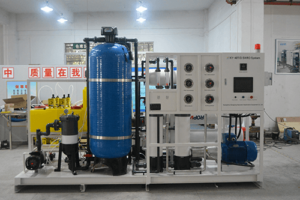

Brackish Water Reverse Osmosis Desalination System BWRO Plant

KYsearo’s brackish water desalination plant utilises reverse osmosis (RO) technology to treat high-salinity water like borehole water, river water etc. water sources, it’s capable of removing harmful substances efficiently, such as inorganic salts (e.g., chlorides, sulphates), heavy metals, organic matters, bacteria, viruses, partical, PFAS and so on. The fresh water treated by RO can be applied to many industries and daily purposes.

KYsearo, with a professional engineer team, provides comprehensive water solutions based on your water quality—including for water-scarce regions, islands, ships, and industrial applications to address shortages of drinking water and industrial water. We offer the following:

- Customized Pretreatment Systems

- Reverse Osmosis (RO) Systems

- Post – Treatment Solutions(PH/Sterilization)

- Monitoring and Control Systems(PLC)

- Maintenance and Service Support

Your Premier Brackish Water Reverse Osmosis Desalination System manufacturer

Untuk memastikan klien kami menerima kualitas terbaik dalam sistem desalinasi air payau, KYsearo Brackish Water Series desalination plant uses only the best parts and components, we maintain great professional working with many top vendors in seawater treatment industry, in case the client have specific requirement of brands or materials. Our sistem osmosis balik air payau are ideal in municipal,commercial and industrial settings.

All of our equipment are engineered and mad by our own production team, our professional knowledgeable engineers and staff are always ready to help and provide information to answer client’s questions. And you could completely trained the functionalities as well as the maintenance necessary for the different parts, contact usand allow us to figure out any desalinasi air payau masalah yang mungkin Anda alami.

Dapatkan Solusi Sekarang

Capacity and mebrane sizes of BWRO desalination system

| Model No. | Permeate Flow Rate | Membranes | |

|---|---|---|---|

| Liter/Hour | Size | Quantity | |

| KY-RO-1000L | 1000 | 4040 | 5 |

| KY-RO-2000L | 2000 | 8040 | 3 |

| KY-RO-3000L | 3000 | 8040 | 6 |

| KY-RO-4000L | 4000 | 8040 | 8 |

| KY-RO-5000L | 5000 | 8040 | 10 |

| KY-RO-6000L | 6000 | 8040 | 15 |

| KY-RO-7000L | 7000 | 8040 | 18 |

| KY-RO-8000L | 8000 | 8040 | 30 |

| KY-RO-9000L | 9000 | 8040 | 36 |

| KY-RO-10000L | 10000 | 8040 | 144 |

| KY-RO-20000L | 20000 | 8040 | 216 |

| KY-RO-30000L | 30000 | 8040 | 648 |

What are the main components for brackish reverse osmosis system?

- Sistem Pra-perawatan:

Self-cleaning filter: Removes large particles (such as sand, gravel, and suspended solids).

Multi-media/activated carbon filter: Adsorbs organic matter and residual chlorine, reduces turbidity (SDI ≤ 3). - High-Pressure Pump: Provides the required pressure for reverse osmosis (1.5–3.5 MPa). Common brands include Southern Pump (CNP) and Grundfos.

- Reverse Osmosis Membrane: The core desalination component. Brands include Dow (DOW), Toray, and Hydranautics, with a desalination rate ≥98.5%.

- Membrane Housing: FRP (fibre-reinforced plastic) material, corrosion-resistant and high-pressure-resistant, protects membrane elements.

- Control System:

PLC Automatic Control: Monitors pressure, flow rate, and conductivity, with low-pressure automatic shutdown protection (alarm at <0.05 MPa).

Cleaning System: Supports physical/chemical backwashing to extend membrane lifespan.

Single Pass vs Double Pass RO systems

High pressure (1.5–3.5 MPa) is applied to force water molecules to reverse osmosis through a semi-permeable membrane, retaining over 99% of salts, bacteria, and organic matter.

- Single-pass RO: Single-stage desalination, suitable for brackish water with TDS ≤ 6000 ppm, producing water with TDS ≤ 500 mg/L.

- Two-pass RO: Two stages of membrane depth desalination in series, producing water with TDS ≤ 20 mg/L (pure water standard), suitable for high-salinity or ultra-pure water applications.

