Project Overview

Bohol Island, a prominent tourist destination in the Philippines, encounters freshwater lacks during the completely dry period. Local groundwater is impacted by seawater intrusion, with TDS values as high as 30,000– 35,000 mg/L, while neighborhood alcohol consumption water need to adhere to the Philippine National Drinking Water Requirement (PNSDW: TDS ≤ 800 mg/L). This job aims to develop a trustworthy sistem desalinasi air laut to attend to the everyday water needs of a 200-person neighborhood.

Technical Parameters for seawater reverse osmosis system

- Water Manufacturing Capability 40 m3 / day (scalable to 50 m3 / day)

- Raw Water TDS 35,000 ± 5,000 mg/L.

- Generated Water TDS ≤ 800 mg/L

- Recovery Rate 35%– 40%.

- System Energy Consumption ≤ 4.0 kWh/m FOUR

- Operating Temperature Variety 28– 40 ° C( Tropical climate-adapted).

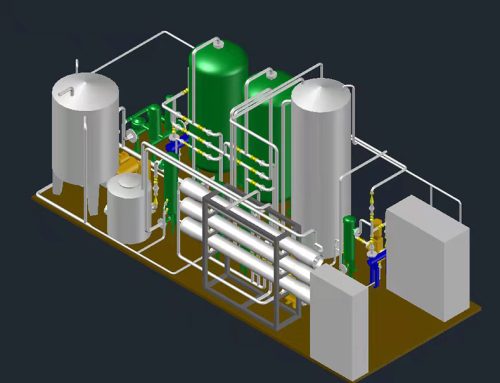

SWRO System Make-up and Cutting-edge Design

1. Pre-treatment Component.

- Multi-media filter: removes suspended solids (SS ≤ 50 μm).

- Automatic backwashing system: addresses high turbidity salt water during the rainy period (turbidity optimal 40 NTU).

- Range prevention application system: Avoids CaSO four crystallisation (controls LSI < 1.8).

2. Main Treatment Unit.

- Anti-fouling SWRO membrane component: DOW ro membrane (solitary membrane desalination rate 99.6%).

- One-stage pressure increasing arrangement:.

- Stage 1 high-pressure pump (3.5 kW): Increases pressure to 55– 60 bar.

3. Smart control system.

- PLC + HM human-machine interface: Real-time tracking of ORP/TOC/pressure.

- Cloud-based remote management: Sustains fault medical diagnosis (covered by Baohe Island 4G network).

4. Special setting adjustment.

- Container-style real estate: IP55 protection rating, immune to salt fog corrosion.

- Solar back-up system: 20 kW off-grid power supply (to resolve regular power outages).

Trick Obstacles and Solutions

| Challenge | Countermeasures | Effect |

|---|---|---|

| High-temperature seawater (33–35°C) | Dynamic membrane flux compensation algorithm | Stable water production ±5% |

| Frequent typhoons | Foundation securing + wind-resistant ballast style | Endures 10-level winds |

| Biofouling Shock | chlorine dioxide sanitation (0.5 ppm recurring) | CIP cleaning cycle extended to 90 days |

| Operational manpower shortage | Automatic chemical cleaning device (CIP) | Only requires monthly inspection once |

Water High Quality Confirmation (Third-Party Screening)

| Item | Raw Water (mg/L) | Produced Water (mg/L) | Typical Limitation |

|---|---|---|---|

| TDS | 34,852 | 382 | ≤800 |

| Chlorides | 19,450 | 196 | ≤600 |

| Boron | 4.8 | 0.45 | ≤2.4 |

| Total Colony Count | 920 CFU/mL | Not detected | ≤100 |

6. Economic Conveniences.

- Water manufacturing expense: 0.85 USD/m THREE (including procedure and maintenance).

- Yearly water cost savings: 14,600 m ³ (equal to decreasing 5,000 tonnes of shipped freshwater).

- Repayment duration: 3.2 years (contrasted to trucked water cost of 12 pesos/L).

7. Job Highlights.

✅ Bottleneck-free layout: 20% capability redundancy booked to fulfill peak need throughout the traveler period.

✅ Zero wastewater discharge: Focused salt water utilized for salt production at the community salt area (TDS ≈ 60,000 mg/L).

✅ Community empowerment: Training of 3 regional drivers (including 1 lady).

Note: The system has obtained ETWPS accreditation from the Philippine Division of Setting and Natural Resources (DENR) and abide by the DAO 2016-08 water discharge requirements.

8. Continuous Renovation Instructions.

1. Test brand-new graphene membrane layers (laboratory-stage change improvement of 47%).

2. Integrate a rain harvesting system (yearly boost in supply of water of 3,000 m FOUR).

3. Establish a mobile application for water bill settlements (covering 80% of smart device individuals).

This study efficiently demonstrates that modular reverse osmosis technology can achieve trusted water supply with low operational dependency with intelligent style in exotic island scenarios, supplying a replicable freshwater remedy for coastal communities in Southeast Asia.

If a PowerPoint variation of the technical proposal or design layout is needed, CAD/DWG layout in-depth style documents can be supplied.

Dapatkan Solusi Hari Ini!