What is Commercial RO system?

The 1000LPH Commercial Reverse Osmosis (RO) System is a high-efficiency water treatment solution engineered for commercial and industrial applications, delivering up to 1000 liters of purified water per hour. Utilizing reverse osmosis membrane technology, this system effectively removes dissolved salts, heavy metals, bacteria, viruses, and other contaminants to produce water meeting drinking and industrial standards. Typically constructed with stainless steel components and a modular design, the equipment ensures durability, ease of maintenance, and a long service life, meeting pure water demands across diverse industries including food service, healthcare, and manufacturing.

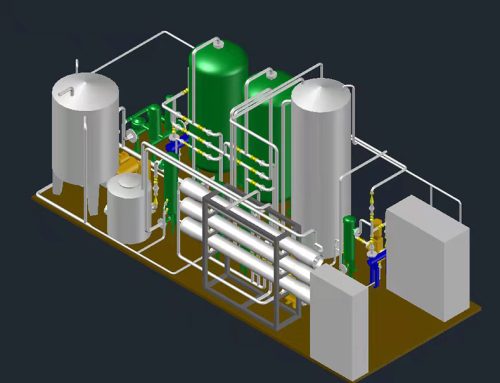

The design philosophy prioritizes high-efficiency production while balancing energy conservation and operational simplicity. The system integrates multi-stage pretreatment units, high-pressure pumps, RO membrane modules, control units, and post-treatment devices, achieving water purification through physical filtration and membrane separation technologies. Unlike small household units, commercial 1000LPH RO systems offer enhanced processing capacity to handle complex water sources like high-hardness groundwater and seawater desalination. They feature automatic cleaning, fault alarms, and remote monitoring capabilities, making them suitable for continuous, high-intensity operation.

From an application perspective, these systems form the core of modern water treatment solutions, providing hotels, food processing plants, hospitals, and laboratories with stable, reliable high-purity water. With technological advancements, many systems now integrate ultraviolet (UV) sterilization or ozone treatment to further ensure water safety. Their flexible configurations allow customization based on actual water usage needs—for instance, dual-stage RO designs enhance desalination rates, while energy-efficient models reduce operational costs.

How is the Technical Specifications for 1000 lph Commercial RO system?

The performance of 1000LPH commercial RO equipment is defined by a series of key technical parameters that determine its suitability and efficiency. The table below summarizes common specifications to provide users with a comprehensive understanding of the system’s capabilities:

| Parameter Category | Detailed Description |

|---|---|

| Water Production Capacity | 1000 liters per hour (customizable upon request, typically ranging from 0.25-50 m³/h) |

| Desalination Rate | ≥98%-99.5%, effectively removes ions, heavy metals, and dissolved solids |

| Recovery Rate | 50%-70%, dependent on feedwater quality and system design (i.e., ratio of product water to feedwater) |

| Operating Pressure | 0.8-1.5 MPa (operating pressure range) |

| Power Requirements | AC 380V / 50Hz / Three-phase (or optional 220V single-phase), power consumption approx. 2.2-3.0 kW |

| Feed Water Quality Requirements | TDS ≤ 1000 mg/L (if source water is municipal tap water); Higher TDS (e.g., brackish water, seawater) requires special design |

| Product Water Quality | Conductivity ≤ 10 μS/cm (typically achievable 1-5 μS/cm), meets drinking water standards |

| System Materials | Stainless steel SUS304 or SUS316 (main frame); Pre-treatment tanks may be FRP (fiberglass reinforced plastic) or PVC |

| Approximate Dimensions | Main unit approx. 1600×1000×1800 mm (L×W×H), flexible design based on site conditions |

| Certifications & Standards | Typically compliant with CE, ISO9001:2015 certification |

These parameters indicate that the 1000LPH RO system can efficiently treat diverse water sources such as tap water, groundwater, brackish water, etc., producing high-quality purified water. The system’s recovery rate and desalination rate are key performance indicators—higher recovery rates minimize wastewater generation, enhancing economic and environmental efficiency. Power and pressure requirements determine the supporting infrastructure needed for installation. When selecting equipment, users should match these parameters to their specific water source conditions (e.g., TDS value, hardness) and product water requirements (e.g., conductivity, intended use) to ensure optimal system operation.

