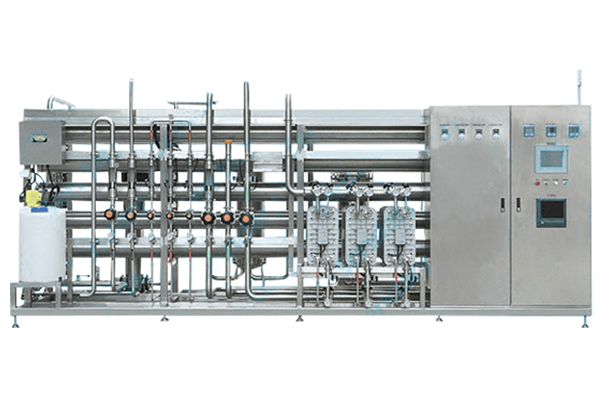

RO EDI Water Treatment Solution Electrodeionization Water System

- Removes chemical handling/disposal hazards/costs.

- Provides constant high-purity water without downtime.

- Minimal waste vs. considerable chemical waste from IX.

- Reduced Operational Expenses and lasting expenses.

- Smaller sized Footprint requires less room.

Osmoză inversă cu două treceri + preparare EDI (caracteristicile procesului de purificare a apei)

1. Suitable for raw water salinity compared Height regions;

2. Product water conductivity is better;

3. One-time investment of less;

4. Lower operating costs;

Technical Details Of RO EDI Water Treatment

| Valoarea PH | 7.5 - 9 |

|---|---|

| Temperatura | 15℃–35℃ |

| Presiunea apei de alimentare (DIN) | 0,15 - 0,4MPa |

| Presiunea de alimentare cu apă sărată | 0,10-0,3MPa |

| Presiunea apei din produs (DOUT) | 0,05 - 0,25MPa |

| Presiunea efluentului de apă sărată (COUT) | 0,02 - 0,2MPa |

| Duritatea apei de alimentare | < 1.0ppm (CaCO) |

| Alimentarea apei cu material organic | TOC < 0.5ppm |

| Siliciu pentru apa de hrănire | SiO2 < 0.5ppm |

| Total apă de alimentare CO2 | < 3ppm |

What is RO Electrodionization (EDI)?

Electrodionization (EDI) is an advanced water therapy technology for generating high-purity and ultrapure water. It surpasses standard deionization by getting rid of chemical regrowth of ion exchange materials. Usually following reverse osmosis (RO), EDI acts as a brightening step, removing residual ions, trace element, and weakly ionized varieties not completely declined by RO. Compared to standard mixed-bed ion exchange, EDI uses continuous operation, decreased chemical handling, and a smaller sized footprint, making it favored for crucial applications.

How is Fundamental Principles of EDI?

EDI’s efficiency results from integrating electrodialysis, ion exchange, and electrochemical regeneration. It makes use of a direct existing (DC) electric field to move ions. Water flows via compartments with ion exchange resins that capture dissolved ions. Ion-selective membrane layers (cation-exchange and anion-exchange) enable specific ions to pass, creating purified (dilute) and concentrated streams. The electrical area additionally divides water molecules (H ₂ O → H ⁺ + OH ⁻) within resin compartments. These H ⁺ and OH ⁻ ions constantly restore the materials in situ , removing the requirement for exterior chemicals. This continuous regeneration is crucial to EDI, commonly called “Continual Electrodeionization” (CEDI).

Obțineți o soluție acum

How is Electrochemical Processes and Ion Transportation Mechanisms?

The applied DC electrical field drives cations in the direction of the cathode and anions in the direction of the anode. In dilution areas, resins capture ions. Cations exchange for H ⁺ on cation resins, anions for OH ⁻ on anion materials. The electrical field relocates these ions with ion-selective membranes right into concentration compartments. Cation membranes (CEMs) pass only cations; anion membranes (AEMs) pass only anions.

Water splitting takes place where materials and membrane layers meet under the electrical field, creating H ⁺ and OH ⁻ ions that restore resins by displacing caught ions. These impurity ions after that move across membrane layers into the concentrate stream.

Ion transportation in material beds is a two-stage procedure. High material conductivity (2-3 orders higher than deionized water) improves existing flow and ion motion. Electrochemical processes face overpotentials (activation, focus, resistance). Separation involves electrokinetics and electrosorption.Methods like chronopotentiometry, I– V contours, and EIS define transport.

What are EDI Heap Layout and Component Components?

An EDI component (pile) contains rotating compartments in between an anode and a cathode. These compartments, specified by membrane layers, contain ion exchange products. Key compartments are:.

- Dilution: Feedwater flows right here; deionization happens. Packed with combined or layered materials that catch ions.

- Focus: Nearby compartments where ions gather after passing membranes, creating the concentrate stream.

