تكنولوجيا تحلية المياه converts seawater into potable or usable freshwater by removing salts and impurities. This technology is characterized by its independence from flooding, migration, political bias, and climate constraints. Its water supply reliability and quality remain unaffected by geographical location, environmental conditions, climate patterns, or social factors. With freshwater resources dwindling due to global warming, desertification, and environmental pollution, coupled with a growing global population, desalination has advanced rapidly in recent years. It has proven to be a reliable and effective water supply option, serving as a vital solution for addressing resource shortages in coastal regions and offshore islands.

What are the desalination technologies?

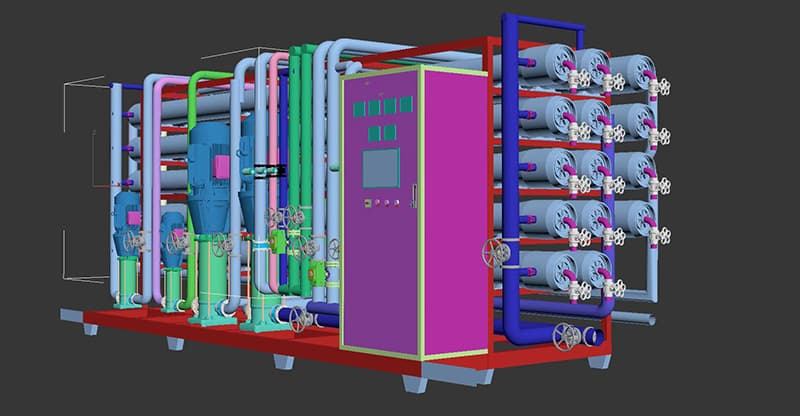

Currently, desalination primarily employs two major categories of technology: thermal methods (distillation) and ro membrane methods (reverse osmosis).

Thermal methods include Multi-Stage Flash (MSF) and Multi-Effect Distillation (MED). MSF involves introducing heated seawater into a low-pressure vessel for instantaneous evaporation and condensation; MED utilizes multiple passes of steam to sequentially heat and evaporate seawater. Thermal methods are mature and highly safe but consume significant energy.

Membrane methods primarily involve reverse osmosis (RO) technology, which uses high pressure to force seawater through a semi-permeable membrane, retaining salts while allowing freshwater to pass through. The core energy consumption of RO lies in the electricity used by high-pressure pumps, accounting for 40%-50% of costs. However, its overall energy consumption is relatively low (approximately 3-4 kWh/cubic meter), making it the fastest-growing seawater desalination technology.

What is the cost seawater desalination per gallon?

Seawater desalination costs vary significantly based on technology, scale, and geographic location. According to international research and practical experience, costs typically range from $0.5 to $3 per cubic meter

In China, reverse osmosis desalination costs approximately $0.61-$1.22/ton, while thermal desalination technologies cost $0.92-$1.83/ton. Converted to cost per gallon, this equates to approximately o $0.002–$0.005 per gallon.

Internationally, desalination costs exhibit greater diversity. In the Middle East, economies of scale and subsidies can reduce costs to as low as $0.31-$0.61/ton. Recent international desalination project bids have even reached 0.4-0.6 USD/cubic meter. Certain Saudi projects utilizing solar coupling technology achieve costs as low as 0.4 usd/ton.

What are the construction costs of global desalination plants?

Below is a comparison of construction costs for 15 representative desalination plants:

| Project Name | Region | Capacity (10^4 m³/day) | Technology | Completion Year | Construction Cost |

|---|---|---|---|---|---|

| Shubaybah 3 | Mecca, Saudi Arabia | 128.2 | MSF, RO | 2019 | $821 million |

| Sorek | Tel Aviv, Israel | 117.2 | RO | 2023 | $1.5 billion |

| Ras Al-Khair | Saudi Arabia | 103.6 | MSF, RO | 2014 | $1.76 billion |

| Tawila | Abu Dhabi, UAE | 90.92 | RO | 2022 | $890 million |

| Jubail 3A Industrial Park | Saudi Arabia | 60 | RO | 2022 | $650 million |

What are the production capacities and technological features of the world’s top five desalination plants?

- Ras Al-Khair, Saudi Arabia: Daily capacity of 1.036 million cubic meters, utilizing a combined MSF and RO process with integrated power generation, commissioned in 2014.

- Tawila, UAE: Daily capacity of 909,200 cubic meters, pure RO technology, operational since 2022, with costs as low as $0.0018 per gallon.

- Shuaiba 3, Saudi Arabia: Daily capacity of 1,282,000 cubic meters, expanded to become the world’s largest, combining MSF and RO technologies.

- Saudi Arabia Jubail: Daily capacity of 800,000 cubic meters, combined heat and power (CHP) model, utilizing multi-effect distillation (MED) technology.

- UAE Um Al Quwain: Daily capacity of 682,000 cubic meters, pure RO process, constructed by China Gezhouba Group, operational since 2022.

Current Global Application Status of Desalination Technologies

- Middle East Region: Countries like Saudi Arabia and the UAE rely on desalination for over 90% of their drinking water needs. Saudi Arabia hosts the world’s largest cluster of desalination plants.

- Singapore: Utilizing advanced RO technology, desalinated water accounts for 30% of total water supply, becoming a core water source.

- China: Coastal cities like Shanghai and Tianjin promote desalination for industrial cooling and municipal use, with annual capacity exceeding one million tons.

