UV Water Sterilizer Ultraviolet Disinfection

- Low-pressure ultraviolet lamp technology service life in 9000 hrs

- high purity quartz sleeve, and ultraviolet ray through above 90%

- 304 stainless steel , the reactor wall special polishing processing

- Equipment with the United States NSF TITLE no. 55 standard design

KYsearo UV water sterilizer adopts internationally leading high-intensity odorless ultraviolet sterilization technology. Its core component, the ultraviolet lamp tube, can emit C-band ultraviolet light with a wavelength of 253.7 nanometers. This band can effectively penetrate the microbial cell wall, destroy its DNA/RNA structure, and cause it to lose its reproductive ability, thereby achieving efficient and rapid sterilization effect

Power: 300w

In and out of the caliber: DN80

Laboratory equipment pressure: 1.0MPA

Equipment under pressure: 0.6MPA

Installation dimensions: 900*133mm

Rated voltage: AC480 v + 5%,

Frequency: 60 HZ

How dose an UV water sterilizer work?

The ultraviolet water sterilizer is an efficient water control device that mainly destroys the genetic material of microorganisms in water by emitting specific wavelengths of ultraviolet light, thereby achieving the purpose of disinfection. Below, we will provide a detailed explanation of its mission principles, key components, advantages and limitations, as well as application precautions!

The working principle of the UV water sterilizer

The mechanism of ultraviolet water disinfectors is to use short wave ultraviolet radiation, especially the UVC band around 253.7 nanometers; This wavelength of ultraviolet radiation has high energy and can be strongly absorbed by the DNA or RNA of microorganisms such as bacteria and viruses.

It is worth noting that in addition to the 253.7nm wavelength mainly used for disinfection, ultraviolet radiation with a wavelength of 185nm can also decompose organic molecules in water, oxidize them to carbon dioxide, and help reduce the total organic carbon content in water.

The components and task processes

A sample UV sterilizer consists of the following key components working together:

-UV tube: It is a set of light sources, and its lifespan is usually around 8000 to 12000 hours! As the application time increases, its ultraviolet output intensity will gradually decrease and needs to be replaced on schedule;

-Quartz sleeve: Used to isolate the lamp tube from water, protect the lamp tube from water flow and temperature changes. High purity quartz glass typically requires a transmittance of over 85% for 253.7nm ultraviolet radiation, and high-quality glass can reach 90% or even higher.

-Stainless steel reaction chamber: It is usually made of 304 or 316 stainless steel, and the inner wall is polished to promote UV reflectivity, making the UV radiation inside the chamber more uniform and avoiding blind spots!

– Ballast and Control System: Provides static power to the lamp tube and monitors its operating status, such as accumulated working hours, UV intensity, etc;

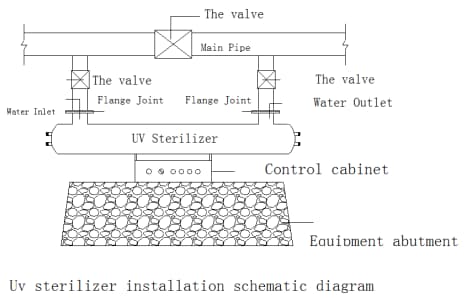

The basic working process is as follows: the water to be treated flows into the stainless steel reaction chamber from one end, flows in a turbulent state around the ultraviolet lamp tube inside, receives sufficient dose of ultraviolet radiation, and the disinfected water flows out from the other end.

What are the advantages of UV water sterilizer?

What are the advantages of UV water sterilizer?

Efficient and broad-spectrum sterilization: With a sterilization rate of over 99.9%, it can quickly inactivate various microorganisms such as bacteria, viruses, algae, etc. in water. Radiation can take effect in just a few seconds, and microorganisms will not develop drug resistance.

Safe and pollution-free: As a physical disinfection method, this device does not add any chemical agents, so it will not change the physical and chemical properties of water, eliminating the risk of secondary pollution and chemical residue, and ensuring safe and reliable effluent.

Reliable and durable structure: The equipment chamber is made of specially processed food grade 304 stainless steel, and the interior is polished to enhance UV reflectivity, ensuring that the water flow is evenly irradiated and achieving the best sterilization effect.

Widely applicable: It is an ideal and essential equipment for preparing pure water and high-purity water in industries such as electronics, medicine, food, chemical, beverage, cosmetics, etc.

Economic convenience: The device is designed horizontally and features small size, low power consumption, long lifespan, and easy operation. Users only need to regularly replace UV sterilization lamps and clean quartz sleeves, with low maintenance costs.

This device consists of ultraviolet lamps, high-quality quartz tubes, ballasts, stainless steel chambers, and other components, and provides multiple specifications and models for users to choose from to meet different water treatment flow rates and process requirements

What are the disadvantages of UV water sterilizer?

- No sustained sterilization ability: UV disinfection belongs to instantaneous disinfection and only works when the internal illumination is set; If the treated water encounters secondary pollution during storage or transportation and cannot be continuously cherished!

- The disinfection effect is significantly affected by water quality: If the turbidity of the water is high (usually requiring the inlet turbidity to be ≤ 5 degrees, or according to French requirements, ≤ 15 degrees), the color is deep, or it contains a lot of suspended solids, it will primarily hinder or attract ultraviolet rays, thereby significantly reducing the disinfection effect! The content of impurities such as iron and manganese in water should also be controlled at a lower level (such as iron content ≤ 0.3mg/L)!

