As industrial development continually pursues lower investment costs and shorter construction cycles for water treatment systems, containerized water treatment plant has emerged as an increasingly popular solution. Compared to traditional on-site constructed buildings, containerized systems offer multiple advantages including high cost-effectiveness, rapid deployment, and minimal on-site installation requirements. However, when comprehensively evaluating site planning, material selection, design lifespan, and technical specifications, their total investment and lifecycle costs may not always represent the optimal choice. A specialized assessment of treatment process requirements, expected objectives, and building codes helps determine whether a containerized treatment system is suitable for your project.

How Do Containerized Solutions Enhance Water Treatment Efficiency?

How Do Containerized Solutions Enhance Water Treatment Efficiency?

The core strengths of containerized treatment systems lie in their high modularity و flexible configuration capabilities. Systems for complex processes can easily modify components like doors, windows, access hatches, and connection interfaces. They also meet aesthetic and material requirements for non-industrial environments (e.g., municipal, parks, or schools).

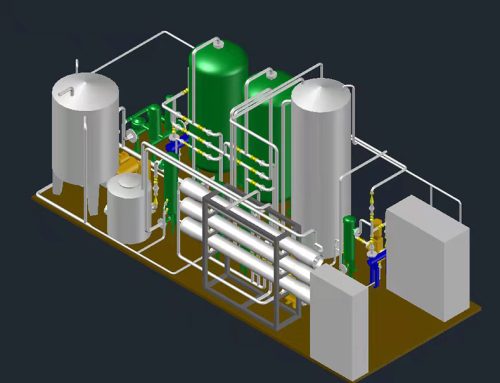

Depending on treatment requirements, modular units like reverse osmosis (RO), nanofiltration (NF), ultrafiltration (UF), chemical dosing, and pumping systems can be integrated into containers. Common configurations include:

- Convenient lighting and power outlets

- Additional personnel access doors

- Soundproofing facilities

- Chemical safety storage and protection devices

- Chemical-resistant floor and wall coatings

- Safety shower stations

- HVAC systems

- Laboratory testing zones

- Explosion-proof electrical equipment (for hazardous locations)

- Centralized Electrical and Control Systems

Where are containerized water treatment plants most suitable?

Containerized integrated sewage treatment equipment has a wide range of applications, covering various domestic sewage and similar industrial organic wastewater treatment:

- Residential communities, villages, towns, office buildings, shopping malls, hotels, restaurants, sanatoriums, government agencies, schools, hospitals: Addressing daily domestic wastewater treatment needs, particularly suitable for remote areas with relatively limited technical resources.

- Highways, railways, factories, mines, tourist attractions: Meeting wastewater treatment demands for temporary or fixed sites.

- Small-to-medium scale industrial organic wastewater from slaughterhouses, seafood processing, food production, etc.: Treats similar industrial organic wastewater to meet National Comprehensive Wastewater Discharge Standard Grade B.

- Emergency water supply or distributed treatment scenarios: Its compact structure and rapid deployment capability make it highly suitable for emergency needs.

- High-capacity treatment scenarios: Flexibly adapts to varying treatment scales through parallel or series connection of multiple units.

How cost-effective is the containerized water treatment plant solution?

While the base container cost may seem low, customization-related additional expenses can quickly exceed initial equipment costs, potentially making the total cost higher than traditional buildings.

Large treatment units like clarifiers, dissolved air flotation (DAF), gravity filters, and sludge treatment systems may require specialized layouts such as stackable designs or removable partitions. Additionally, configurations like wall panel insulation, interior lighting, electrical systems, and HVAC can add tens of thousands of dollars to containerized systems.

| Feature Comparison Dimension | ISO Container | Custom Steel Structure | Nomal Steel Structure |

|---|---|---|---|

| Initial Cost | Relatively low, ample supply | Higher, typically 2-3 times standard container | Variable, often higher |

| Delivery Lead Time | Short, readily available | Longer | Long, involves civil construction |

| Customization Flexibility | Moderate, can be modified but constrained by standard dimensions | High, can be built to project-specific dimensions and requirements | High, can be fully designed to meet specific needs |

| Transportation Ease | High, designed for multimodal transport | May be complex, requiring special arrangements | Not applicable |

| Suitable Treatment Scale | Small to medium systems, or as modules for large systems | Adaptable for medium to large systems | All scales |

| Scalability | Achieved through parallel/series connection of multiple units | May require redesign | Easily scalable, but higher cost and time |

| Maintenance Accessibility | Limited; constrained internal space may complicate maintenance | Can be designed more spacious, but limitations may persist | Excellent; ample space for easy maintenance |

What are the potential challenges of containerized water treatment plants?

The significant advantage of containerized systems lies in their ability to substantially reduce on-site installation requirements. The entire system undergoes prefabrication and assembly at the factory, with all piping connections, wiring installations, and functional testing completed before site delivery. In most cases, contractors only need to pour concrete foundations, position the containers, connect external piping, and complete power connections. The time from equipment delivery to producing treated water is typically just a few days, drastically shortening project timelines.

However, their greatest drawback often manifests during the long-term operation and maintenance phase. Traditional water treatment buildings provide ample space for overhead pipe racks, cable trays, buried pipelines, and dedicated electrical rooms, whereas container interiors are inherently limited. Routine maintenance like filter cartridge replacement or sensor calibration remains feasible with proper planning. However, replacing reverse osmosis membranes or servicing major components like pumps or motors becomes extremely challenging in confined spaces, often requiring the removal of surrounding equipment. While adding more containers can alleviate space constraints, this brings us back to the investment versus benefit trade-off. Additionally, region-specific regulations must be considered, as container systems may require extra investments to meet fire safety, seismic resistance, and noise control requirements.

How to Effectively Implement Containerized Water Treatment Plant Projects?

If opting for a containerized solution, successful implementation hinges on several key factors:

- Precise Needs Assessment and Planning: Clearly define treatment processes, water volume/quality requirements, automation levels, and future scalability. This forms the basis for choosing standard containers or custom enclosures.

- Attention to Detail in Design: Collaborate with experienced suppliers to optimize internal layouts, equipment selection, and material choices. Maximize space utilization (e.g., liquid cooling technology can save 25% space) while ensuring accessible maintenance pathways.

- Strict Compliance with Regulatory Standards: Proactively engage with local regulatory bodies to ensure designs meet all safety, environmental, and building code requirements, avoiding costly retrofits and delays.

- Developing Long-Term O&M Strategy: Incorporate maintenance needs during design, planning for spare parts storage, personnel training, and potential remote monitoring systems (IoT sensors enable remote operations) to reduce total lifecycle costs.

Conclusion

Containerized water treatment plants demonstrate significant value across industrial water treatment, rural sewage management, and emergency water supply due to their modularity, mobility, and rapid deployment. Their cost-effectiveness and time-saving advantages in specific scenarios are particularly notable.

However, their suitability is not absolute. The decision hinges on a comprehensive evaluation: carefully weighing their rapid deployment capability and potential cost-effectiveness against long-term maintenance challenges and spatial constraints. Ultimately, the optimal solution is the one that best balances the project’s short-term objectives with its long-term operational requirements.

احصل على حل اليوم!