- Electrode: At pile ends, housing anode and cathode. Electrolyte carries present and promotes electrode reactions.

Spacers develop flow networks and assistance membranes/resin. The regular pattern alternates CEM, dilution (material), AEM, concentration. Electrodes provide the DC field. Stacks range by including areas.

How is Ion-Exchange Membranes and Resins in EDI?

EDI efficiency counts greatly on membrane and resin properties and interactions.

Ion-Exchange Membranes: . Two kinds are utilized:.

- Cation Exchange Membranes (CEMs): Taken care of unfavorable fees; absorptive only to cations.

- Anion Exchange Membranes (AEMs): Repaired favorable costs; permeable only to anions.

Perfect membranes have high permselectivity, reduced resistance, and good security. Structure and make-up impact selectivity. Water uptake increases conductivity but may lower selectivity. Cross-linking equilibriums conductivity and selectivity. Heterogeneous membrane layers offer mechanical stamina [15] Bipolar membrane layers improve water splitting in some designs.

Ion-Exchange Resins: . Materials in dilution areas are crucial, especially for thin down feeds. They increase conductivity and aid ion transportation to membranes.

- Types: Strong acid cation (SAC) and solid base anion (SBA) prevail, commonly blended. Weak acid/base resins might be used in layered beds for regeneration performance.

- Properties: Conductivity, bit size, and capability are crucial. Smaller sized grains provide faster kinetics yet greater stress decrease. Optimized cation-to-anion proportion (e.g., 40:60) equilibriums elimination.

- Obstacole: Fouling by solids, organics, oils, or bacteria minimizes efficiency. Oxidants deteriorate materials. Steels like iron catalyze oxidation.Normal cleansing (caustics for anion, acids/reducing agents for cation) is needed. Resin life expectancy is 4-8 years depending on regeneration and water quality.

Novel materials like zwitterionic resins and compound bed layouts are being checked out.

Feedwater Quality Demands and Pretreatment

Efficient EDI procedure calls for top quality feedwater, normally RO permeate. RO is the only suggested feed.

Essential criteria:.

- Conductivitate: Reduced, commonly < 20 µS/ centimeters.

- Solidity (as CaCO SIX): Very reduced, < 0.5 ppm, preferably < 0.1 mg/L. Stops scaling.

- Silica (SiO ₂): Reduced, ideally < 0.5 ppm [2] Greater degrees (> 2 ppm) create scaling.

- Total Organic Carbon (TOC): Reduced, typically < 0.5 ppm, < 5 ppb for ultrapure [2] High TOC creates fouling.

- Chlorine (Cl Two): Very low, < 0.05 ppm. Oxidants damages membranes/resins.

- Ozone (O SIX): Really reduced, < 0.02 ppm.

- Multivalent Metals (Fe, Mn): Very reduced (< 0.01 ppm Fe, 98%. Silica is weakly ionized and can appear initial.

- Boron Removal: > 96% attainable [31] Additionally weakly dissociated, can break through.

- CARBON MONOXIDE Two Elimination: Efficient, > 99% reported [31] CO ₂ converts to bicarbonate/carbonate and is removed.

- Weakly Ionized Types: EDI properly gets rid of species like silica and carbonic acid. The electrical area advertises ionization for elimination.

Item quality depends substantially on feedwater top quality. Contaminants like solidity, organics, particulates, steels, oxidants, and carbon monoxide two negatively impact efficiency. Efficient pretreatment is crucial. Functional elements (flow, voltage/current, temperature level) also impact efficiency. Longer home time improves removal of weakly ionized types. Online conductivity/resistivity monitoring assesses purity. EDI lowers ionic types to ppb levels.

What are the applications of EDI water treatment?

EDI’s ability to generate high-purity water continually without regrowth chemicals leads to wide adoption.

- Power Generation: Produces demineralized water for boiler feed, vital for stopping scaling/corrosion.Made use of for NOx decrease in gas generators.

- Pharmaceuticals: Fulfills pharmacopoeia criteria (USP, EP) for detoxified water and WFI. Preferred for chemical-free, continual high-purity manufacturing conference low conductivity/TOC requires.]

- Microelectronics: Supplies ultrapure water with incredibly reduced pollutants for semiconductor fabrication.

- Food and Beverage: Demineralizes water for manufacturing, components, and process use, making certain high quality and avoiding scaling.

- General Industrial: Offers reliable, environmentally friendly demineralized water for production, cleaning, and cooling down.

- Mining and Hydrometallurgy: Made use of for demineralization or careful ion elimination.

- Hospitals and Laboratories: Supplies high-purity water for hemodialysis and analytical/research functions.

- Consistent Quality: Stable product quality over time.

Functional Parameters, Monitoring, and Control

Efficient EDI procedure calls for surveillance and control of vital specifications.

