مقدمة

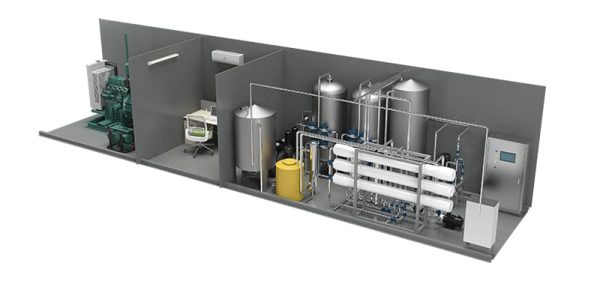

The preparation of seawater reverse osmosis (SWRO) is the core of modern seawater desalination technology, which converts seawater into fresh water for drinking or industrial applications through a series of closely coordinated components. The selective discrimination characteristics of this fraudulent semi permeable membrane, which forms a distinction between salt and water under pressure, have become an important solution to the problem of water scarcity in coastal areas.

How does SWRO plant work?

Reverse osmosis technology is a membrane separation process driven by pressure difference, which focuses on applying an external force higher than the osmotic pressure of seawater to make water molecules pass through the semi permeable membrane in the opposite direction of natural permeation, while impurities such as dissolved salts and organic matter are retained. In seawater desalination applications, the operating pressure usually needs to reach 5.0-7.2 MPa to overcome the high osmotic pressure of seawater (about 2.5-3.0 MPa).

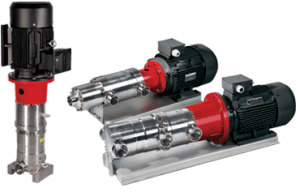

How does a high-pressure pump provide the power required for reverse osmosis?

The high-pressure pump is the “heart” of reverse osmosis, responsible for providing the pressure energy required for the membrane separation process! According to different staffing scales, there are various forms of high-pressure pumps: large systems (such as daily production of tens of thousands of tons) often use horizontal open or multi-stage series centrifugal pumps, with a single pump flow rate of up to 220m ³/h, while small and medium-sized staffing is suitable for plunger pumps, which have stable output pressure and comply with high characteristics;

How can energy recovery device achieve energy conservation and consumption reduction?

The energy recovery device (ERD) is the key to reducing the operating cost of reverse osmosis systems. It can transfer the pressure energy of high-pressure concentrated seawater to the feed seawater, and the acceptance efficiency can reach over 94%. Main types of collection: – Pressure Exchanger : Suitable for large and medium-sized equipment through direct contact pressure transmission – Turbo type recovery device : uses centrifugal principle to convert energy, compact structure – Valve controlled system : By controlling the directional valve through a program, the pressure can be easily controlled, and the processing capacity range is wide (2-200m ³/h) These devices can reduce the collective energy consumption of reverse osmosis systems by about 30-40%, which can save more than 25000 kWh of electricity per day for a seawater desalination plant with a daily output of 50000 tons; The latest rotor type energy recovery assembly adopts fluid self balancing technology and does not require external driving components. The single machine pressure can reach 6.9 MPa, and the mixing rate is controlled between 3-5%!

How to protect ro membrane in pre-treatment?

Pre treatment is a key step in ensuring the long-term stable operation of reverse osmosis membranes, with the aim of removing suspended solids, microorganisms, and potential pollutants from seawater. The example pretreatment process includes a combination of physical filtration and chemical treatment. The following table summarizes the main pretreatment components and their functions:

| Component Name | Main Effectiveness | Technical Indicators |

|---|---|---|

| Multi media filter | Removal of suspended solid particles | Quartz sand+activated carbon combination, removal rate of 95% |

| Precision security filter | Fine filtering of small particles | 5 μ m pore size, 99.9% blocking rate |

| UV sterilization device | inactivating microorganisms | combined with oxidants, microbial indicators<1CFU/mL |

| Softening resin exchanger | Reducing water hardness | Lowering hardness to below 1.0mol/L |

The design of pre-treatment preparation needs to consider the characteristics of the raw water quality. For example, for seawater with high algae content, a sodium hypochlorite generator should be used for sterilization and algae removal, and frequent reverse polarity technology should be used to prevent electrode scaling! Improved pretreatment can extend the lifespan of reverse osmosis membranes by over 40%;

How do ro membrane and post-treatment systems achieve final purification?

The reverse osmosis membrane element is the core of the عملية تحلية المياه. Modern seawater desalination membranes use composite polyamide materials, with a desalination rate leading 99.5% and a salt permeability rate of less than 0.3g/m ² · d. Membrane components are assembled in pressure vessels, usually 6-8 components are connected in series to form a pressure vessel. For a capacity of 15m ³/h, 3-4 pressure vessels are generally configured to work in parallel.

The post-processing preparation aims to adjust the quality of the product water to make it suitable for the application method. Mainly includes: -Re mineralization control: adding calcium and magnesium ions through a calcite contactor to regulate the taste and corrosiveness of water – pH adjustment : Inject carbon dioxide or alkaline solution to stabilize the pH within the range of 7.0-8.5 -Disinfection control: Adopting ultraviolet or trace chlorine disinfection to ensure microbial safety The post-treatment reduces the total dissolved solids (TDS) of the produced water to 200-500mg/L, which fully complies with the “Sanitary Standards for Livelihood Drinking Water” (GB5749)!

How to ensure the operation of the control system?

The swro plant integrates PLC intelligent control module to achieve real-time monitoring and automatic adjustment of parameters such as pressure and conductivity! The key functions include: – Automatic cleaning program : intelligently runs membrane cleaning based on transmembrane pressure difference changes -Accurate control of drug dosage: precise control of the amount of scale inhibitors and reducing agents added – Long distance monitoring function : supports viewing operational data on mobile devices, and fault diagnosis programming can predict component loss cycles The intelligent control system improves maintenance efficiency by 60% and can optimize operating parameters through data analysis to minimize energy consumption!

Conclusion

The preparation of swro is a highly integrated system, which provides energy from high-pressure pumps to energy-saving optimization of energy recovery devices, and achieves efficient and reliable seawater desalination processes through tight pretreatment, intelligent control, and the cooperation of various components. With the development of materials science and automation capabilities, the energy consumption of reverse osmosis preparation will be further reduced, and the application scope will continue to expand, providing key technical support for addressing the global water shortage problem.

احصل على حل اليوم!