Project Background and Requirements

The electroplating industry has extremely stringent requirements for water quality. Unlike ordinary industrial water, electroplating bath solutions and water used for cleaning plated parts must meet ultra-high purity standards: even trace impurities can lead to a series of quality issues such as reduced adhesion of the plating layer, surface spots, and weakened corrosion resistance. Especially in modern precision electronic electroplating, residual ion concentrations in water must be controlled at the ppb (parts per billion) level, making traditional ion exchange or single-stage reverse osmosis processes insufficient to meet requirements.

This electroplating plant project is located in an industrial zone, primarily serving automotive parts surface treatment production lines. From the outset of the project design, three core objectives were established: first, to consistently supply 8 tons per hour of ultra-pure water with a resistivity of ≥15 MΩ·cm; second, to address the medium salinity of the raw water with a TDS value of 230, ensuring the system’s desalination rate remains above 98% over the long term; and third, to meet stringent water quality requirements while strictly controlling energy consumption and operational costs.

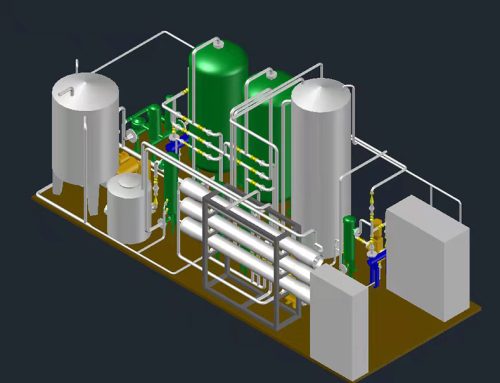

After comprehensive evaluation, we adopted a two-stage reverse osmosis process as the core technical approach. The first-stage RO removes most dissolved salts, while the second-stage RO performs deep purification. This sequential purification design ensures the final water quality while extending the lifespan of core membrane components through staged processing.

Raw Water Quality

The project’s water source is municipal tap water with a TDS value stable around 230 mg/L, falling within the medium salinity range. Water quality analysis reports indicate that calcium and magnesium hardness ions account for over 40% of the total, with trace amounts of iron, manganese, and organic pollutants also detected. These water quality characteristics pose potential risks in reverse osmosis treatment: hardness ions tend to form scale on the membrane surface; colloidal organic matter can cause membrane pore blockage; and residual chlorine can oxidize and damage the active layer of polyamide RO membranes.

Electroplating processes impose extremely stringent requirements on key water quality parameters: in addition to strictly controlling conductivity (≤5 μS/cm), specific ion concentrations affecting coating quality must be reduced to the ppb level. For example:

- Chloride ions > 0.1 ppm accelerate the decomposition of precious metal electroplating solutions

- Silicate > 0.05 ppm will cause fog spots on the plating layer

- Bacterial residues will contaminate the plating tank and cause product mold growth

To address this challenge, the system design must not only achieve efficient desalination but also establish multiple safeguards: intercepting colloidal particles at the source, neutralizing residual chlorine threats, and inhibiting scaling tendencies, ultimately ensuring the long-term stable operation of the dual-stage RO system.

Two-stage RO process

1. MMF+MCF pretreatment

The multi-media filter (MMF) serves as the system’s “frontline guardian,” filled with dual-layer quartz sand filter media (upper layer 0.6–1.2 mm, lower layer 2–4 mm) to form a gradient filtration structure. As water flows downward through the filter bed, suspended particles are progressively retained, with turbidity consistently controlled at ≤1 NTU. When the pressure difference exceeds 0.05 MPa, the system automatically initiates air-water combined backwashing, with high-pressure water flowing upward to flush the filter bed, restoring filtration performance.

The subsequent activated carbon filter (MCF) is loaded with coconut shell activated carbon filter media, which adsorbs residual chlorine, organic matter, and some heavy metals through its highly developed microporous structure. Here, high-adsorption activated carbon with an iodine value ≥950 mg/g is used to ensure that the residual chlorine concentration in the effluent is ≤0.1 ppm, completely eliminating the threat of oxidants to the subsequent RO membrane. The activated carbon layer also removes off-colors and odors, improving water quality sensory indicators and creating ideal feedwater conditions for the reverse osmosis system.