- Cannot remove non biological pollutants: Ultraviolet radiation can only kill microorganisms and has no effect on removing heavy metals, chemical pollutants, etc. that can exist in water !

What are the application and maintenance of UV water sterilizer?

The operation of ultraviolet disinfectors is very extensive, covering various water management fields such as food and beverage processing, residential drinking water, aquatic reproduction, medical sewage, municipal sewage, etc.

It is crucial to ensure its continuous and efficient operation and regular maintenance:

– Water quality pretreatment: If the original water has high turbidity or suspended solids, it must be pretreated through filtration or other methods to make the water clear;

– Clean the quartz casing on schedule: Hardness materials such as calcium and magnesium in water may form scale on the surface of the quartz casing, affecting UV transmission! Regular cleaning is required based on the water quality condition (can be done by wiping with 75% alcohol or using the built-in automatic cleaning device);

-Timely replacement of ultraviolet lamp tube: Even if the lamp tube can still light up, its ultraviolet output intensity will decay with prolonged application time; It is recommended to replace the light tube in a timely manner according to the instructions or control system reminders (such as after reaching the accumulated task time)!

– Safe operation: Do not directly look at the lit ultraviolet lamp with the naked eye during operation, as intense ultraviolet radiation can cause damage to the eyes and skin. Before any maintenance operation, ensure that the equipment is powered off;

Which is better, UV or RO?

UV disinfection and reverse osmosis water purifiers are not simply a “one or two” relationship, they are often designed to work together.

-The advantage of ultraviolet disinfection lies in its efficient sterilization: it is very effective in inactivating bacteria and viruses, such as Cryptosporidium and Giardia, which have strong resistance to conventional chlorine disinfection, and ultraviolet radiation can also effectively treat them. The entire process does not add any chemicals, so there will be no harmful by-products, nor will it change the taste and chemical composition of the water.

-The advantage of reverse osmosis technology lies in deep purification: the filtration accuracy of reverse osmosis membranes is extremely high, which can effectively remove chemical pollutants such as heavy metal ions, excessive minerals, pesticide residues, etc. from water. If you live in an area with high water hardness or are concerned about chemical pollution, reverse osmosis can provide more comprehensive protection.

– Combination use yields better results: In many high-quality household or commercial water purification systems, most dissolved impurities and pollutants are usually removed through reverse osmosis technology, and then irradiated with ultraviolet lamps before the final effluent. This can ensure pure water quality while also ensuring foolproof microbial indicators, providing a dual guarantee.

| Characteristics | Ultraviolet (UV) Disinfection | Reverse Osmosis (RO) Technology |

|---|---|---|

| Core principle | Using ultraviolet light to destroy the DNA of microorganisms, making them unable to reproduce | Using high pressure to pass water through a semi permeable membrane, filtering out impurities |

| Main functions | Efficient sterilization and virus inactivation | Removal of various dissolved impurities, heavy metals, and chemical pollutants |

| Processing accuracy | does not change the physical and chemical properties of water | produces high-purity pure water |

| Advantages | No chemical additives, instant disinfection, no impact on taste | Comprehensive purification, extremely high purity of effluent |

| Limitations | No sustained bactericidal ability, unable to remove chemical pollutants | Generating wastewater, requiring electricity, relatively high cost |

Does UV light really sanitize water?

The core of a UV water disinfectant is a lamp tube that can emit specific wavelengths of ultraviolet light (usually in the UVC band, around 265 nanometers, with the highest sterilization efficiency). When water flows through a quartz glass sleeve surrounding the lamp tube, microorganisms such as bacteria and viruses are exposed to ultraviolet light. This radiation penetrates the cell walls of microorganisms, damaging their DNA or RNA structures, causing them to immediately lose their ability to reproduce and cause disease, thus achieving disinfection purposes.

To ensure disinfection effectiveness, the following points need to be noted:

-Water quality pretreatment: Turbidity, suspended solids, and chromaticity in water can block or absorb ultraviolet light, significantly affecting disinfection effectiveness. Therefore, before UV disinfection, it is best to filter the water to make it clear.

-Radiation dose: The disinfection effect depends on the combined effect of radiation intensity and time. It is necessary to ensure that the equipment has sufficient power and irradiation time to kill the target microorganisms.

Summary

The choice of technology or combination depends entirely on your water source situation and core needs: If the water quality is acceptable, your main goal is to ensure the safety of drinking water microorganisms (such as killing bacteria and viruses), and UV sterilizers are an efficient and environmentally friendly choice. If the water quality is poor and you need to comprehensively improve it by removing scale, heavy metals, chemical pollutants, etc., then a reverse osmosis water purifier is a more suitable foundation. *In order to obtain the highest quality drinking water, the combination of reverse osmosis and ultraviolet radiation can simultaneously balance chemical purity and biological safety, making it one of the most thorough solutions currently available.

I hope this information can help you make wise decisions. If it is convenient for you to disclose the specific scenarios in which you are considering using water purification equipment (such as daily household drinking water or treating well water, etc.), perhaps we can provide solution for you.

Get A Quote Now!

المنتجات ذات الصلة