20 FT Containerized Water Treatment Plants

- Easy to transport and quickly deploy;

- Automated control, easy to operate;

- Low energy consumption, low operating costs;

- Compact structure, suitable for use in harsh environments;

- Easy to maintain, long service life;

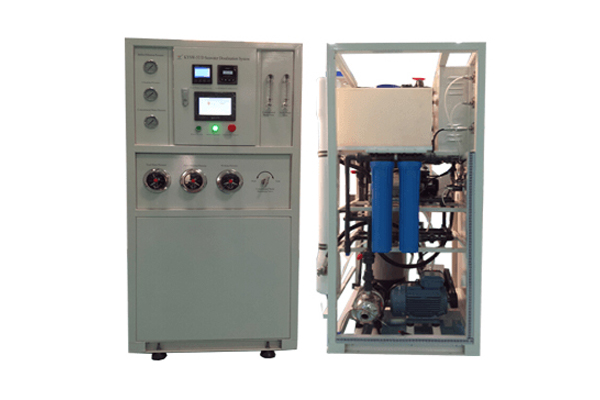

KYsearo 20 ft containerized water treatment plant is a portable, modular desalination system that incorporates a reverse osmosis (RO) salt water and briny water desalination system right into a typical 20 ft containerized (about 6 metres in length). Its core function is to convert seawater/brackish water into freshwater meeting drinking water criteria, making it appropriate for freshwater supply in remote areas, islands, ships, or emergency rescue circumstances.

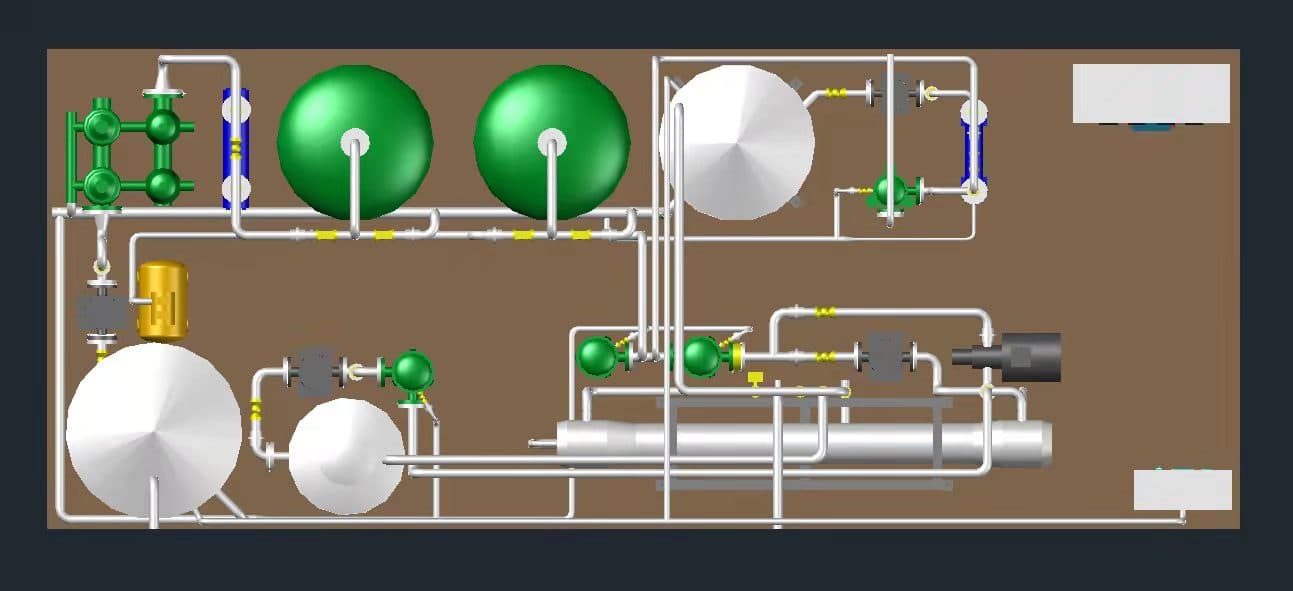

The systems adopts a fully integrated style, incorporating all elements of the desalination procedure, mainly consisting of:

- Pre-treatment system: multi-media filter, precision filter;

- High-pressure system: high-pressure pump (approximately 6.5 MPa);

- Reverse osmosis system: reverse osmosis membranes (with a desalination rate ≥99.5%);

- Post-treatment system (optional): pH adjustment, disinfection unit;

- Control system: PLC or intelligent control system;

- Auxiliary components: Corrosion-resistant piping, insulation layer , air conditioning.