What Are the Components and Functions For Commercial RO system?

The 1000LPH commercial RO system comprises multiple precision components working in concert, each playing a unique and critical role. Together, these components ensure the system’s efficient, stable, and long-term operation. Below are the core components and their functions:

- Pre-treatment System: Pre-treatment serves as the first line of defense for protecting the RO membrane. The quartz sand filter utilizes quartz sand media to effectively remove suspended solids, silt, and colloids from the water, reducing turbidity. The activated carbon filter primarily adsorbs residual chlorine, odors, organic compounds, and certain heavy metals from the water, improving taste and protecting the RO membrane from oxidative damage. For high-hardness water sources, the water softener (ion exchange resin) is essential. It removes calcium and magnesium ions through resin exchange, preventing scale buildup and clogging on the RO membrane surface.

- RO Membrane and Housing: This is the heart of the entire system. The RO membrane employs a semi-permeable membrane with a pore size of just 0.0001 microns. Under high pressure, it allows only water molecules to pass through, while retaining the vast majority of dissolved salts, bacteria, viruses, organic matter, heavy metals, and other impurities, which are discharged with the concentrate. Commercial units typically employ 4040 or 8040 spiral-wound membrane elements, often from internationally renowned brands like DOW Filmtec or Vontron, ensuring desalination rates exceeding 99%. Membrane housings are usually constructed from stainless steel or fiberglass-reinforced plastic (FRP), designed to withstand high pressures (e.g., 450 psi) while securely holding and sealing the membrane elements.

- High-Pressure Pump: This provides the necessary force (pressure) for water to permeate the RO membrane. The pump must pressurize feedwater to 0.8-1.5MPa or higher to overcome osmotic pressure. Its performance and stability directly determine water production and recovery rate. Domestic brands like CNP (Southern Pump Industry) are common choices.

- Control System: Modern commercial RO system typically incorporates an automated control system, often centered around a PLC (Programmable Logic Controller). It monitors critical parameters like flow rate, pressure, and conductivity, automatically executes operations such as flushing and shutdown alarms, and enables remote monitoring. This significantly reduces manual intervention and simplifies operational maintenance.

- Post-Treatment and Disinfection Units: Following RO purification, systems may incorporate UV sterilizers or ozone generators as needed. These eliminate trace bacteria and viruses in the water, ensuring biological safety—particularly crucial for direct drinking applications.

| Component | Primary Function | Common Brands/Types | Replacement/Maintenance Interval |

|---|---|---|---|

| Quartz Sand Filter | Removes suspended solids, silt, colloids | Quartz sand media | 15-18 months |

| Activated Carbon Filter | Adsorbs residual chlorine, organic compounds, odors, improves taste | Granular activated carbon | 15-18 months |

| Water Softener/Ion Exchange Resin | Removes calcium and magnesium ions, prevents scaling | Cation exchange resin | Approx. 2 years |

| Precision Security Filter | Captures particles >5μm, protects RO membrane | 5μm PP filter cartridge | 1-3 months |

| High-Pressure Pump | Provides high pressure required for RO membrane | CNP (Southern Pump Industry) | – |

| RO Membrane Element | Core desalination component, removes ions, microorganisms, organic matter, etc. | Dow Filmtec, Vontron, Toray (4040/8040 type) | Approx. 2-3 years |

| Housing | Contains and seals RO membrane elements, withstands high pressure | Stainless steel SUS304/316 or fiberglass-reinforced plastic (FRP) | Inspect seals as needed |

| Control System | Automates operation, flushing, and alarms | PLC (Programmable Logic Controller) | – |

| Ultraviolet (UV) Sterilizer | Eliminates bacteria and viruses to ensure biosafety | – | UV lamp life: approx. 9000 hours |

The synergistic operation of these components ensures the 1000LPH RO system consistently produces high-quality purified water. Its modular design also facilitates relatively straightforward maintenance and replacement of damaged parts, reducing lifecycle operational costs.

