1. Project Background

In the Philippines, freshwater shortage is a considerable concern, especially in certain coastal locations where citizens deal with difficulties in accessing secure and potable drinking water. To resolve this difficulty, our client introduced a 2,000 litres per hour solar-powered sea water desalination machine offered by KYSEARO. The SWRO system intends to convert high-salinity seawater right into safe and clean freshwater to satisfy the daily water needs of neighborhood homeowners.

2. Technical Parameters Of Solar Seawater Desalination Machine

This solar-powered salt water desalination system boasts superb efficiency, with the following technical parameters:

- Inlet water temperature level variety: 1– 40 ° C, pH value: 3– 11, total liquified solids (TDS) in inlet water should be less than 35,000 mg/L.

- The maximum TDS of the created water is 700 mg/L, conference alcohol consumption water criteria. The water flow price is 2 m THREE/ h, and the inlet water circulation price is 6 m ³/ h.

- The system recuperation price gets to 35%, with a desalination price of ≥ 98%, and the operating pressure is about 4– 6 MPa.

- The devices operates on a 380V, 3-phase, 60Hz voltage, with an approximate power demand of 23 kW · h each.

- The system is geared up with a 40 kW solar power supply system, consisting of 1 off-grid inverter (360 V-380 V/40 kW), 72 monocrystalline silicon photovoltaic panels (550 W/42 V), and 180 batteries (2 V/500 Ah), efficiently making use of the bountiful regional solar power resources and minimizing reliance on typical electrical energy.

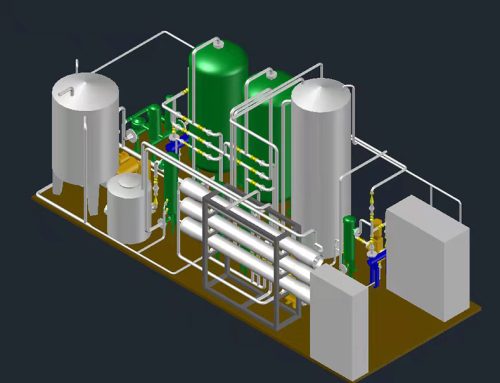

3. Solar Seawater Desalination Machine Structure and Functions

- Pre-treatment System : Include a sand filter and a protection filter (5μm and 1μm filter cartridges). The sand filter is constructed from fiberglass-reinforced plastic and full of polished quartz sand, capable of removing impurities such as rust, silt, algae, and colloids from the water, reducing turbidity. The cured water has a turbidity of less than 0.5 NTU, CODMN of less than 1.5 mg/L, iron content of less than 0.05 mg/L, and SDI of much less than 5. The security filter is installed at the inlet of the reverse osmosis system to avoid fragments bigger than 1μm from entering the reverse osmosis membrane layer. Its filter cartridge is made of polypropylene and needs routine substitute.

- Reverse Osmosis (RO) System : Includes 3 membrane layer housings, each containing 1 Toray SW-RO membrane layer component. The solitary membrane has a desalination price of 99.5%, and the system has a desalination price of 98%, successfully getting rid of liquified salts, microorganisms, and pyrogens from the water. The high-pressure pump is a Danish Danfoss brand, made of duplex steel 2205 material, with a power of 15 kW, capable of providing 4-6 MPa high stress to drive salt water with the reverse osmosis membrane.

- Chemical Dosage System : Include 4 dose devices, specifically made use of for including flocculants, biocides, decreasing representatives, and range inhibitors. The application systems consist of PE-material chemical containers (40L capacity), Italian SEKO brand metering pumps (circulation rate 1L/h, pressure 10.3 bar, material PVDF), and dosing pipelines, which optimize the high quality of the incoming water and secure the reverse osmosis membranes.

- Control System : Makes use of a PLC-based automatic control system, with brand names such as Siemens, Schneider, Omron, or equivalent high quality products. It is outfitted with a 10-inch touchscreen for automatic screen of water supply, flow price, and water quality, featuring self-locking defense and audio-visual alarm system functions, while also sustaining hand-operated operation for practical and trustworthy procedure.

- Various Other Auxiliary Equipments : Consists of a UV steriliser making use of Philips lamps, with a 316 stainless-steel housing, circulation rate of 2 m TWO/ h, and a sterilisation price of 99.99%, guaranteeing risk-free water result; It also consists of a raw water container (10,000 litres) and a freshwater storage tank (2,000 litres), both offered by the customer, made from PE/PP product, and equipped with automatic degree control and handbook drainpipe valves.

4. Solar Seawater Desalination Machine Process

- Salt water is drawn into the raw water storage tank by two stainless-steel 316 centrifugal seawater consumption pumps (flow price 15 m ³/ h, stress 5 bar, head 30 m, power 5.5 kW). 2. The seawater in the raw water container is transported to the pretreatment system via a centrifugal seawater feed pump (circulation price 6 m ³/ h, pressure 4 bar, head 38 m, material SS 316).

- The water first passes through a sand filter to remove big particles, after that sequentially through 5 μm and 1 μm safety and security filters for additional filtration.

- The pre-treated seawater is optimized in top quality through a chemical application system, then pressurised to 4-6 MPa by a high-pressure pump and fed into the reverse osmosis system.

- Under the activity of reverse osmosis membrane layers, seawater is separated right into salt and water, with the item water (freshwater) getting in the freshwater storage tank and the concentrate being discharged.

- The water in the freshwater container is sterilised by a UV steriliser, making it ideal for straight intake.

The entire process is automatically managed by a PLC control system to guarantee steady operation of the tools.

5. Seawater Powered Desalintion Plant Maintenance

- 5μm and 1μm filter cartridges must be changed every 2-3 months, with the details regularity depending on the high quality of the incoming water. If the filter can not fulfill the circulation price required by the reverse osmosis system, it must be replaced immediately.

- Reverse osmosis membranes ought to be changed every 2-3 years. If the top quality of the outcome water wears away or the pressure distinction increases, they ought to be replaced earlier. When replacing them, the pressure vessel have to be opened up for operation.

- Quartz sand and various other filter media need to be changed every 2-3 years to make sure reliable pre-treatment.

6. Project End results

The effective application of this solar seawater desalination machine in the Philippines has actually properly dealt with the alcohol consumption water shortage in seaside locations. The system operates stably, generating 2,000 litres of standard-compliant alcohol consumption water (TDS ≤ 700 mg/L) per hour, meeting homeowners’ day-to-day water demands. Furthermore, by making use of solar energy, the system completely leverages the bountiful local solar power resources, lowering dependence on typical electrical power. This method is both energy-efficient and eco-friendly while also decreasing functional expenses. The system’s automated control system simplifies operation and upkeep, supplying the local area with a long-lasting, secure supply of risk-free drinking water and boosting homeowners’ quality of life.

Dapatkan Solusi Hari Ini!