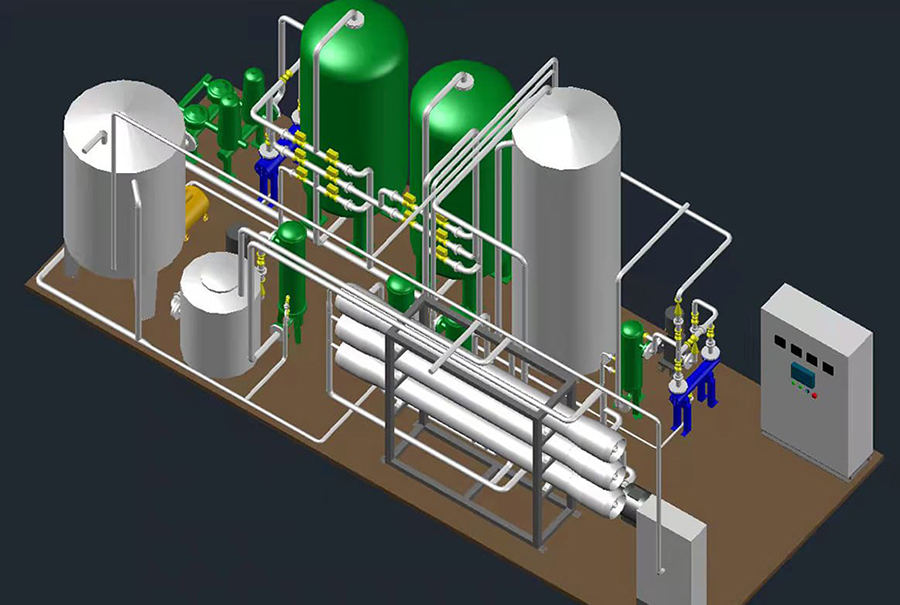

20 FT Containerized water treatment plants working principle

The functioning concept of the 20-foot container salt water desalination tools is reverse osmosis membrane layer separation innovation (Reverse Osmosis, RO), which literally removes salts and impurities from salt water. The details process is as complies with:

Pretratamiento: Seawater first gets in a multi-media filter (to remove huge fragments, put on hold solids, sand, and so on), after that travels through a precision filter (to remove colloids, organic matter, and various other microscopic pollutants), thus minimizing salt water turbidity and safeguarding the subsequent reverse osmosis membrane layers.

High-pressure pressurisation: The pre-treated salt water is pressurised by a high-pressure pump (operating stress approximately 6.5 MPa), going beyond the osmotic stress of seawater.

Reverse osmosis separation: The pressurised seawater passes through reverse osmosis membrane layer components (core parts are high-desalination-rate membranes from brands such as Dow Chemical and Hydranautics), where only water molecules can pass through the membrane pores, while salts, microbes, hefty metal ions, etc are preserved, forming concentrated brine that is discharged; the freshwater that goes through the membrane layer goes into the item water tank.

Post-treatment (optional): Some systems may adjust the pH or decontaminate the item water to more boost water high quality, inevitably generating freshwater that satisfies the requirements of the ‘Hygienic Standards for Alcohol Consumption Water’ (GB5749-2022).

Especificaciones de los sistemas de desalinización en contenedor de 20 pies

| Modelo | Modelo de membrana*cantidad | ProducciónT/D | Tasa de desalinización/% | Peso/kg | Presión de funcionamiento/Mpa | Potencia |

|---|---|---|---|---|---|---|

| KYCT20-20.8 | 4040×8 | 20.8 | 98 | 2800 | 3.5-6.5 | 220/50-60 HZ – 380/50-60 HZ |

| KYCT20-26 | 4040×10 | 26 | 98 | 2860 | 3.5-6.5 | |

| KYCT20-31.2 | 4040×12 | 31.2 | 98 | 2920 | 3.5-6.5 | |

| KYCT20-41.6 | 4040×16 | 41.6 | 98 | 3030 | 3.5-6.5 |

Your premier containerized water treatment plants solution expert

KYsearo containerized series reverse osmosis water system made for small-scale plants or long-distance delivery. By making pre-designed module-size plants, totally put together in typical 20ft container. It would bring the adhere to ease for consumers:

- Más comodidades para el embalaje y el transporte

- No es necesario dejar espacio ni construir un nuevo arquitecto para instalar el sistema

Sólo hay que enviar el contenedor al lugar donde se necesita el agua potable y, tras una breve sesión de formación, los trabajadores encargados están listos para producir agua potable de alta calidad a los pocos días de la entrega.

What are the features of containerized water treatment plants?

- Compact and portable: Integrated into a 20-foot container, little in dimension and light-weight (e.g., some versions have a completely dry weight of roughly 4– 10 tonnes), very easy to move, lift, and deploy promptly, without the demand for massive civil engineering.

- High-efficiency desalination: Makes use of reverse osmosis modern technology with a desalination price going beyond 99.5%, producing water with a conductivity of <1200 μS/cm

- Automated control: Supports one-button start/stop, automatic cleaning (e.g., automatic cleaning when the pressure differential alarm of the multi-media filter is triggered), and fault alarms (high/low pressure protection), with simple operation requiring only 1-2 people for maintenance.

- Versatile Applications: Suitable for residential water supply on islands, ship replenishment water, industrial production water in coastal areas (e.g., concrete mixing, mining), or emergency rescue (e.g., disasters, remote regions).

- Energy-Efficient Design: Some models are equipped with energy recovery devices, reducing electricity consumption per tonne of water (e.g., models with a production capacity of 72 m³/day have an electricity consumption of approximately 3-5 kWh per tonne of water).

What are the application of containerized water treatment plants?

- Island and coastal residents: Addressing the ‘freshwater shortage’ issue on islands, providing stable drinking water for daily use;

- Ships and offshore platforms: Providing onboard freshwater for fishing vessels, merchant ships, and offshore drilling platforms;

- Coastal industries: Meeting the production water needs of coastal factories (e.g., steel, chemical industries);

- Emergency response: Rapidly deploy to provide temporary freshwater after disasters such as earthquakes or tsunamis.

Responda aquí a su pregunta

Las plantas en contenedores tienen muchas ventajas sobre las instalaciones empotradas:

- Fácil transporte

- Instalación rápida

- Útil para entornos exteriores adversos

El diseño del proceso de las plantas de tratamiento de agua depende siempre de la calidad del agua bruta. Las unidades de ósmosis inversa suelen requerir un pretratamiento para los siguientes parámetros:

- Sólidos en suspensión

- COT, DQO/DBO, hidrocarburos

- Hierro y manganeso

- Dureza

Obtenga una solución ahora

Productos relacionados