How is Working Principle and Process for Commercial RO system?

The water treatment process of the 1000LPH commercial RO system is a multi-stage synergistic physical separation process, with its core based on Reverse Osmosis (RO) technology. Reverse osmosis is an advanced technique that overcomes natural osmotic pressure by applying pressure, forcing water flow through a semi-permeable membrane to separate contaminants from water. The detailed workflow is as follows:

- Raw Water Pretreatment: Raw water (e.g., tap water, groundwater) is first stored in a raw water tank to buffer and stabilize flow rates. It is then pumped by a pompa air baku to the pretreatment system. Pretreatment typically includes a quartz sand filter, activated carbon filter, and water softener. The quartz sand filter primarily removes suspended particles, silt, and colloids from the water; the activated carbon filter adsorbs residual chlorine, odors, organic compounds, and other contaminants; while the water softener uses ion exchange resin to remove calcium and magnesium ions, reducing water hardness and preventing scaling and clogging of the downstream RO membrane. The pretreated water then passes through a precision filter (typically a 5μm PP cartridge) as a final safeguard, ensuring no minute particles enter and damage the high-pressure pump or RO membrane.

- High-Pressure Boosting and Reverse Osmosis: The pretreated water is pressurized by a high-pressure pump to an operating pressure of 0.8-1.5 MPa (or higher), then fed into the RO membrane assembly. At such high pressure, water molecules are forced through the RO membrane’s minuscule pores measuring just 0.0001 microns. The vast majority of dissolved salts (such as sodium, calcium, and magnesium ions), heavy metals, bacteria, viruses, organic matter, and other impurities cannot pass through. These contaminants are retained and discharged from the system along with a portion of the concentrate. This process effectively separates the feedwater into two streams: one is pure permeate water (product water), and the other is highly concentrated brine (concentrate).

- Post-Treatment and Storage: The pure water produced by the RO membrane may undergo post-treatment based on application requirements. For example, disinfection via ultraviolet (UV) sterilizers or ozone generators eliminates any trace microorganisms present in the water, ensuring its biological safety. Ultimately, the purified water is transported to a pure water tank for storage, awaiting use or distribution to consumption points via a delivery system.

The core principle of the entire workflow relies on the selective permeability of semipermeable membranes dan external pressure driving force. Unlike conventional filtration, RO removes dissolved substances from water, not just suspended particles. The system recovery rate (product water volume/feed water volume) typically ranges between 50%-70%, meaning a portion of concentrated water is produced. This concentrate can be repurposed for flushing, irrigation, or similar applications to enhance overall water resource utilization.

What Are The Advantages For Commercial RO system?

The 1000LPH commercial RO system stands out among water treatment technologies due to its exceptional performance dan reliable design. Its advantages extend beyond superior purification capabilities to encompass operational economy, ease of use, and environmental friendliness, delivering comprehensive value to users.

- High-Efficiency Purification and Stable Water Quality: Utilizing advanced reverse osmosis technology, this equipment achieves a desalination rate of 98% to 99.5%, effectively removing nearly all contaminants including dissolved salts, heavy metals, bacteria, viruses, organic matter, and colloids. The treated water delivers stable, reliable quality with conductivity levels below 10 μS/cm or even lower, fully meeting stringent standards for drinking water, food processing, and industrial production. This consistently high-quality output ensures reliability and uniformity in downstream applications like beverage preparation and laboratory experiments, minimizing risks associated with water quality fluctuations.

- Automated Operation and Low Maintenance Costs: Modern commercial RO systems typically feature PLC automated control systems enabling automatic operation, flushing, shutdown alerts, and remote monitoring, significantly reducing manual intervention. Modular design and long-life core components (e.g., RO membranes lasting 2-3 years) minimize replacement costs. Although initial investment may be higher, its long-term operational efficiency dan low maintenance requirements make the total lifecycle cost more economical.