2. Flocculation-Scale Inhibition Synergistic Chemical Dosage

Two dosing systems are installed in the post-treatment section, injecting specialized coagulants and scale inhibitors. The coagulant uses a PAC (poly aluminum chloride) formulation, which completes micro-flocculation reactions in the pipeline mixing section, aggregating nano-sized colloidal particles in the water into larger flocs for easier subsequent interception. This process reduces the SDI index to ≤3, significantly alleviating the pollution load on the RO membrane.

The scale inhibitor dosing process uses a high-efficiency organic polymer formulation with molecular structures containing multiple chelating groups, enabling the formation of soluble complexes with calcium and magnesium ions. Even when the feedwater is concentrated fourfold, the scale inhibitor effectively inhibits the precipitation of calcium carbonate and calcium sulfate crystals, boosting system recovery rates to over 65%, far exceeding the 50% upper limit of traditional softening processes.

3. Security filtration: the protective barrier of the membrane system

Before entering the RO membrane, the water flows through a 5μm precision security filter. This stage uses a polypropylene melt-blown filter cartridge to completely retain any particles or activated carbon debris that may have been missed by the pretreatment process. As the final mechanical barrier, the security filter protects the high-pressure pump and RO membrane from damage by hard particles, and changes in its pressure differential serve as an important indicator of the effectiveness of the pretreatment process.

4. Two-Stage RO Deep Desalination: Core Purification Unit

The first-stage RO system is equipped with high-efficiency anti-pollution composite membranes, operating at a pressure of 1.0–1.5 MPa, with a desalination rate consistently above 97%. The high-pressure pump incorporates a PX energy recovery device, directly transferring concentrate water pressure to the incoming water, significantly reducing energy consumption. The first-stage product water conductivity can be reduced to below 10 μS/cm, meeting the requirements for general cleaning water.

The second-stage RO system employs boron-selective specialty membranes to specifically remove weakly ionized substances such as boron and silicon that are difficult to remove in the first stage. This stage operates at a pressure of approximately 1.0 MPa, using the first-stage purified water as feedwater to avoid contamination risks, thereby extending membrane lifespan by over 30%. The conductivity of the secondary RO product water is stabilized below 2 μS/cm (resistivity ≥ 5 MΩ·cm), with core indicators meeting the standards for electroplating tank solution preparation.

Key Performance Indicators Comparison Table for Electroplating Pure Water Systems

| Parameters | Raw water | One pass ro | Two pass ro | Electroplating Standards |

|---|---|---|---|---|

| TDS (mg/L) | 230 | ≤10 | ≤1 | ≤5 |

| Conductivity (μS/cm) | 480 | ≤10 | ≤2 | ≤5 |

| Residual Chlorine (mg/L) | 0.5 | <0.01 | <0.01 | <0.1 |

| SiO₂ (ppb) | 1200 | ≤100 | ≤20 | ≤50 |

| Hardness (mg/L) | 95 | ≤2 | ≤0.1 | ≤0.5 |

5. Product Water and Water Supply System

An 8m³ food-grade PE water tank serves as the product water storage unit, equipped with a nitrogen protection system to prevent carbon dioxide from the air from dissolving and causing the conductivity to rise. The water tank level is interlocked with the RO system for control; high level automatically shuts down the system, and low level triggers the system to replenish water.

The water supply system employs constant-pressure variable-frequency control to ensure stable water pressure at the end-of-line water points in the workshop at 0.3 MPa ± 0.02. The piping design forms a closed-loop circuit to prevent microbial growth in dead zones. The terminal is equipped with UV sterilization + 0.2 μm precision filters to ensure that each drop of water meets the microbial standards for pharmaceutical injection water as specified in the pharmacopoeia.