How is the processes of brackish water reverse osmosis systems?

Pre-treatment: Quartz sand filtration (removes silt and sand), activated carbon adsorption (removes residual chlorine/organic matter), precision filtration (5μm particle retention).

RO membrane modules: Membranes from brands such as Dow (DOW) and Toray, with a desalination rate of ≥98.5%.

Post-treatment: UV sterilisation and microporous membrane filtration ensure water quality safety.

Operational safeguards: Control recovery rate (to prevent scaling), regularly clean membrane modules (to prevent contamination), and monitor SDI index (<5).

What are the advantages of desalination of brackish water?

- High Efficiency and Energy Saving: Power consumption per ton of water as low as 3-4 kW·h (single-stage RO), achieving over 30% energy savings compared to electrodialysis.

- Intelligent Operation: Fully automatic operation with remote monitoring support and automatic fault alarms.

- Long Service Life and Low Maintenance: Corrosion-resistant stainless steel/FRP materials ensure a service life of 15-20 years for the equipment; membrane elements last 3-5 years (chemically regenerable).

- Flexible Adaptability: Power supply compatible with 220V-440V/50-60Hz, suitable for ships and remote areas.

- Environmental Protection and Safety: No chemical additives; concentrated brine can be recycled for resource utilisation (e.g., salt evaporation for potassium and magnesium extraction).

Brackish VS. Seawater Water Desalination

Brackish water desalination:

- Salinity: TDS (Total Dissolved Solids) ranges from 500–10,000 mg/L, commonly found in inland groundwater, saline lakes, or coastal groundwater affected by seawater intrusion.

- Composition Characteristics: Primarily composed of chlorides and sulphates, may contain toxic substances such as high fluoride or arsenic, but ion concentrations are lower than in seawater.

Seawater water desalination:

- Salinity: TDS as high as 35,000 mg/L (approximately 3.5% salinity), primarily composed of Na⁺, Cl⁻, and other ions.

- Contaminants: Contains special ions such as boron and iodine (boron removal efficiency requires additional optimisation), as well as biological active substances like algae and microorganisms.

What are the applications of brackish water desalination plant?

1. Drinking Water Supply

- Highly saline-alkali regions: Addressing drinking water safety issues caused by excessive salt content in groundwater (e.g., chloride > 250 mg/L)

- Islands: Providing stable drinking water sources for islands and mountainous areas without grid coverage through containerised or skid-mounted equipment, such as the electrodialysis desalination plant in Changdao County, Shandong Province]

- High fluoride/arsenic regions: Simultaneously remove toxic substances such as fluoride and arsenic (removal rate >90%) to improve water quality in areas prone to endemic diseases.

2. Industrial Water Treatment

- Power and Boiler Systems: Provide ultra-low TDS (≤20 mg/L) boiler feedwater to prevent scaling and corrosion, used in thermal power plants and nuclear power stations

- Electronics and semiconductor manufacturing: Produce high-purity ultra-pure water (resistivity ≥ 18 MΩ·cm) to meet the precise rinsing requirements in chip and LCD screen production.

- Pharmaceuticals and food and beverage: Remove microorganisms and ionic impurities to ensure that injectable water and sterile pure water comply with GMP standards; used for beer filtration, juice deacidification, etc. Chemical industry circulating cooling water: Treating high-hardness brackish water, reducing calcium and magnesium ion concentrations, and extending equipment lifespan.

3. Shipping and special scenarios

- Ocean-going vessels and drilling platforms: Land-based or solar desalination units with integrated corrosion-resistant designs to address freshwater supply issues in remote maritime areas, with daily water production capacity up to 50 tonnes.

- Military and emergency disaster relief: Mobile equipment supports rapid deployment, providing emergency water sources for field troops and disaster relief sites.

4. Agriculture and ecological restoration

- Saline-alkali land irrigation: Nanofiltration (NF) technology for low-pressure desalination (operating pressure 0.75 MPa), converting slightly saline water (TDS 3000–5000 ppm) into irrigation water, improving soil quality.

5. Public and Municipal Systems

- Community and School Water Supply: Covers centralised water supply networks for residential properties, hotels, schools, etc.

- Wastewater Reuse and Environmental Protection: Treats electroplating wastewater to recover nickel and other heavy metals, or purifies industrial wastewater to meet discharge standards, achieving resource recycling.

Get A Quote Today!

Produk Terkait