- Energy Efficiency, Environmental Protection, and Sustainability: Reverse osmosis is a physical water treatment process that minimizes chemical usage, reducing the generation and discharge of chemical waste liquids, making it more environmentally friendly. Through optimized system design (e.g., incorporating energy recovery devices, though not explicitly mentioned in the documentation but common in high-efficiency systems) and enhanced recovery rates (achieving 65%-70%), wastewater generation is effectively minimized while water resource utilization is maximized. This demonstrates the equipment’s commitment to environmental protection and sustainable development alongside economic efficiency.

- Durability, Reliability, and Adaptability: Key structural components typically utilize SUS304 or SUS316 stainless steel, offering corrosion resistance and extended service life to withstand demanding industrial environments. The design accommodates diverse water sources including tap water, groundwater, brackish water (TDS up to 1000mg/L, or higher with specialized configurations). This broad adaptability ensures effective performance across diverse regions and industries.

- Compliance and Safety Assurance: Premium commercial RO plant typically holds international certifications like CE and ISO9001, meeting relevant quality and safety standards to provide users with confidence. Integrated post-treatment units such as UV or ozone disinfection further ensure the biological safety of treated water, making it particularly suitable for direct drinking applications.

These advantages elevate the 1000LPH commercial RO system beyond a mere water treatment tool, positioning it as a vital asset for businesses to enhance product quality, ensure production safety, reduce operational costs, and fulfill environmental responsibilities.

How is The Application For Commercial RO system?

With its high purification efficiency dan consistent water quality, the 1000LPH commercial RO system plays a critical role across numerous industries with stringent water quality requirements. Its output capacity (approximately 1 ton per hour) is well-suited for small-to-medium commercial operations and industrial processes, meeting diverse needs ranging from direct drinking to high-standard production water.

- Food, Beverage, and Catering Industry: One of the most classic applications for RO systems. Bottled water and beverage production requires large volumes of pure water as a base ingredient, with RO water ensuring consistent product taste and contamination-free quality. Food processing (e.g., washing, cooking, ingredient preparation) using pure water extends product shelf life and meets hygiene standards. Hotels, restaurants, and central kitchens rely on it for safe, reliable water in cooking, ice-making, and direct drinking systems—directly impacting consumer health.

- Medical Pharmaceuticals and Biotechnology: This sector imposes extremely stringent purity requirements. Central hospital water systems, laboratory glassware cleaning, and sterilization supply rooms all demand high-quality pure water. In pharmaceutical manufacturing, pure water is essential for drug formulation, production, and liquid products, necessitating compliance with pharmacopeia standards (e.g., Purified Water PW). RO systems are often combined with EDI (Electrodeionization) or ion exchange to produce high-purity water meeting GMP requirements.

- Industrial Manufacturing and Production Processes: Numerous industrial operations rely on pure water to ensure product quality and process stability. The electronics industry (e.g., semiconductor and circuit board production) requires ultrapure water for cleaning to prevent ionic contamination. Boiler feedwater in power generation must undergo advanced purification to prevent scaling and corrosion, enhancing thermal efficiency. Pure water in electroplating, coating, and precision machining prevents surface defects or blemishes on workpieces.

- Agricultural Aquaculture and Aquariums: Though not directly consumed, RO water plays a significant role in these sectors. Aquaculture dan aquariums require water sensitive to ammonia nitrogen, heavy metals, and pathogens. RO treatment provides a clean, safe aquatic environment conducive to biological health. In agricultural irrigation, particularly for hydroponics or high-end flower cultivation, using RO water with low EC values enables precise control of nutrient solution concentration, promoting crop growth.

- Other Commercial & Public Service Facilities: Installing RO systems in public spaces like schools, office buildings, and community water stations provides convenient, safe drinking water. Laundromats using softened pure water enhance cleaning efficiency while reducing scale buildup and chemical usage. – Car Wash Facilities: Using RO water for final rinses prevents water spots on vehicle surfaces, elevating service quality.

The widespread adoption of 1000LPH commercial RO system underscores its value as a critical water treatment solution. Whether meeting stringent compliance requirements or enhancing product quality and operational efficiency, it delivers reliable water quality assurance across diverse industries.

Get The Solution Today!