6. CIP Online Cleaning

The system integrates a CIP in-place cleaning device, including a cleaning tank, heater, circulation pump, and dedicated piping. When the RO membrane pressure differential increases by 15% or the standardized water production decreases by 10%, the system automatically prompts the need for cleaning. Customized cleaning solutions are adopted for different types of contamination:

- Colloidal contamination: pH 2-3 citric acid solution

- Biological contamination: hydrogen peroxide + surfactant mixture

- Inorganic scaling: 2% EDTA tetrasodium salt solution

After cleaning, the membrane flux recovery rate is ≥90%, extending membrane lifespan to over five years.

System Advantages

1. Water Quality Benefits

The core value of this system lies in its exceptional water quality. According to third-party testing, the resistivity of secondary RO water is stable at 5–8 MΩ·cm (conductivity 0.2–0.125 μS/cm), far exceeding the 1 μS/cm standard required by the electroplating industry. The removal rate of special ions such as silicon and boron, which significantly affect coating quality, reaches 99.5%, completely eliminating white spots on the surface of plated parts. The total bacterial count in the final output water is <1 CFU/ml, eliminating the risk of plating solution degradation caused by biological contamination.

After adopting this system, a certain electroplating production line reduced product defect rates from 2.3% to below 0.15%, and the pass rate for salt spray tests on chrome-plated automotive exterior parts reached 99.8%, earning A-level supplier certification from multiple original equipment manufacturers (OEMs). Improved water quality also extended the service life of precious metal electroplating solutions, with the replenishment cycle for cyanide gold plating tanks extended from 3 weeks to 8 weeks, saving 270,000 yuan per tank annually.

2. Energy Saving and Consumption Reduction

Despite using a two-stage RO process, the system achieves low-energy operation through three major energy-saving designs:

- PX Energy Recovery Device: Directly transfers concentrate water pressure to the feed water, reducing high-pressure pump energy consumption by 40%

- Variable Frequency Control Technology: Automatically adjusts pump frequency based on water temperature and quality to avoid unnecessary energy consumption

3. Inter-stage Energy Coupling

The actual operating power of the entire system is only 17 kW, with electricity consumption per ton of water reduced to 2.125 kWh, significantly below the industry average of 3 kWh. Compared to traditional ion exchange processes, this reduces annual consumption of acid/alkali regeneration chemicals by approximately 86 tons and lowers hazardous waste treatment costs by 350,000 yuan.

Challenges

1. Biofouling Control

Biological fouling of reverse osmosis membranes is a major industry challenge, especially in electroplating facilities where the air is rich in metal dust, which easily forms biofilms with microorganisms. This project innovatively employs a triple antimicrobial barrier: UV sterilizers are installed in the pretreatment section to inactivate suspended microorganisms; sodium bisulfite is added to the RO feedwater to eliminate residual oxidants; and the product water piping uses pulsed ozone disinfection technology for automatic monthly sterilization cycles. Operational data shows that this solution extends the membrane biofouling frequency from the industry average of 6 months to 22 months.

2. Concentrate Water Salt Balance

The concentrate water produced by the two-stage RO system has a salt content as high as 3,000 mg/L, and traditional discharge is both wasteful and polluting. The project developed concentrate water quality reuse technology: the first-stage concentrate water (TDS approximately 1,200 mg/L) is moderately softened and used as cooling tower makeup water; Secondary concentrate water (TDS approximately 3,000 mg/L) is transported to the pre-treatment section of the electroplating process, where it is used for the first rinse in the tertiary rinsing stage following acid washing. This solution achieves an overall water resource utilization rate of 85%, far exceeding the industry average of 60%.

3. Stable operation

To address the threat of voltage fluctuations to the precision RO system, a dual-power supply + UPS uninterruptible power supply has been specially configured to ensure stable operation of the high-pressure pump. The membrane housings are arranged in a three-stage configuration to optimize water flow distribution and reduce short-circuiting. To address low-temperature issues in winter, plate heat exchangers have been added to the pretreatment section to maintain the RO feedwater temperature at ≥20°C, ensuring stable water production.

รับโซลูชั่นวันนี้!