- Australia: Western Australia builds large-scale desalination plants to address water shortages in arid climates.

What Factors Influence Desalination Costs?

Seawater desalination costs are influenced by multiple factors, primarily including:

Energy Expenses: This constitutes the largest cost component. For reverse osmosis, electricity costs account for 41.49% of total expenses; for multi-effect distillation, steam costs represent 34.76% of total costs. A 20% reduction in electricity prices lowers reverse osmosis water production costs by 11.86% per ton.

Capital Investment: Including equipment procurement and construction costs, this constitutes a significant portion of total expenses. Equipment and tool purchases account for approximately 58% of capital investment. A 20% reduction in capital investment can lower desalination production costs by 14.68%.

Economies of Scale: Larger projects achieve lower unit costs. Projects with higher daily production volumes exhibit reduced desalination costs per ton of water.

Geographic Location and Water Quality: Higher costs occur in areas with poor seawater quality or limited access to low-cost energy. Coastal regions generally have lower costs, while inland areas tend to be more expensive.

Technology Selection: Reverse osmosis typically offers lower costs than thermal methods. However, thermal costs can be significantly reduced if inexpensive steam or waste heat resources are available.

How Much of the Cost is Attributed to Energy Consumption?

Energy consumption constitutes the primary component of desalination costs. For reverse osmosis desalination processes, electricity consumption ranges from 3-5 kWh per ton of water, with electricity expenses accounting for 40%-50% of total costs.

For multi-effect distillation (MED) desalination processes, electricity consumption is 0.9-1.5 kWh per ton, but steam energy is also required. When steam is sourced from exhaust steam or waste heat, steam costs become negligible, substantially lowering water production expenses.

The Rabigh Phase IV desalination project in Saudi Arabia employs advanced technology, reducing electricity consumption to 2.78 kWh per ton of produced water. At Saudi Arabia’s industrial electricity rates, the cost to desalinate one ton of seawater is only $0.3.

What are the investment costs for large-scale desalination projects?

Large-scale desalination projects entail substantial investment costs. These vary significantly depending on technology and scale:

Reverse osmosis desalination projects require investments of 1,000–1,500 USD per ton of water; Investment for Multi-Effect Vacuum Distillation (MEVD) desalination projects ranges from 1,200 to 2,000 USD per ton of water.

Specific project examples include:

- Israel’s Sorek Phase II desalination project, with an investment of $1.5 billion and a designed daily capacity of 820,000 tons.

- Saudi Arabia’s Rabigh Phase IV desalination project, with an investment of $0.7 billion and a daily freshwater production of 600,000 tons.

The Jubail 3A desalination project in Saudi Arabia, constructed by China, has a daily capacity of 600,000 tons with an investment of $650 million; the Rabigh 3 project similarly produces 600,000 tons daily at a cost of $690 million.

How does the economics of desalination compare to traditional water sources?

Desalination costs are becoming increasingly competitive against conventional water sources. In China, the average cost per ton of desalinated water ranges from 0.8 to 0.2 usd, significantly higher than the 0.8 to 0.9 usd seen in advanced overseas projects. However, it remains lower than the water transfer costs in some water-scarce regions.

Qingdao has established a desalination capacity exceeding 230,000 tons per day. Baifa Desalination Co., Ltd. charges an average industrial water usage cost of 0.9 usd/ton and a municipal usage cost of 0.75 usd/ton. The Dongjiakou Desalination Plant charges 0.65 usd per ton for its desalinated water.

While seawater desalination cannot yet fully replace inter-basin water diversion projects like the South-to-North Water Diversion Project, it holds unique advantages in coastal regions. It serves as a supplementary water source to meet some industrial and domestic water demands. With technological advancements and increased scale, desalination costs are expected to decline further, enhancing its competitiveness against traditional water sources.

Will desalination costs continue to decline in the future?

Yes, desalination costs are projected to keep falling. Over the past two decades, the electricity consumption required to treat one cubic meter of seawater using reverse osmosis technology has dropped from 5 kWh to under 3 kWh. Between 1999 and 2017, costs for reverse osmosis and low-temperature multi-effect distillation decreased by approximately 29.75% and 36.97%, respectively.

Key avenues for future cost reduction include:

Technological Innovation: Developing new energy-efficient desalination technologies to enhance overall quality and core competitiveness. Examples include research into graphene membranes and forward osmosis (FO) systems.

Domestic Equipment Production: Achieving domestic manufacturing of desalination equipment will reduce engineering costs for domestic desalination plants by 20-30% compared to foreign counterparts, lowering corresponding desalination costs by 10-15%.

Energy Optimization: Significantly reducing energy costs by utilizing renewable energy sources (photovoltaic, wind power) for power generation, harnessing industrial waste heat (e.g., flue gas from power plant chimneys, cooling exhaust from steel mills), and developing integrated “wind power-desalination-hydrogen production” solutions.

Economies of Scale: As project scales expand, both unit investment and operational costs will continue to decrease. With global daily desalination capacity projected to reach 250 million cubic meters by 2030, economies of scale will become increasingly pronounced.

In summary, seawater desalination costs have fallen from previously prohibitive levels to competitive rates. Future technological advancements and increased scale are expected to drive further cost reductions, positioning desalination as a key solution to global water scarcity challenges.

Get A Quote Today!