption per unit of produced water (kWh/m³) or total energy cost (USD/ton). Key considerations during evaluation include:

- Higher feedwater TDS (Total Dissolved Solids): requires greater pressure and energy, with RO system energy consumption positively correlated to feedwater salinity;

- System capacity and economies of scale: Large centralized plants typically achieve better performance in energy consumption and unit maintenance costs;

- Presence and efficiency of energy recovery systems: Modern high-efficiency ERDs can reduce RO system electricity consumption by approximately 20%–40%;

- Pretreatment quality directly impacts membrane flux retention time and cleaning frequency, thereby influencing long-term energy consumption and maintenance energy requirements;

- Thermal process energy consumption is typically expressed in thermal units (kWh thermal equivalent or GJ), which can be converted to electrical energy equivalents based on heat source costs (steam or fuel);

- Overall system efficiency must also account for operational time utilization, additional energy consumption from standby and redundancy, and downtime losses due to maintenance.

For example: Typical electricity consumption in modern seawater RO systems ranges from 3–7 kWh/m³; in thermal processes, typical MED electricity consumption is approximately 6.5–11 kWh/m³ (thermal energy converted to electrical equivalent), while MSF can reach as high as 13.5–25.5 kWh/m³. Energy pricing, availability, and long-term volatility must be incorporated into economic models during evaluation.

What Are The Advantages of Seawater Desalination Plants

Low Energy Consumption: Energy efficiency is a crucial attribute of a good desalination system. New desalination plants incorporate energy recovery technologies, which play a significant role in reducing energy consumption. The greatest advantage of reverse osmosis is its energy efficiency, consuming only half the energy of electrodialysis and one-fortieth that of distillation.

High Desalination Rate: Fundamentally, a desalination system’s effectiveness depends on the contaminants it can remove. Reverse osmosis excels at removing dissolved salts from seawater, achieving a maximum desalination rate of 99.7%. Typical seawater contains an average total dissolved solids (TDS) level of approximately 35,000 ppm. An excellent desalination system can reduce TDS levels below 1,000 ppm, the minimum requirement for producing potable freshwater.

Sufficient Capacity: An ideal desalination system possesses capacity perfectly suited to its intended application. Industrial desalination systems utilizing reverse osmosis technology typically range in standard capacity from 8,000 gallons per day (GPD) to 660,000 GPD. Superior Quality: High-quality equipment ensures extended service life and reduces the need for frequent maintenance or replacement. Premium desalination systems are constructed from corrosion-resistant stainless steel, capable of withstanding prolonged exposure to high-salinity seawater.

Cost-Effectiveness: The cost of a desalination system often reflects the combined impact of various production, market, and operational variables. A well-designed system delivers substantial return on investment within a relatively short timeframe. RO desalination systems, primarily used for seawater desalination, typically consume electricity at a rate of approximately RMB 2.25 per metric ton of water produced.

In which specific sectors is seawater desalination technology applied?

Domestic Drinking Water: With accelerated urbanization and population growth, many coastal and inland cities face freshwater shortages. Desalination has become a vital solution for addressing drinking water scarcity in these regions. Countries like the UAE, Kuwait, and nations across North Africa, Europe, North America, and Southeast Asia rely on desalination to supply drinking water to their populations. Countries like Saudi Arabia, the United Arab Emirates, and the Maldives rely almost entirely on desalinated water.

Industrial Water: Industrial production demands high-quality water, and desalination provides high-purity freshwater suitable for cooling, washing, chemical manufacturing, and other industrial applications. Its use is increasingly widespread in sectors like energy, chemicals, and electronics.

Agricultural Irrigation: With agricultural modernization, demand for irrigation water continues to rise. Desalination offers an alternative water source, particularly in arid and semi-arid regions. However, its application in agricultural irrigation is limited to low-salt crops and incurs significant costs.

Additionally, desalination technology finds extensive applications in emergency water supply (for disasters or military purposes), tourist facilities, and marine aquaculture, establishing itself as a diversified, comprehensive water resource solution. On maritime platforms like ships and naval vessels, reverse osmosis desalination equipment plays a vital role in providing stable, reliable freshwater supplies for crews.

How to Estimate the Total Cost of a Desalination Project?

Total Cost of Ownership (TCO) encompasses both Capital Expenditure (CAPEX) and Operating Expenditure (OPEX). A comprehensive assessment is necessary to determine the true unit water production cost (RMB/ton or RMB/m³):

- CAPEX: Equipment procurement, civil works and foundations, utility connections (power/heat sources), piping networks and discharge facilities, installation and commissioning, engineering design and permitting fees. Large custom-built plants have higher CAPEX ratios but may offer better unit capacity amortization advantages.

- OPEX: Electricity or fuel costs, chemicals (coagulants, backwash chemicals, membrane cleaning agents), membrane and critical spare part replacements, personnel wages, maintenance, waste brine treatment fees, depreciation, and insurance. Long-term operating expenses significantly impact TCO.

