Project background

A client in Indonesia was facing issues with high water solidity in their well water. Using water with such high solidity straight could cause scale build-up in pipes and equipment, affecting the life expectancy of manufacturing devices and the normal procedure of the water filtration system. The customer quickly required a water softening equipment with a capacity of 30 m3 per hour. Thinking about the need for constant and steady supply of water, they required a repetitive arrangement with one conditioner in use and one on standby. We took on this job and customized a remedy for them.

Water softening equipment configuration and working principle

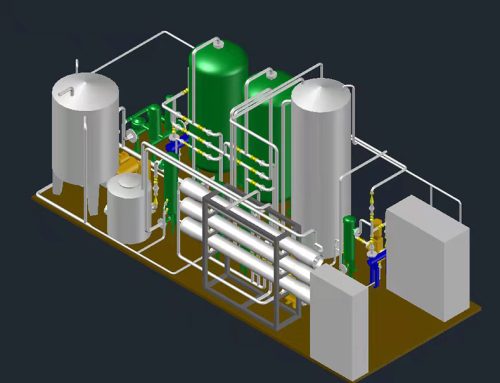

Main Equipment

A dual-unit softening system was chosen, paired with stainless-steel tank and other facilities. The softeners are loaded with ion exchange resin, which uses the adsorption and substitute of calcium and magnesium ions to minimize water hardness. When the resin in the operational conditioner becomes saturated, the standby conditioner instantly activates to ensure constant water supply, while the saturated resin goes through regrowth to restore its softening ability.

Treatment Process

Groundwater from the well is first stored in the storage tank, then pressurized and fed right into the operational conditioner. Via ion exchange by the material, calcium and magnesium ions are removed, reducing water firmness. The softened water meets the requirements for subsequent industrial and domestic use; When the softener requires regrowth, the standby conditioner seamlessly takes over, guaranteeing a secure outcome of 30 tons per hour. The regrowth procedure entails rinsing the material with a salt option to displace the adsorbed calcium and magnesium ions, thereby “restoring” the resin.

Project Challenges and Solutions

Water Quality Compatibility Obstacles

The hardness composition of groundwater in Indonesia is complex, and firmness levels fluctuate considerably at various times. We gathered multiple water samples beforehand, assessed the firmness structure and variation patterns, customized a special formula of ion exchange material, optimized the resin loading process, boosted the adsorption capacity and stability for high-hardness ions, and guaranteed efficient conditioning under varying water quality conditions.

Overseas Adjustment Obstacles

When exporting to Indonesia, we had to take into consideration regional distinctions in voltage, environment, and various other ecological factors. The equipment’s electrical system was redesigned to meet Indonesian voltage requirements, utilizing high-temperature and high-humidity immune elements and protective products. The devices real estate undertook special corrosion-resistant therapy to adapt to Indonesia’s hot and damp environment. Furthermore, technological employees were sent off to the website to guide setup and appointing, making sure the tools’s stable procedure in the local environment.

Project outcomes

The devices was effectively exported to Indonesia and runs stably. The 30T/H treatment ability fulfills the consumer’s water need, with a standby conditioner guaranteeing continuous water supply. The treated water’s hardness is significantly decreased, resolving issues such as equipment scaling and water circulation issues triggered by high water hardness. This has received high recognition from the customer and has actually likewise given us with experience in overseas well water softening projects, helping even more abroad customers resolve water high quality challenges.

Get A Solution Today!