Key Operating Variables: .

- Applied Voltage/Current: Critical for ion transportation and water splitting. Run within recommended arrays; insufficient voltage causes incomplete removal, excessive present causes damage.

- Flow Prices: Control dilute, concentrate, and electrode streams. Flow influences home time and removal efficiency. High flow triggers insufficient deionization; low flow rises scaling threat.

- Healing Rate: Portion of feedwater coming to be item. High recuperation (as much as 97-99%) feasible by reusing concentrate to RO inle.

- Nivelul temperaturii: Affects kinetics, membrane layer conductivity, water splitting. Run within specified array (e.g., 10-38 ° C). Temperature improvement required for resistivity.

Tracking Techniques: .

- Conductivity/Resistivity: Primary look for performance and pureness. Adjustments show scaling, fouling, or material problems.

- Stress Differential: Discovers clogging/fouling in resin bed or channels.

- Electric Specifications: Ensures appropriate voltage/current application.

- Circulation Meters: Essential for controlling circulations and computing healing.

- Water Chemistry: Periodic/continuous checks of feedwater (solidity, silica, CO TWO, TOC, oxidants) make sure pretreatment efficiency.

Control Methods: .

- Specification Optimization: Readjust voltage/current and circulation based on feedwater and preferred pureness.

- Chemical Cleaning (CIP): Routine cleansing with ideal chemicals (acid for scale, others for organics) minimizes scaling/fouling.

- Automated Control: Equipments change criteria based on real-time data to maintain high quality and protect components.

- Precautionary Maintenance: Set up assessments and log activities to recognize concerns very early.

- Pre-treatment Verification: Regularly check upstream systems (RO, conditioners, carbon filters) as feedwater high quality is important.

- Real-time Monitoring/Alerts: Dashboards and informs for variances (high item conductivity, pressure decline) enable quick response.

Appropriate OEM design is important for performance and long life.

Maintenance, Troubleshooting, and Module Long life

Effective upkeep and troubleshooting guarantee long-lasting EDI component efficiency. Problems mainly relate to feedwater top quality.

Usual Operational Issues: .

- Scaling: Mineral rainfall (CaCO FOUR, magnesium silicate) on membranes/resins, usually in the concentrate stream where pH rises. Lowers performance, enhances stress decline, damages elements. Indicators: enhanced stress difference, reduced concentrate circulation.

- Fouling: Buildup of organics, microorganisms, particulates on membranes/resins. Reduces ion migration, enhances resistance. Reduces purity, boosts power usage.

- Material Depletion/Degradation: Materials break down in time from oxidants (chlorine) or metal-catalyzed oxidation (iron). Fragmentation raises pressure drop/clogging.

- Membrane Deterioration: From chemical direct exposure, high temperature, or physical damage. Minimizes permselectivity and removal effectiveness.

Upkeep Procedures: .

- Routine Tracking: Constant tracking of item top quality, stress differential, electric specifications finds problems.

- Feedwater High Quality Confirmation: Examine RO permeate high quality to ensure upstream treatment avoids pollutants.

- Chemical Cleaning (CIP): Necessary for removing scale/fouling. Usage dilute acid for scale; various other chemicals for organic/biological fouling.Follow supplier guidelines to stay clear of damage.

- Oxidant Removal Verification: Make sure total oxidant removal in pretreatment to protect resins/membranes. Display ORP.

- Regular Assessments: Aesthetic checks for leakages or physical damage.

Fixing Guidance: . For wearing away top quality or raised pressure drop:.

- Check Feedwater Quality: Confirm RO permeate meets specs (conductivity, solidity, silica, CO ₂, TOC, oxidants). Concerns indicate upstream issues.

- Monitor Operational Parameters: Inspect flow prices, voltage, current are within array.

- Evaluate for Scaling/Fouling: Raised stress drop/decreased concentrate circulation indicate scaling/fouling. Chemical cleansing is the remedy.

- Examine Electric System: Guarantee stable power and proper voltage/current.

- Inspect for Physical Damages: Seek leakages or damages.

- Think About Resin/Membrane Issues: If cleansing is inefficient and feedwater is good, degradation/damage might need module substitute.

Module Durability: . Life expectancy depends upon:.

- Feedwater High Quality: Consistent, high-quality feed is essential. Surpassing limitations (firmness, silica, oxidants) triggers early problems.

- Running Conditions: Operating within defined arrays protects against stress.

- Maintenance Practices: Routine, efficient cleaning and preventative maintenance expand life.

- Module Design/Quality: Supplier’s component top quality influences toughness.

- Running Hours: Contributes to use.

EDI components last numerous years, however inadequate feedwater or maintenance shortens this. Early detection and aggressive maintenance make best use of longevity.

Obțineți o soluție astăzi!

Rekated Products