- Other expenses: Land lease, environmental compliance fees (discharge permits, monitoring), taxes, and financing interest.

- Economic evaluations should include discounted cash flow (NPV), payback period, and sensitivity analysis (to energy prices, membrane lifespan, and water price fluctuations).

Example Estimate (Simplified): Assuming an RO plant with a daily capacity of 10,000 m³, initial equipment and construction cost X, annual energy consumption Y kWh, electricity price Z CNY/kWh, and annual membrane replacement frequency/cost plus labor/maintenance expenses totaling C, the unit water production cost approximates (annual depreciation + annual OPEX) / annual water production volume. Actual projects require detailed data input into the model for precise results.

What are the environmental impacts of seawater desalination and mitigation strategies?

While seawater desalination alleviates water shortages, improper management can cause environmental issues. Common impacts and corresponding mitigation measures include:

- Brine discharge: High salinity, temperature, or chemical residues impact marine ecosystems. Mitigation strategies: Design discharge outlets for more uniform mixing, use diffusers, select appropriate discharge depth and location, further concentrate brine for resource recovery (e.g., salt reclamation), or employ land-based evaporation and mineral precipitation to reduce toxic emissions.

- Energy consumption and carbon emissions: Significant electricity or fuel use increases greenhouse gas emissions. Mitigation strategies: Employ energy recovery technologies, integrate renewable energy sources (e.g., solar PV, wind power), or utilize industrial waste heat; enhance energy-efficient design and implement energy management systems.

- Chemical usage: Substances used in pretreatment and membrane cleaning may cause secondary environmental pollution. Mitigation strategies: Optimize chemical dosing, select environmentally friendly products, and establish chemical waste liquid treatment and neutralization systems.

- Ecological and fishery impacts: Noise, light disturbance, and emissions during construction and operation can affect coastal organisms. Mitigation strategies: Conduct environmental impact assessments (EIA) during site selection, implement mitigation measures during operation, and conduct long-term ecological monitoring.

Through integrated design and management, environmental impacts can be minimized while achieving water supply objectives, meeting regulatory requirements, and supporting sustainable development goals.

How to Select Suppliers and Ensure Equipment Quality?

Selecting high-quality suppliers is crucial for ensuring long-term operational stability. Consider the following key points:

- Qualifications and Certifications: Verify ISO quality management system certification, industry patents, third-party test reports, and compliance certificates;

- Project Experience & Case Studies: Prioritize suppliers with implementation and operational experience in similar-scale projects; review successful case studies and user feedback;

- Design & Manufacturing Capabilities: Verify provision of complete engineering design, customization capabilities, and whether critical components (e.g., membranes, pumps, ERD) are from reputable brands or proprietary R&D;

- Warranty & After-Sales Support: Warranty duration, spare parts supply capability, remote monitoring and emergency response time, training and technical support commitments;

- Cost-effectiveness and long-term expenses: Evaluate not only purchase price but also long-term energy consumption, maintenance, and replacement costs;

- Transparency: Can the supplier provide detailed technical specifications, operational curves, actual energy consumption data, and third-party performance verification?

When signing the contract, clearly define acceptance criteria, performance guarantee metrics (e.g., water production rate, salt rejection rate, maximum energy consumption), breach clauses, and after-sales service details.

What are best practices for daily operation, maintenance, and extending equipment lifespan?

Effective operation and maintenance strategies not only ensure water quality but also significantly reduce long-term operational costs. Key practices include:

- Strictly enforce pretreatment maintenance: Regularly inspect and clean sand filters, carbon filters, and coagulation units to ensure stable feedwater quality;

- Conduct regular online membrane monitoring and periodic chemical cleaning (CIP): Set cleaning thresholds based on transmembrane pressure difference (ΔP), flux decline, and permeability; select appropriate cleaning agents and maintain cleaning logs;

- Perform preventive maintenance on high-pressure pumps and drive systems: Adhere to manufacturer recommendations for shaft seal maintenance, lubricant replacement, and bearing inspections; avoid water hammer and frequent start-stop cycles;

- Energy recovery device maintenance: Maintain cleanliness and sealing integrity of ERD components to sustain recovery efficiency;

- Automation and remote monitoring: Utilize SCADA systems for real-time collection of critical parameters (pressure, flow rate, conductivity, temperature), configure alarms and remote diagnostics to reduce manual inspection workload;

- Maintenance records and spare parts inventory management: Establish detailed operational logs and spare parts inventories to ensure timely availability of critical components (membrane elements, valves, motors);

- Personnel training: Ensure operators master standard operating procedures, safety protocols, and basic troubleshooting skills;

- Regular Third-Party Performance Assessments: Engage independent agencies for performance testing and energy audits to verify equipment compliance with contractual specifications.

These measures extend membrane lifespan, reduce unplanned downtime risks, and optimize energy efficiency.

Frequently Asked Questions About Seawater Desalination Plants

Below are common user inquiries with core answers to help quickly identify project challenges:

Q: How often should RO membranes be replaced?

