Project Background

When faced with increasingly serious water shortage and water top quality pollution concerns, a reliable and dependable water filtration system has ended up being an urgent requirement across many industries. Our 40HQ container-based SWRO & BWRO water filtration system, with its impressive efficiency and broad applicability, has actually settled water challenges in multiple regions of the USA, establishing itself as a benchmark case study in the water filtration field.

The system can convert brackish water with a TDS of around 5,000 mg/L right into freshwater with a TDS of ≤ 100 mg/L, and salt water with a TDS of approximately 35,000 mg/L right into safe and clean water with a TDS of ≤ 700 mg/L, fully satisfying human alcohol consumption water demands. Its day-to-day processing capacity is impressive, with a day-to-day processing volume of 25,000 gallons for briny water (BWRO) and 19,000 gallons for salt water (SWRO), making it commonly relevant in different situations such as alcohol consumption supply of water, industrial production, and agricultural irrigation.

What’s the technology of SWRO & BWRO plant?

The core of this water filtration system depends on its advanced reverse osmosis (RO) innovation. Utilizing an unique high-pressure pump, the raw water is pressurised to 12– 70 barG, allowing it to travel through a reverse osmosis membrane layer with pore dimensions as tiny as 0.0001 microns under pressure. Chemical ions, bacteria, fungis, infections, and various other pollutants can not pass through and are released with the wastewater, while just water particles and solvents smaller sized than 0.0001 microns are allowed to travel through. The salt retention rate surpasses 98%, successfully getting rid of liquified salts, colloids, germs, infections, heavy steel ions, and other pollutants from the water.

In regards to energy usage, the tools likewise executes extremely well. The salt water therapy device has a power usage of approximately 28 kW · h, while the brackish water treatment system eats about 16 kW · h, achieving energy-efficient procedure while giving high-efficiency water purification.

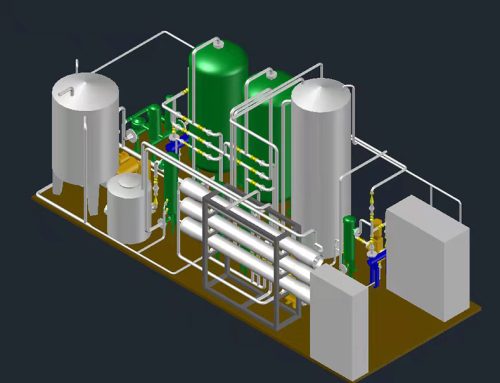

How we design the SWRO & BWRO plant?

The system setup of this tools is extremely detailed, covering all phases from raw water pretreatment to post-treatment of the end product, ensuring that every decline of water undertakes extensive handling.

The pre-treatment system includes disc filters, UV sterilisers, sand filters, turned on carbon filters, safety and security filters, and ozone nano-bubbles. Disc filters get rid of organic pollutants and impurities larger than 100 microns; UV sterilisers utilise particular wavelengths of UV light to destroy the DNA structure of bacteria and viruses, accomplishing sanitation and purification, while also disintegrating natural molecules; sand filters efficiently remove rust, debris, algae, and various other impurities, reducing water turbidity; triggered carbon filters highly adsorb residual chlorine, colour, odour, organic matter, and other impurities, securing the subsequent reverse osmosis membrane layers; ozone nano-bubbles eliminate microorganisms through oxidation, boosting sanitation effectiveness; safety filters better get rid of impurities bigger than 1 micron, supplying defense for the reverse osmosis system.

The reverse osmosis system is furnished with high-pressure pumps, reverse osmosis membrane layers, and stress vessels. Seawater therapy makes use of Danfoss high-pressure pumps and Toray SWRO membrane layers, while briny water therapy uses Grundfos high-pressure pumps, guaranteeing that the raw water goes through reverse osmosis therapy at a suitable pressure.

The supporting system includes a sanitation system and a clean-in-place (CIP) system. The CIP system brings back the penetrate flux of the reverse osmosis membrane when its efficiency declines, expanding the membrane’s service life.

The post-treatment phase once more uses a UV steriliser and a 1-micron titanium filter to extensively get rid of recurring germs, infections, and various other impurities, intercepting toxins in the pipe to ensure the purity and security of the created water.

Widely applicable, meeting multiple water needs

Whether it is desalination of seawater in coastal areas or purification of brackish water inland, this equipment can do it. The treated water quality fully meets the standards for human drinking, and can also be used in industrial production, agricultural irrigation and other fields.

In a coastal industrial park, the equipment successfully converted high-TDS seawater into qualified industrial water, solving the production problems caused by seawater corrosion of equipment in the park and reducing the water cost of enterprises. In an arid area, the equipment treated the local brackish water, providing residents with safe drinking water and improving local living conditions.

If you are facing water quality problems and need an efficient water purification solution, you may wish to pay attention to this 40HQ containerized SWRO&BWRO water purification equipment. For more details, please contact us [email protected]

Dapatkan Solusi Hari Ini!