A: Membrane lifespan depends on feedwater quality and maintenance levels, typically lasting 3–5 years. Strict pretreatment and regular cleaning can extend this beyond 5 years.

Q: How is the unit water cost for desalination calculated?

A: Total costs including annual depreciation, energy expenses, chemicals, labor, maintenance, brine treatment, and depreciation must be allocated. Divide this sum by annual water production to derive the unit cost.

Q: How is brine treated?

A: Common methods include dilution and seaward discharge (requiring permits and environmental monitoring), further concentration with salt recovery, or blending with other wastewater streams. Strict compliance and environmental assessments are prerequisites.

Q: How is economic viability ensured in regions with volatile energy prices?

A: Design flexible energy portfolios (grid connection + energy storage + renewables) and prioritize energy recovery technologies to reduce price sensitivity.

Q: What rapid solutions exist for emergency or remote deployment?

A: Containerized or modular RO units with mobile power sources (generators or solar systems) and low-maintenance configurations are common strategies.

Case Study: Application Scenario Comparison and Selection Approach

To illustrate how different technologies align with practical applications, we present three typical scenarios with recommended approaches:

- Coastal small towns (daily demand: 1,000–5,000 m³): Prioritize modern RO plants with high-efficiency ERD and modular design; if local regulations permit, employ seawater discharge diffusers for brine treatment.

- Industrial park centralized water supply (daily demand: 10,000–50,000 m³, with waste heat): MED or MSF offer cost advantages for large-scale operations if stable, low-cost steam or industrial waste heat is available. For low electricity costs and extremely high water quality requirements, the RO + mixed-bed combination provides greater flexibility.

- Offshore platforms or mobile bases (daily demand: tens to hundreds of m³): Containerized RO or steam compression units are more suitable, considering equipment seismic resistance, corrosion protection, and ease of maintenance; paired with backup power generation and remote monitoring.

Each case should undergo technical-economic analysis and environmental impact assessment during the feasibility study phase.

What are the trends and future outlook for seawater desalination technology?

Future developments in seawater desalination technology will primarily focus on the following areas:

- Energy efficiency improvements: More efficient energy recovery systems, lower-pressure high-flux membranes, and low-energy pretreatment technologies will continue to reduce energy consumption per unit of water produced;

- Renewable Energy Integration: Solar-powered RO systems, wind-powered auxiliary systems, and energy storage solutions are reducing carbon footprints while enhancing self-sufficiency in remote areas;

- Intelligent Operations & Maintenance: AI- and big data-driven predictive maintenance, online quality optimization, and automated adjustments will reduce labor costs and extend equipment lifespan;

- Modular & Standardized Manufacturing: Higher levels of factory pre-assembly and modular design accelerate delivery cycles and minimize on-site construction risks;

- Brine Resource Recovery: Maturing technologies extract minerals from brine, produce commercial salt, or recover valuable elements like magnesium and potassium, reducing environmental burdens while creating new revenue streams;

- Membrane Materials and Anti-Fouling Technologies: Novel membranes, hydrophobic/hydrophilic surface modifications, and biofouling-resistant coatings enhance membrane longevity and stability.

What are the practical recommendations for decision-makers and engineers?

When advancing desalination projects, the following practical steps are recommended:

- Conduct comprehensive feasibility studies: Including water quality testing, water demand analysis, energy resource assessment, environmental constraints, and economic modeling.

- Prioritize small-scale pilot projects: Obtain measured energy consumption, membrane flux decline curves, and brine characteristics through short-term trials to inform large-scale design.

- Adopt phased expansion strategies: Start with modular units and incrementally increase capacity based on demand growth to mitigate initial investment risks.

- Sign performance contracts: Establish key performance indicators (KPIs) with suppliers and incorporate warranty and maintenance services into contract terms.

- Strengthen training and knowledge transfer: Ensure local personnel can independently handle routine maintenance and common malfunctions, reducing reliance on external support.

- Develop long-term environmental monitoring plans: Regularly monitor coastal ecosystems, discharge outlet salinity, and temperature to ensure compliance and adjust discharge strategies promptly.

Conclusión

To initiate a seawater desalination project, follow this concise roadmap: First, conduct comprehensive water quality testing and needs assessment; second, perform economic and environmental feasibility studies while developing alternative technical solutions; third, select an experienced supplier for pilot testing and sign a clear performance contract; fourth, finalize discharge permits and environmental monitoring plans before commissioning; Fifth, deploy a comprehensive operations and maintenance system with staff training. Through a phased, data-driven decision-making process, water supply objectives can be effectively achieved while controlling long-term costs, all within a framework of compliance and environmental protection.

Should you require our assistance with preliminary feasibility assessments, technology comparisons, or supplier shortlisting, please provide the following information: estimated daily water consumption, seawater TDS and primary constituents in your coastal area, power and heat source availability, budget range, and project timeline. Based on these inputs, I can customize an initial proposal and evaluation framework to help you achieve the optimal balance between technical and economic considerations.

Get A Free Quote Today!